Self-rotating clamping device used for rapidly changing upper anvil for forging press

A technology of clamping device and forging press, which is applied in forging/pressing/hammer device, forging/pressing/hammering machinery, manufacturing tools, etc., which can solve the problem of slow anvil changing speed, complex structure and insufficient force on the clamping shaft. Balance and other issues to achieve the effect of improving speed, movement coherence, and force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

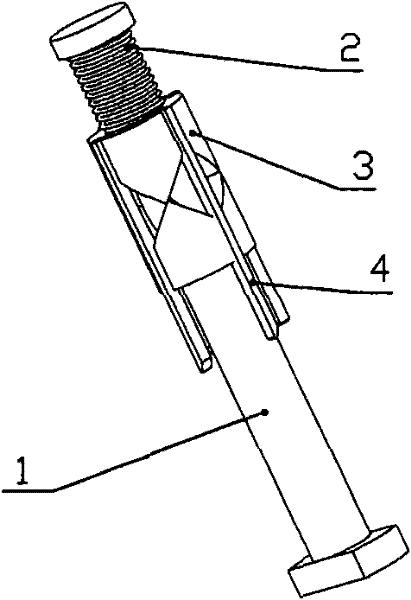

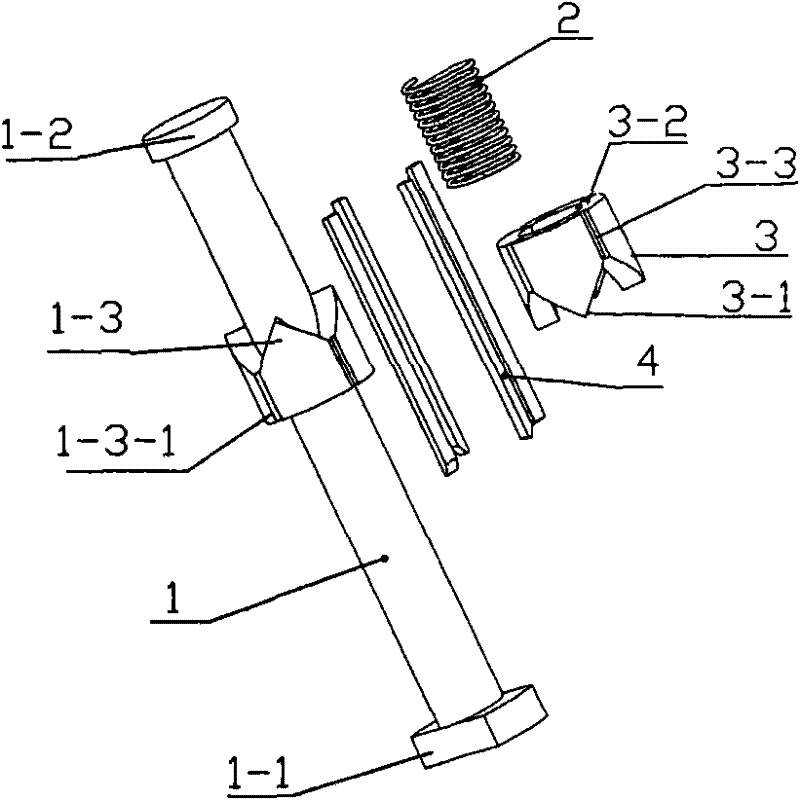

[0013] Such as figure 2 , 3 As shown, a self-rotating clamping device for quick-change upper anvil of a forging press includes: a clamping shaft 1 whose lower end is a T-shaped hook head 1-1, and the top end of the clamping shaft 1 has a shoulder 1- 2. The middle part is equipped with teeth 1-3 meshing with the moving sleeve 3. The upper end of the moving sleeve 3 is a plane 3-2, and the lower end is a tooth 3-1. The moving sleeve 3 is set above the teeth 1-3 of the clamping shaft 1, and moves A compression spring 2 is provided between the plane 3-2 at the upper end of the sleeve 3 and the shoulder 1-2 at the top of the clamping shaft 1, and the surface of the moving sleeve 3 is symmetrically provided with four moving sleeve chute 3-3, clamping The surface of the teeth 1-3 of the shaft 1 is provided with four clamping shaft chute 1-3-1 corresponding to the moving sleeve chute 3-3, the moving sleeve chute 3-3 and the clamp The tight shaft chute 1-3-1 is respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com