Insulating method and device of oil pump motor stator of electric locomotive transformer powered up by frequency converter

A technology for electric locomotive and stator insulation, which is applied in laying solid insulation and other directions, can solve the problems of insulation continuity, poor integrity, poor motor operation reliability, and high dielectric loss, and achieve high resistance to high-frequency electrical breakdown and overall insulation. Good, low dielectric loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

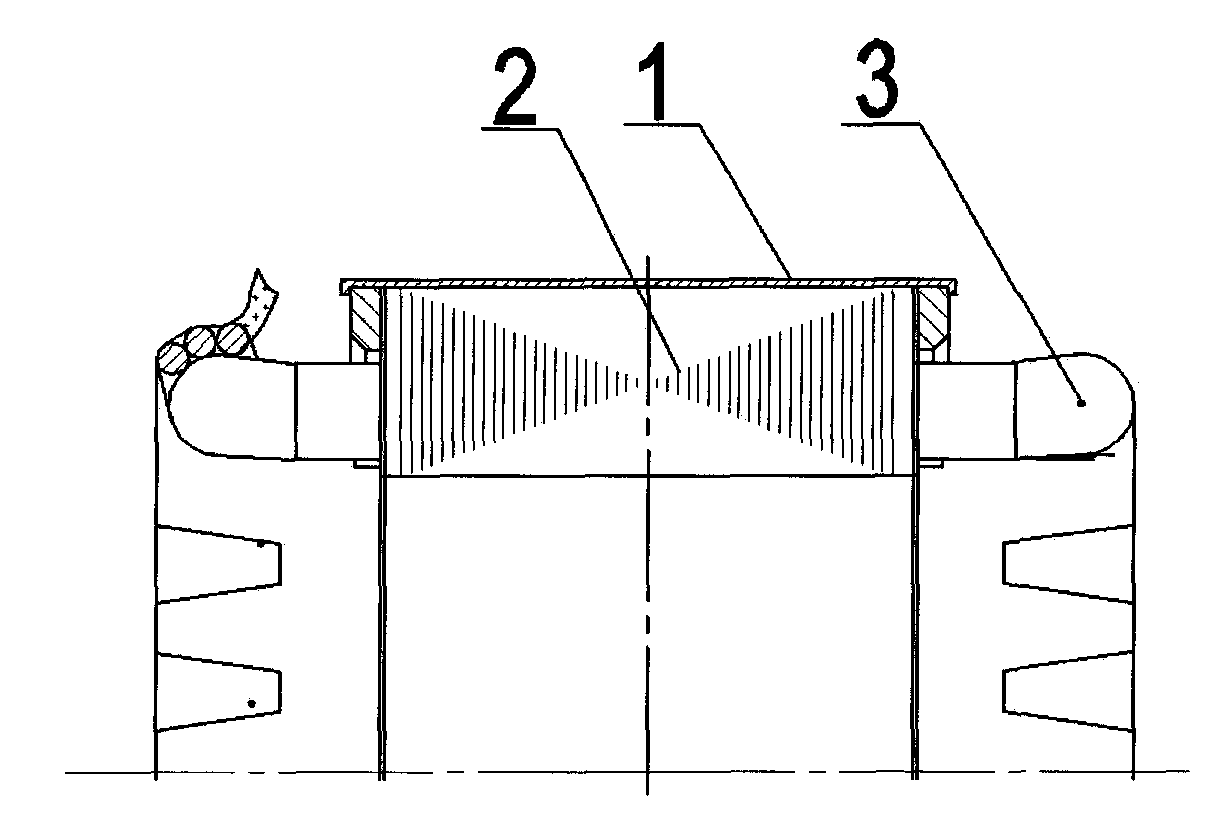

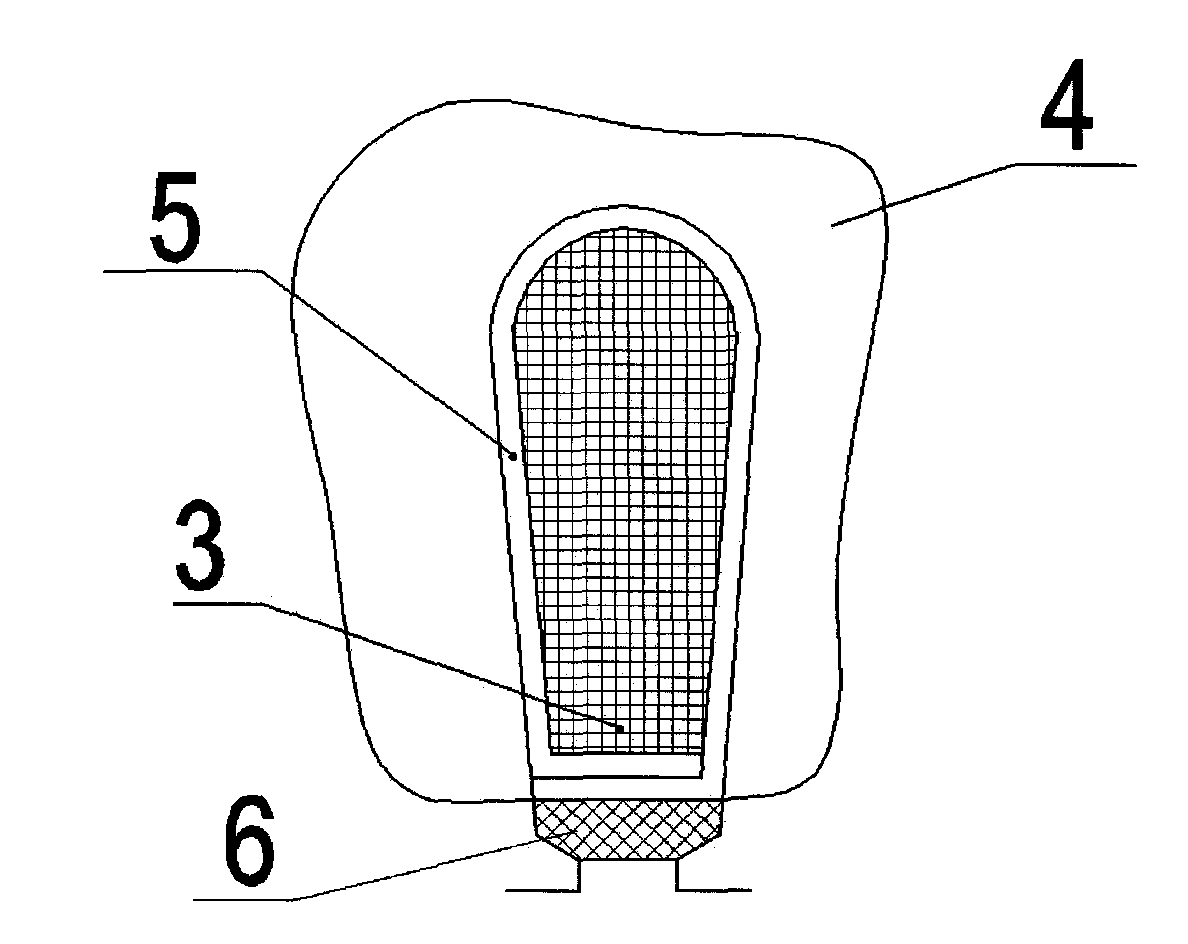

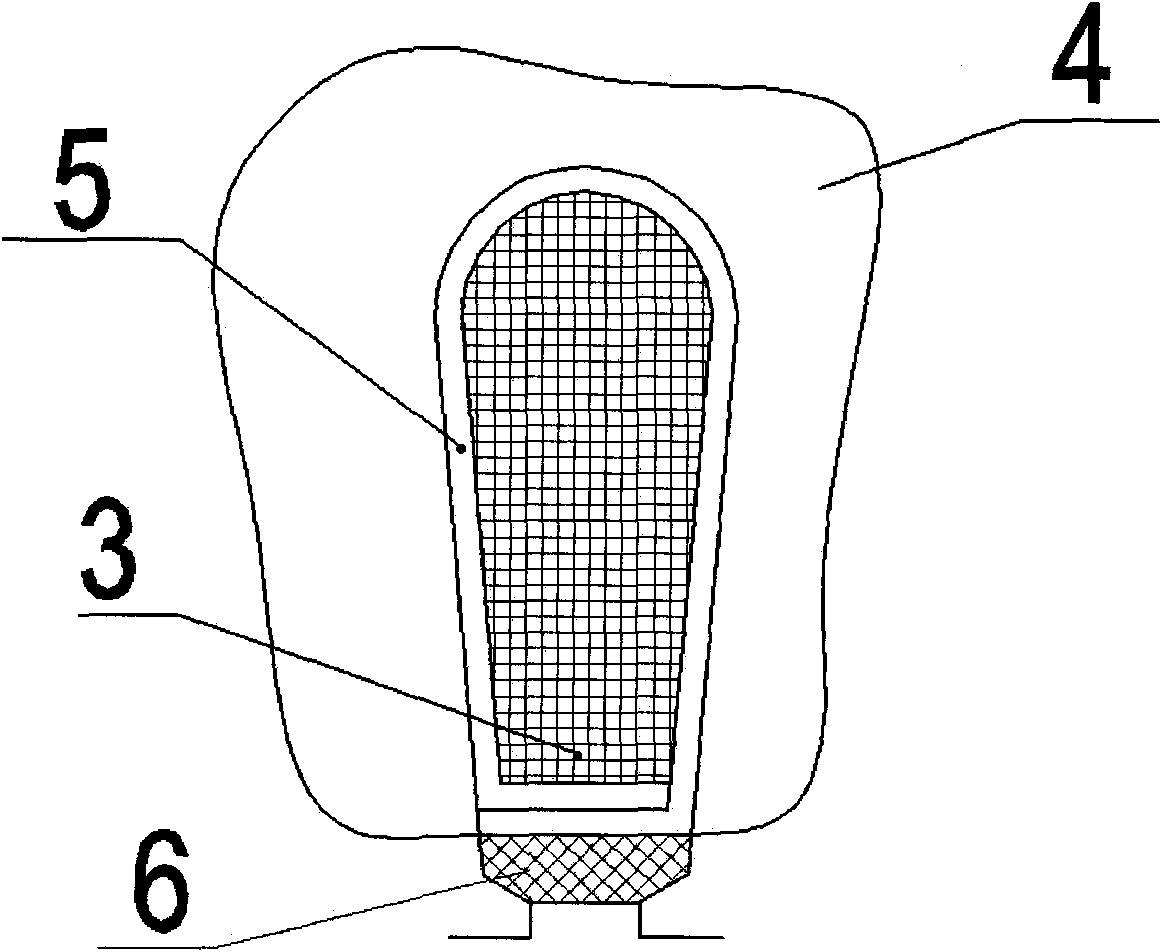

[0017] as attached Figure 1-2 As shown, the present invention is an insulation treatment method for the stator of an electric locomotive transformer oil pump motor powered by a frequency converter. The stator winding is made of an electromagnetic wire with a polyamide-imide hybrid nanomaterial insulation layer, and the stator adopts a scattered-embedded single-layer winding structure. , and then use NHN composite foil that can absorb corona-resistant solvent-free impregnating varnish for isolation and insulation treatment in the stator insulation slot and ground insulation, and then place the motor stator in a container with TJ1158H grade solvent-free impregnating varnish, and in The solvent-free impregnating varnish adds 3-5% of the total amount of the impregnating varnish to inorganic nanomaterials (such as alumina derivatives with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com