Inner-ring upright four-axis stable platform

A stable platform and upright technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of compactness, rigidity and lack of stability accuracy, and achieve the effect of compact structure, reduced overall size and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

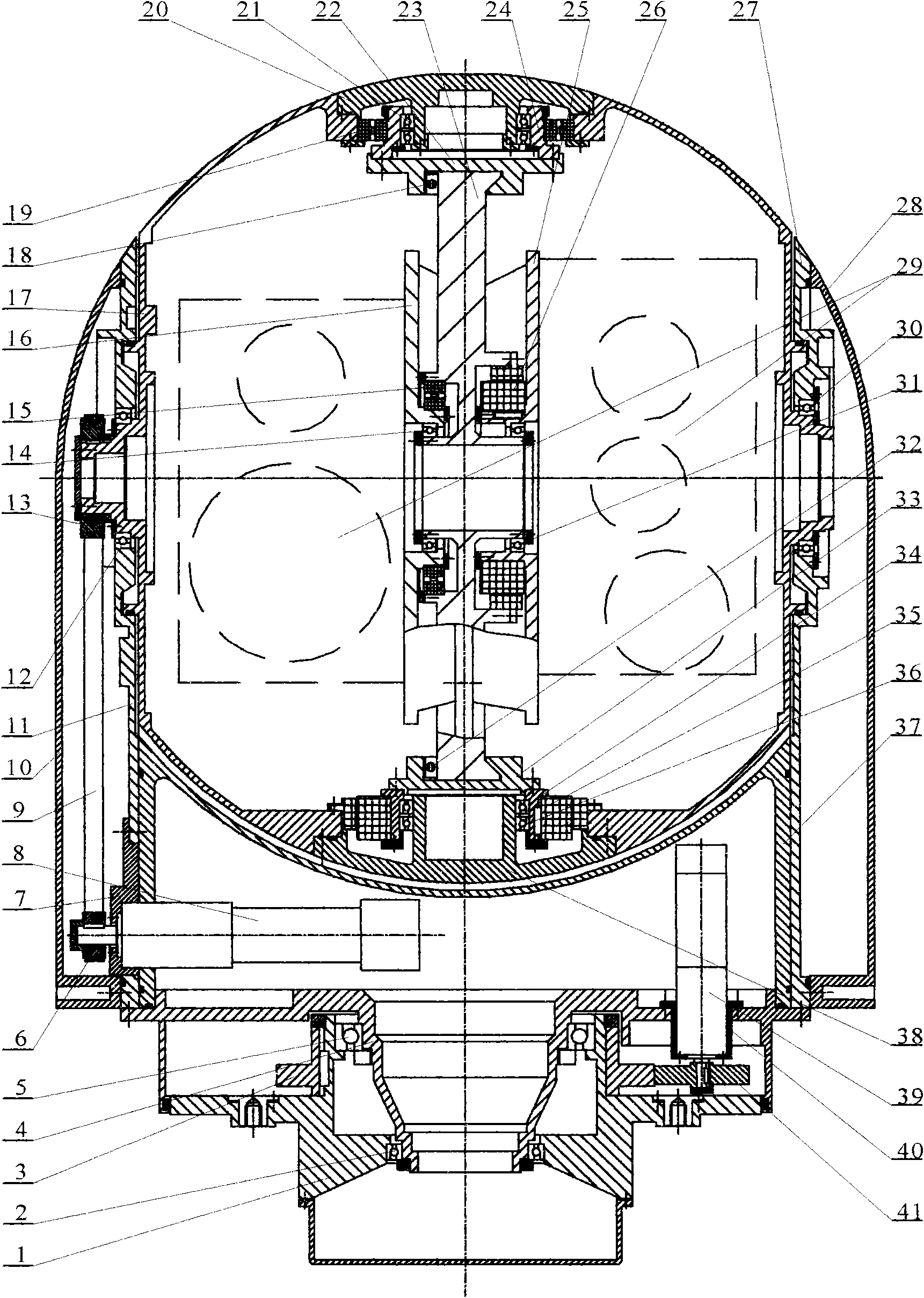

[0025] Such as figure 1 As shown in -6, an inner ring vertical four-axis stable platform is composed of an outer azimuth slewing mechanism, an outer pitch slewing mechanism, an inner azimuth slewing mechanism and an inner pitch slewing mechanism: the outer azimuth slewing mechanism includes a fixed installation The outer azimuth housing 1 on the carrier, the outer azimuth housing 1 supports an outer azimuth shaft 4 through bearings 2, 5; the outer azimuth housing 1 is connected with the outer azimuth shaft 4 through gear transmission: the upper end of the outer azimuth shaft 4 is installed near the edge An outer azimuth servo motor 39 with a pinion 41, the pinion 41 meshes with the large gear 3 fixed on the outer azimuth housing 1; the outer pitch mechanism includes an outer pitch seat 37 fixed on the outer azimuth shaft 4; The left side of pitch seat 37 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com