Safety stove

A stove and safety technology, applied in the field of stoves, can solve the problems of hidden safety hazards, inconvenient use for users, high boiler cost, etc., and achieve the effect of meeting the needs of daily life and being safe and reliable in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

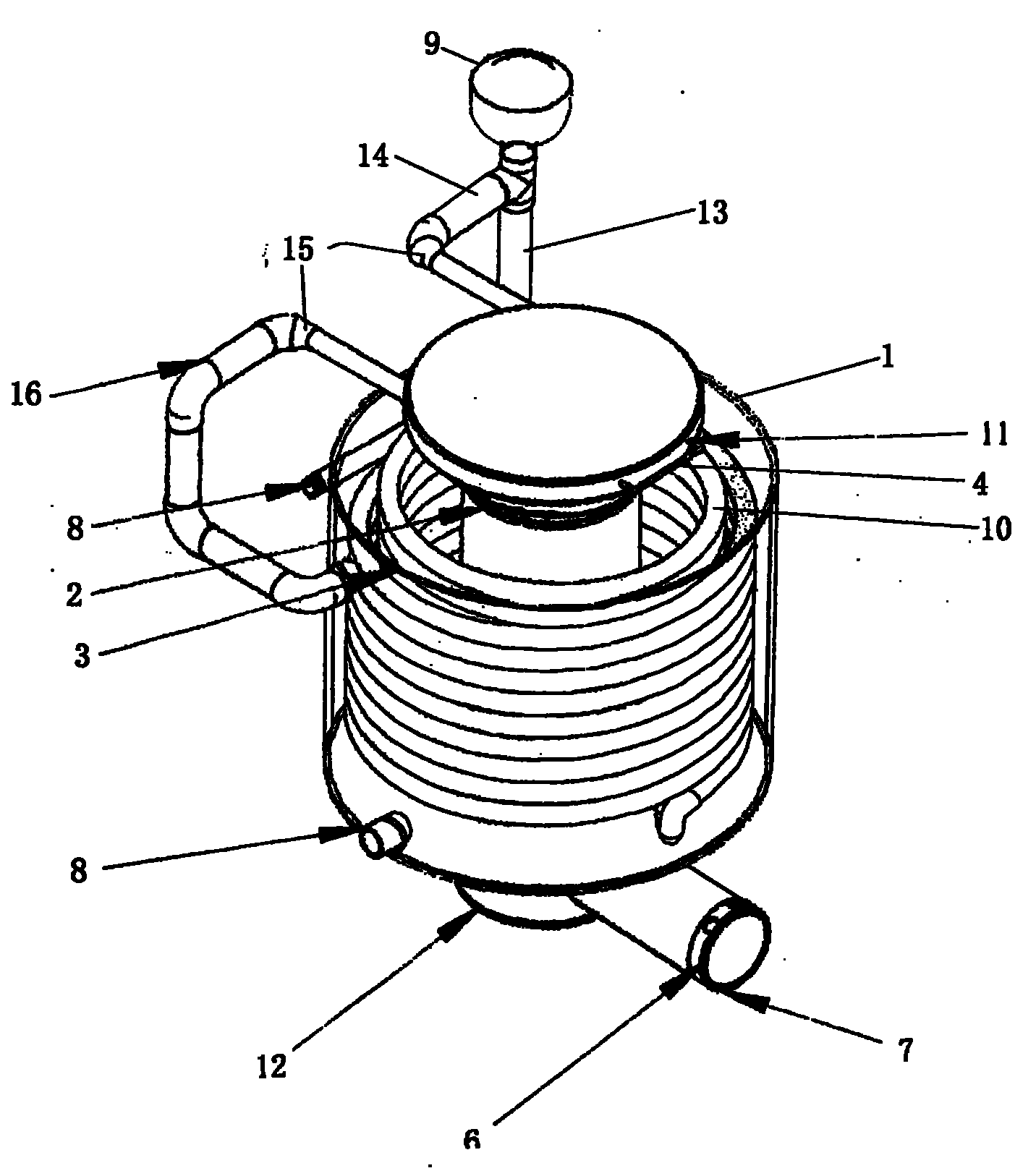

[0009] Safety stove of the present invention, see figure 1 , including furnace core 2, furnace body 3, coal can be burned in the furnace core, the furnace core wall is made of impermeable heat-conducting material, such as metal iron, etc., the furnace core can be set in the middle of the furnace body and supported by the furnace body, the furnace A water storage space is formed between the core 2 and the furnace wall 1 of the furnace body 3. Through the perspective of the furnace wall 1, it can be seen that there is an annular pipe 10 in the water storage space. The annular pipe is formed by a hollow heat conductor, and the interface 8 of the annular pipe extends out of the furnace body. It can be connected to the water inlet pipe and the water outlet pipe, wherein the water inlet pipe can be directly connected to the tap water pipe, and the water pressure of the tap water is used to make the water flow in the circular pipe, and the water outlet pipe can be connected to the fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com