Hollow paddle type sludge drying technique

A technology of sludge drying and hollow blades, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of thermal pollution of washing wastewater, achieve the effect of reducing washing costs and solving thermal pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

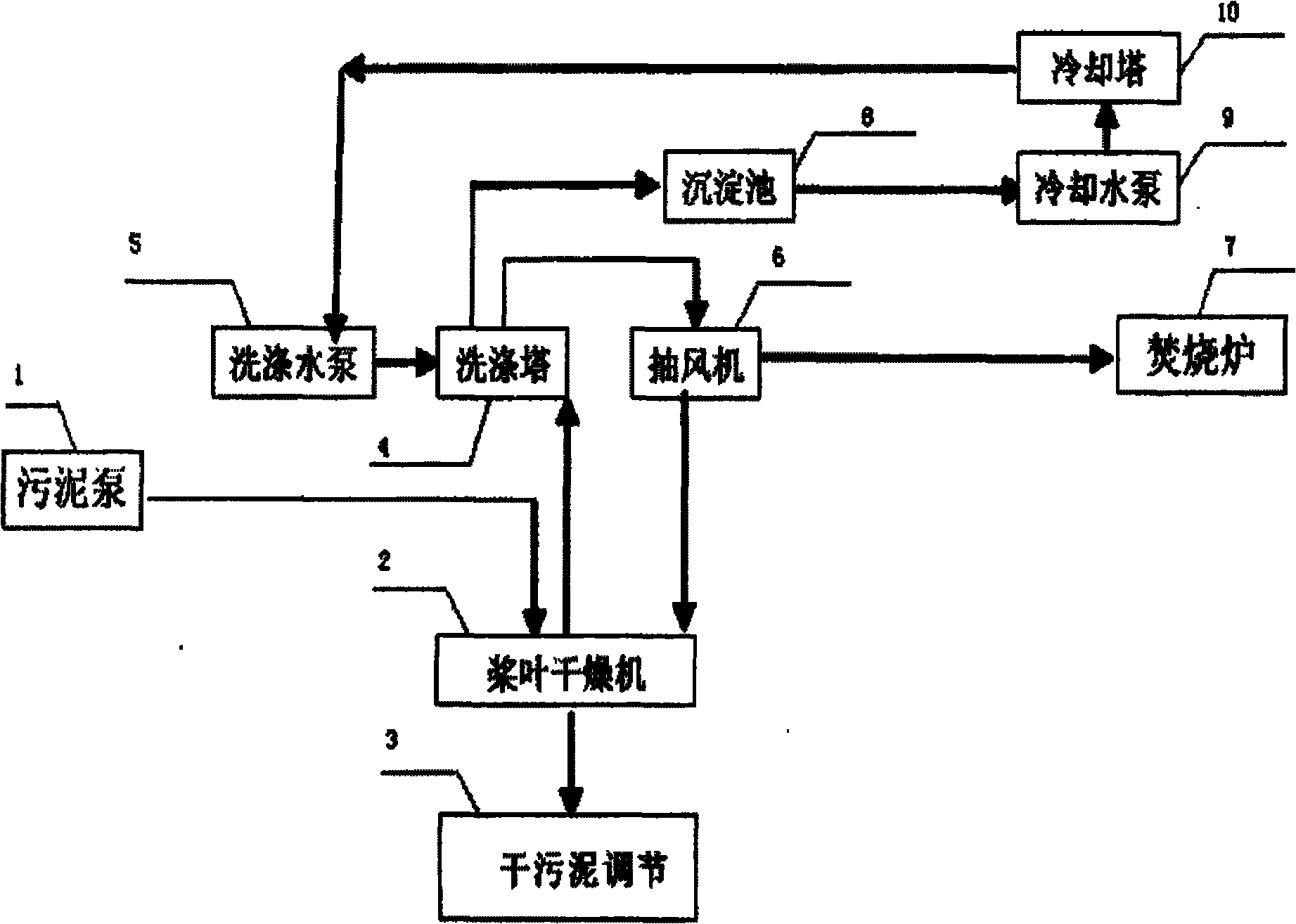

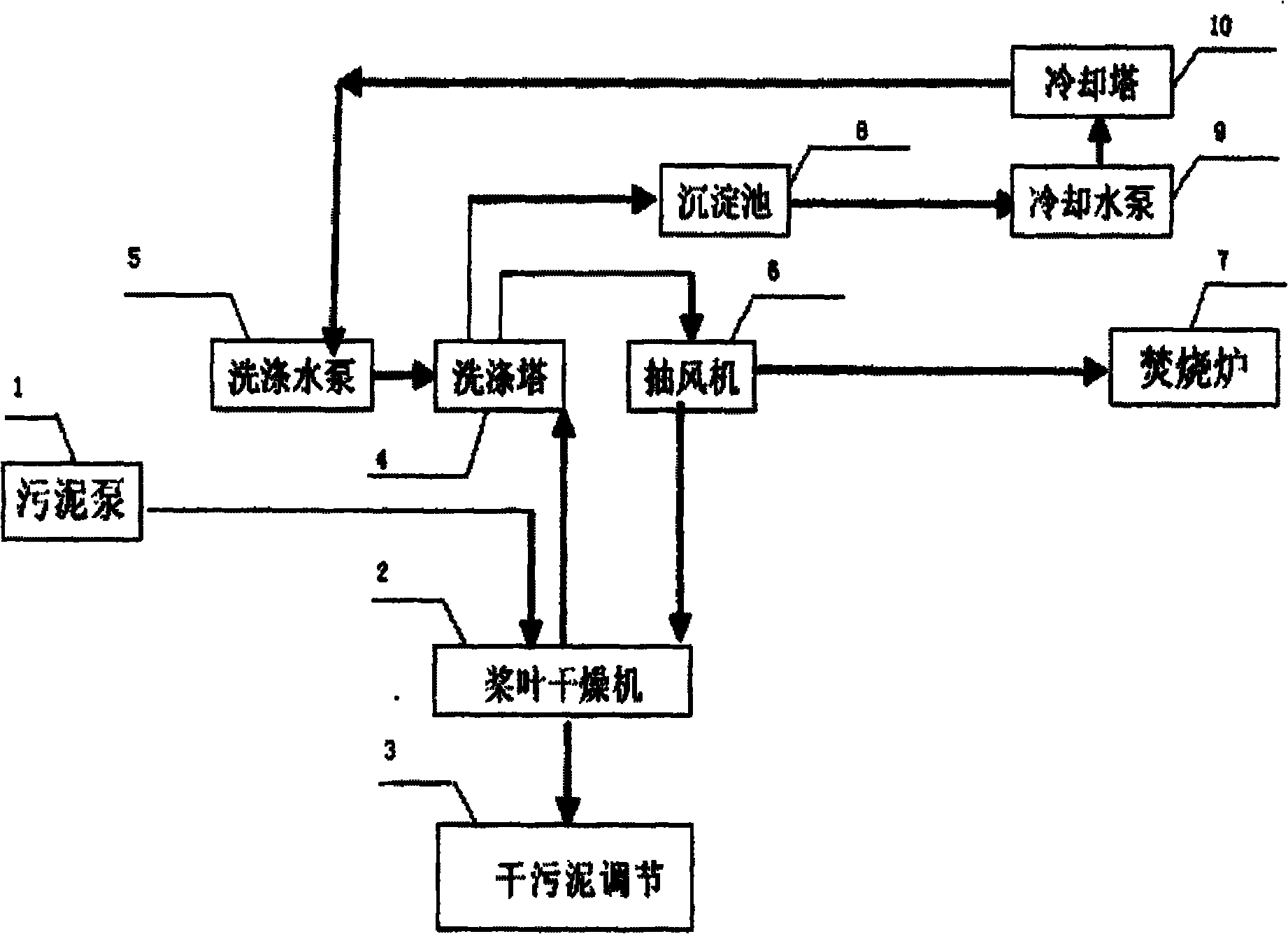

[0013] Such as figure 1 The flow chart of the hollow paddle drying technology shown is firstly the sludge drying process: the wet sludge is transported to the wet sludge storage bin through the sludge treatment plant, and then transported to the paddle dryer 2 through the sludge pump 1, In the paddle dryer 2, the steam transfers heat to the wet sludge, so that the water in the wet sludge can evaporate, and the dried wet sludge is discharged from the bottom of the paddle dryer, and temporarily stored in the dry sludge conditioning bin 3 Afterwards, it is sent to the incinerator 7 for incineration disposal by the feeding screw conveyor.

[0014] Drying carrier gas process: the drying gas generated during the drying process of the paddle dryer is mixed with the drying carrier gas to form a wet carrier gas. In the scrubber 4, the wet carrier gas contacts with a large amount of sprayed washing cooling water and rapidly cools down. While the water vapor in the wet carrier gas is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com