Non-belt fiber and large-core number single-layer stranding optical cable

A large number of cores, single-layer technology, applied in the field of communication, can solve the problems of small thickness, large outer diameter of optical cable, high cost of optical cable, and achieve the effects of excellent high and low temperature performance, low investment in production equipment and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

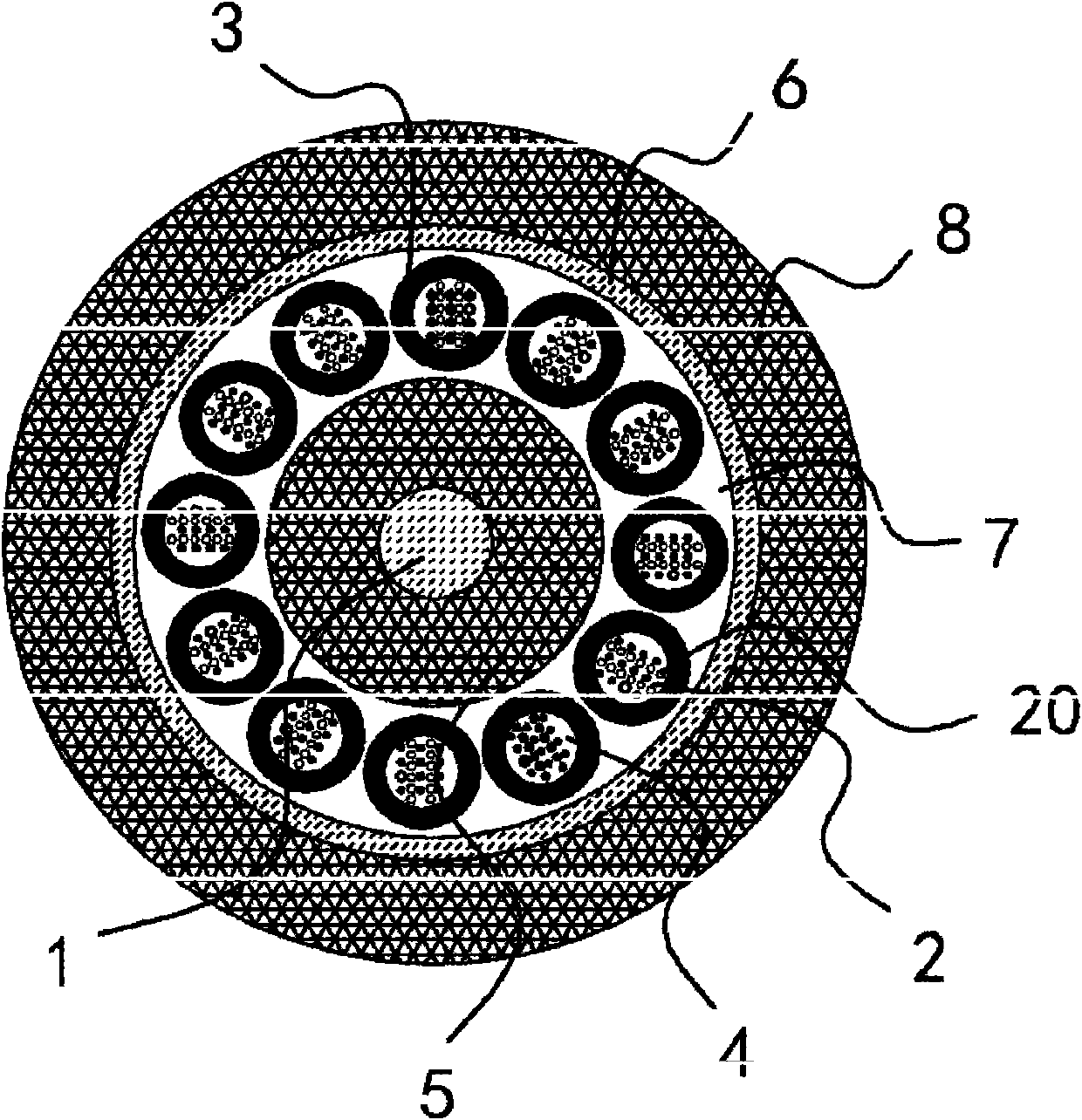

[0013] Such as figure 1 As shown, the single-layer twisted optical cable with large number of cores without fibers includes a central strength member 1 and several optical fiber bundles 2 . A loose tube 3 is respectively sheathed on the periphery of each fiber bundle 2 , and a fiber paste 4 enclosing the fiber bundle 2 is arranged inside the loose tube 3 . The number of cores of the optical fibers 20 in each optical fiber bundle 2 is no more than 24. The optical fiber bundle 2 is any one of colored ring optical fiber, ordinary optical fiber or a combination of both. The total number of cores of the optical fibers 20 in the optical fiber bundle 2 does not exceed 288.

[0014] A cushion layer 5 is provided on the periphery of the central reinforcement 1, and the above-mentioned loose tubes 3 are twisted in a single layer around the central reinforcement 1, and a metal layer covering each loose tube 3 is provided on the periphery of the twisted loose tubes 3. The composite str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com