Integrative bridge erection machine of shift type transporting and erecting girder and bridge erecting method

A bridge erecting machine and displacement technology, which is applied in bridge construction, erection/assembly of bridges, bridges, etc., to achieve the effect of reducing the working height and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

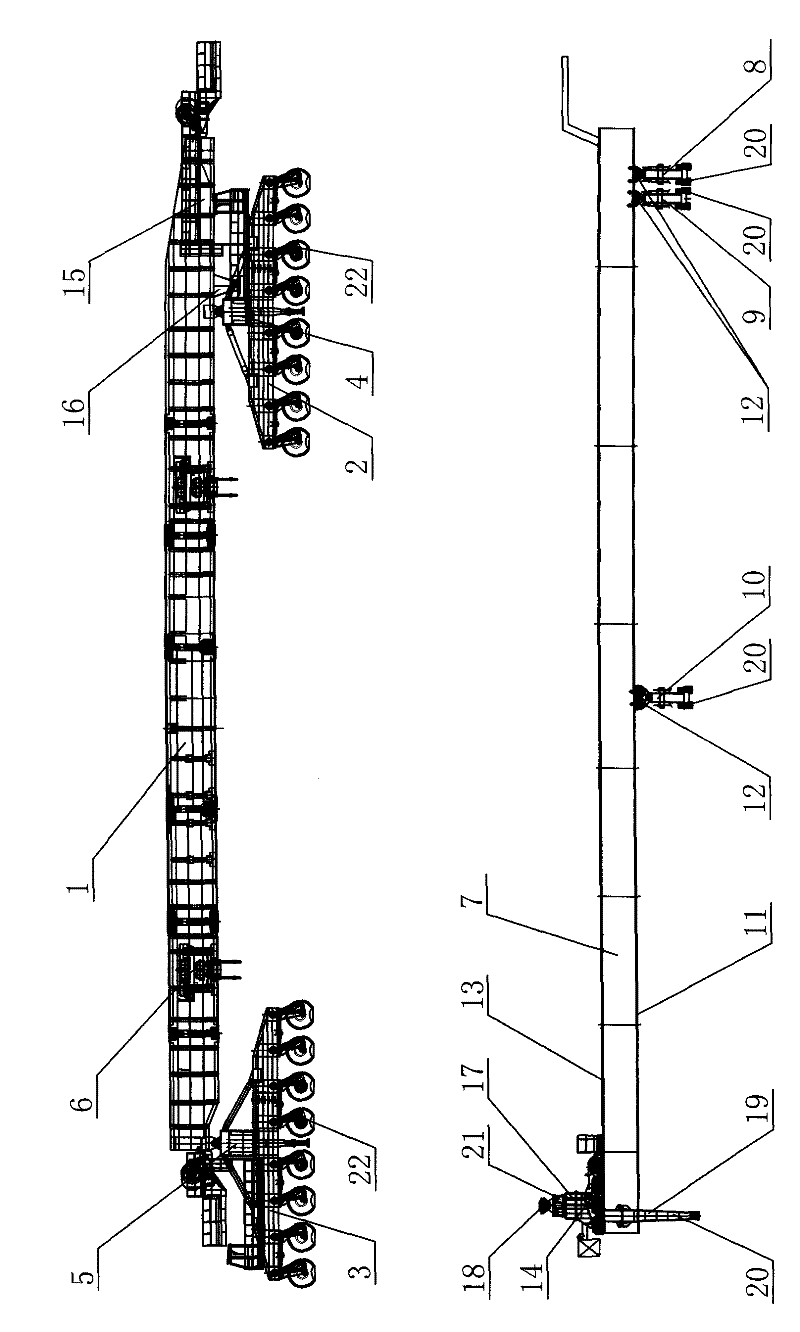

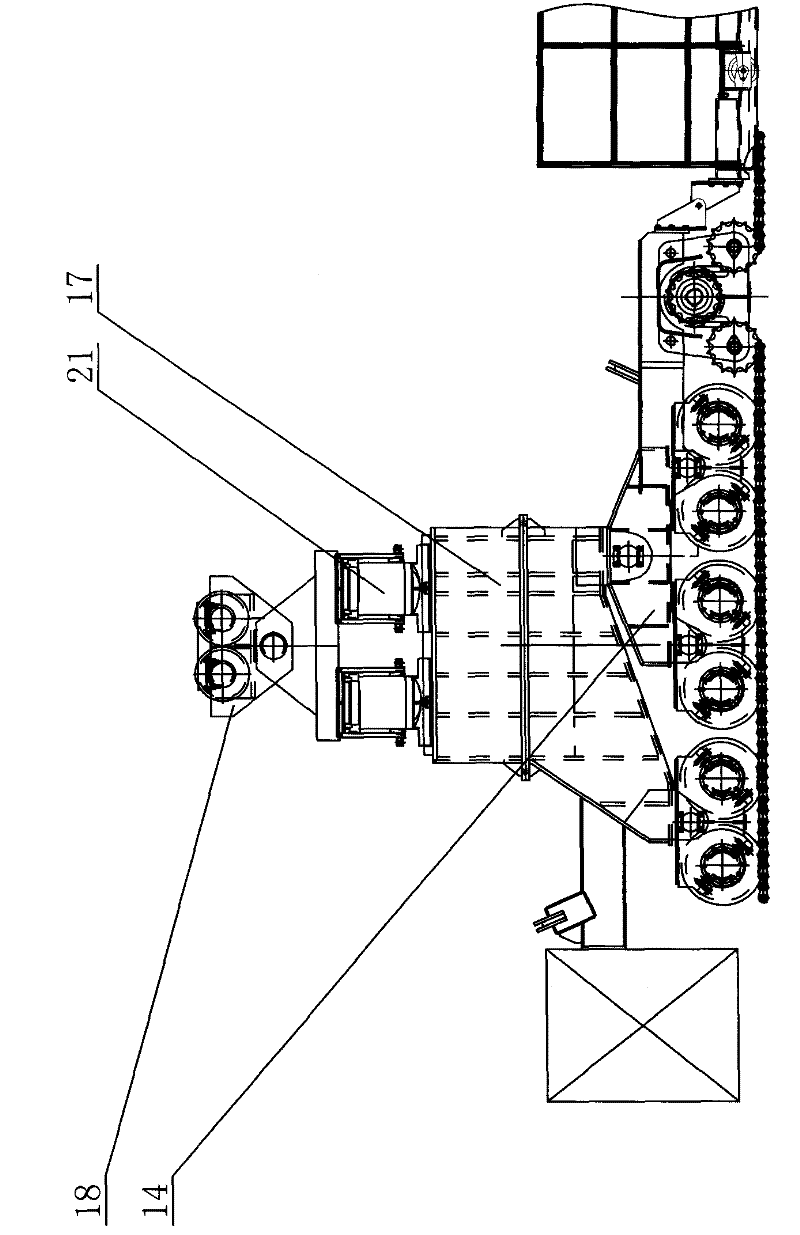

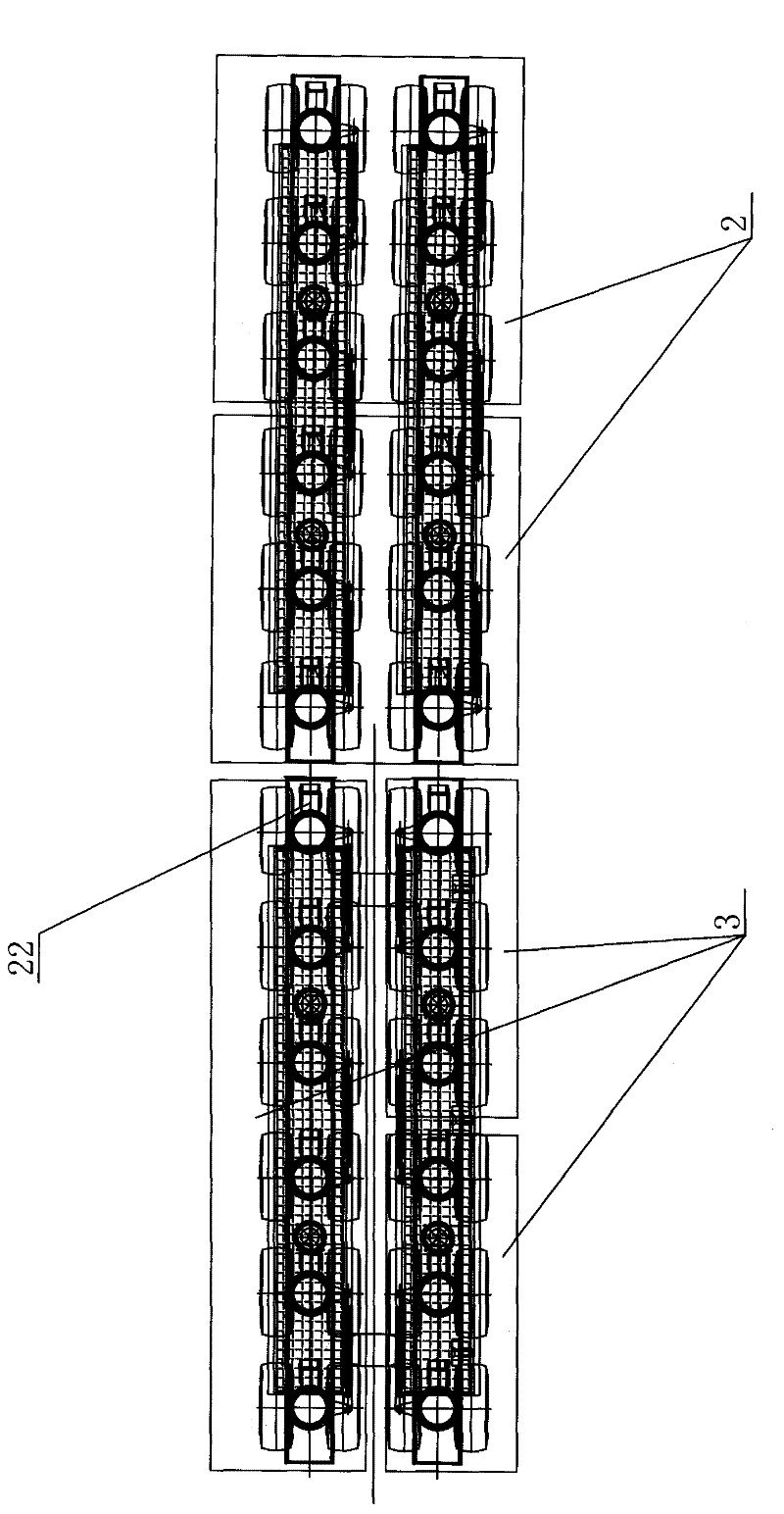

[0034] Such as figure 1 and figure 2 As shown, the displacement type girder integrated bridge erecting machine of the present invention includes a girder transporting machine and a lower guiding beam machine, and the girder transporting machine includes a main girder 1 and front and rear traveling wheel sets 2, 3, and the front and rear traveling wheels Each wheel pair of groups 2 and 3 is equipped with a balance oil cylinder 22, and the front and rear traveling wheel groups 2 and 3 are respectively equipped with front and rear support frames 4 and 5, and the front and rear support frames 4 and 5 are connected to the main beam 1. The two ends are hinged by pin shafts. A pair of lifting mechanisms 6 are installed on the main beam 1. The lower guide beam machine includes a guide beam 7, front, middle and rear roller legs 8, 9, and 10. The bottom of the guide beam 7 is equipped with a trolley guide rail 11. , the trolley guide rail 11 is provided with a small trolley 12, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com