Spiral square paper tube manufacturing equipment

A manufacturing equipment and a spiral technology, applied in the field of spiral square paper tube manufacturing equipment, can solve the problems of low strength and hardness, inaccurate dimensions, and high production cost, and achieve high strength and hardness, simple equipment and process structure, and a wide range of applications. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

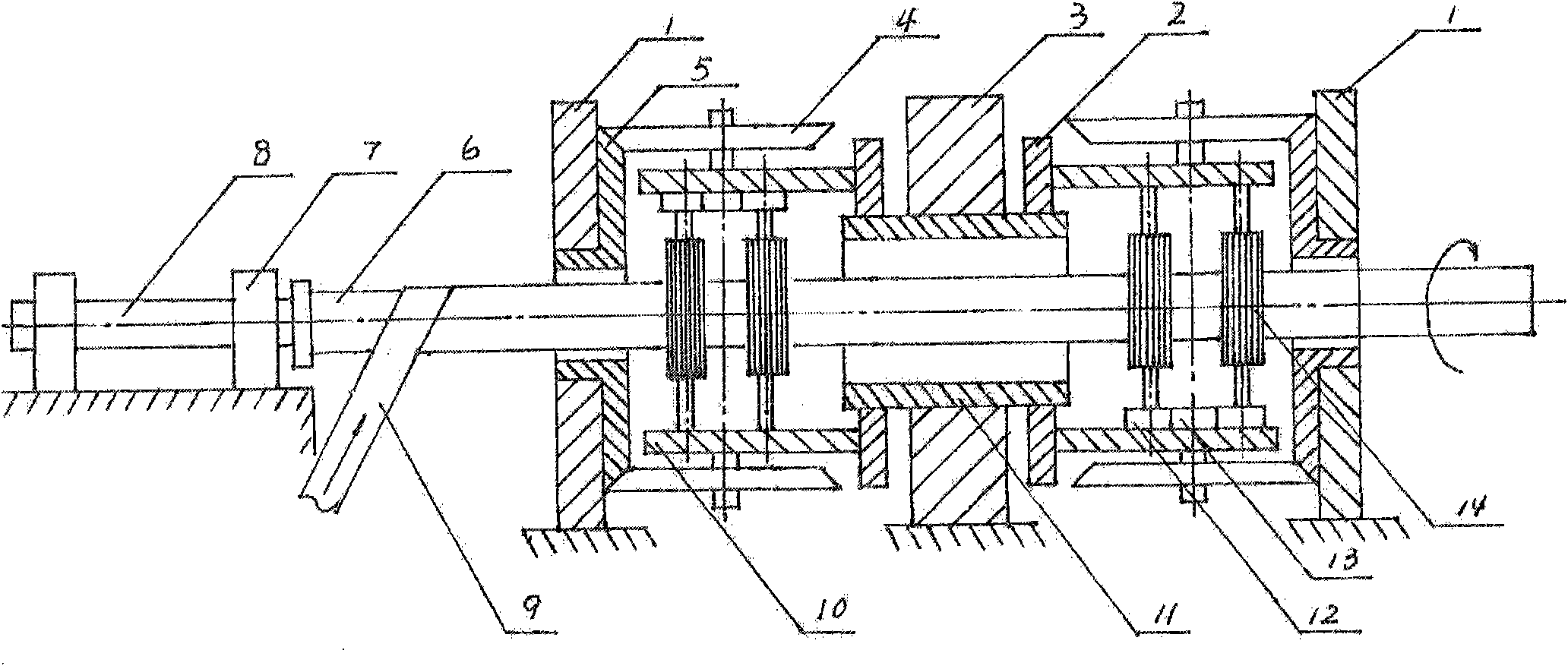

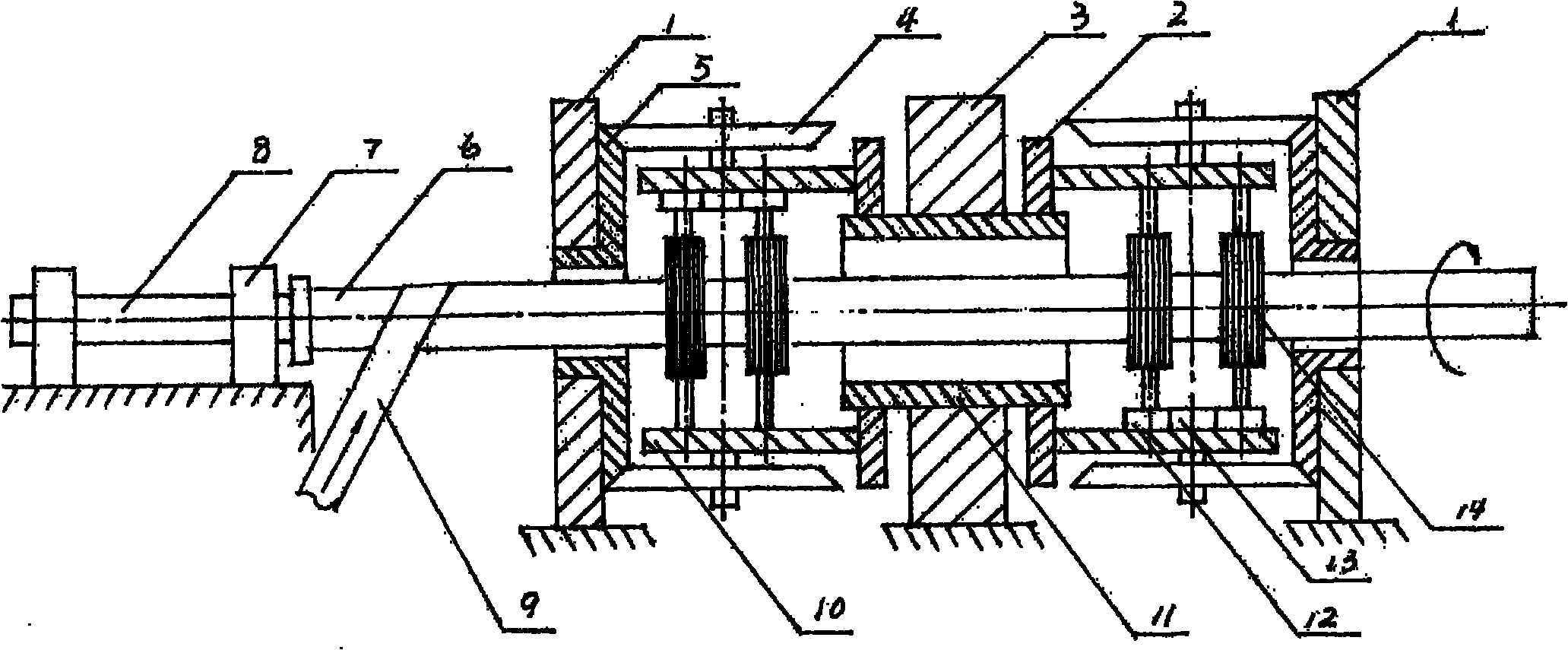

[0016] like figure 1 As shown, this embodiment includes two bevel gear seats 1, two transmission sprockets 2, a sprocket seat 3, two driven bevel gears 4, two fixed bevel gears 5, a square tube inner mold 6, two bearings Seat 7, a square tube internal mold connecting shaft 8, a slitting paper 9, four gear connecting plates 10, a hollow shaft 11, two pinch roller shaft transmission gears 12, two pinch wheel shaft driving gears 13, eight pinch wheel shafts 14 , wherein only four pinch roller shafts 14 are shown in the figure, among the eight pinch wheel shafts 14, the first four pinch wheel shafts 14 squeeze the two sides of the square paper tube, and the last four pinch wheel shafts 14 squeeze the remaining two sides of the square paper tube. face. The fixed bevel gear 8 is fixed on the bevel gear seat 1, the passive bevel gear 4 meshes with the fixed bevel gear 5; the transmission sprocket 2 is fixed on the hollow shaft 11, and the hollow shaft 11 is fixed on the sprocket sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com