Levelling staff capable of adjusting observation position and measurement technique thereof

A technology of leveling ruler and craftsmanship, applied in the field of surveying, can solve the problems of high cost of observation piers, unsatisfactory observation accuracy, unreachable sight line of leveling instruments, etc., and achieves the effects of increasing labor cost, reducing overall observation cost, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

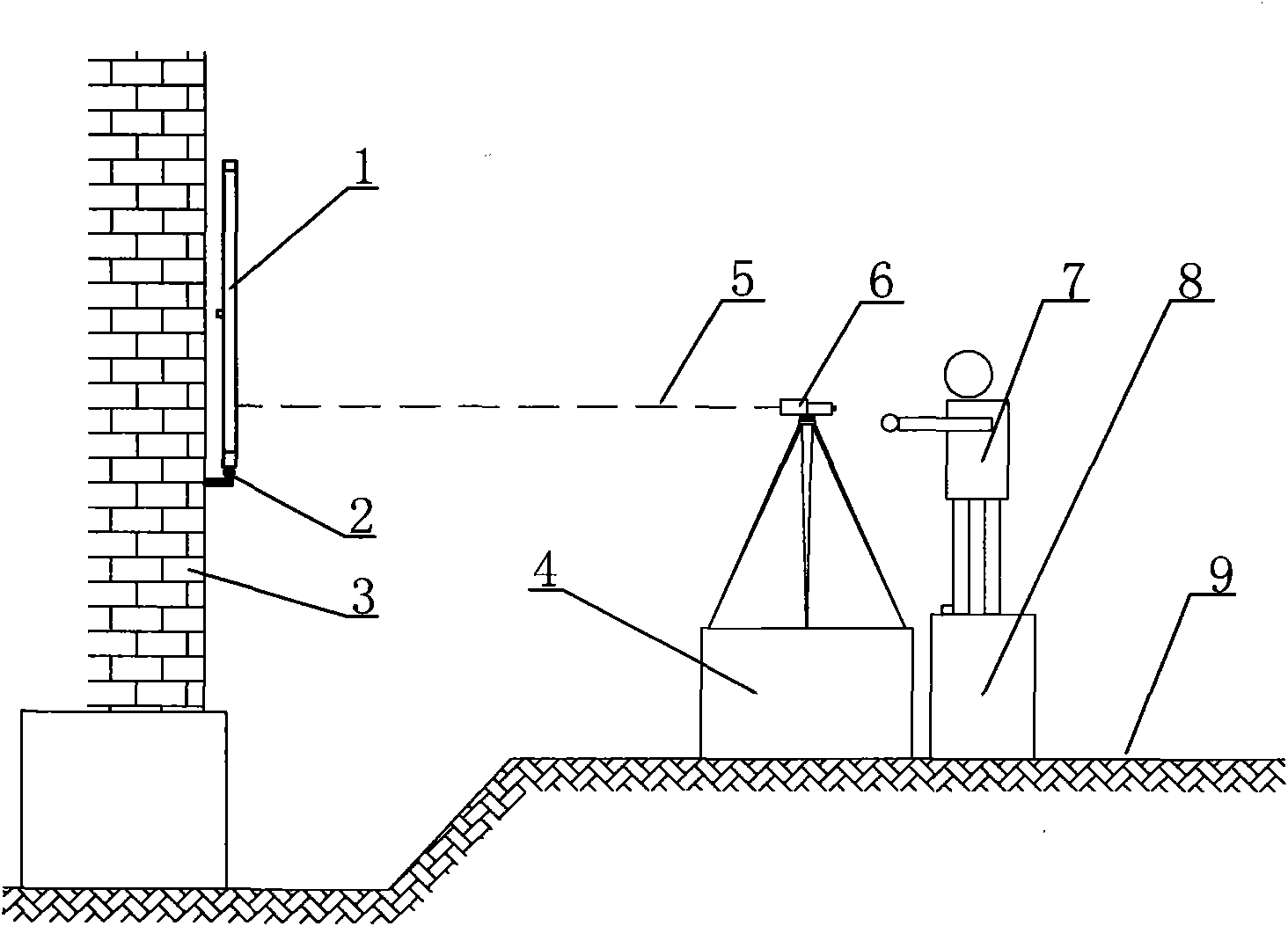

[0047] The present invention will be further explained below in conjunction with the accompanying drawings. It should be noted that the purpose of disclosing the present invention is to protect all changes and improvements of the present invention. As long as the technical scheme of changing and adjusting the position of the leveling rod through the auxiliary device is included in the scope of the present invention within the scope of protection.

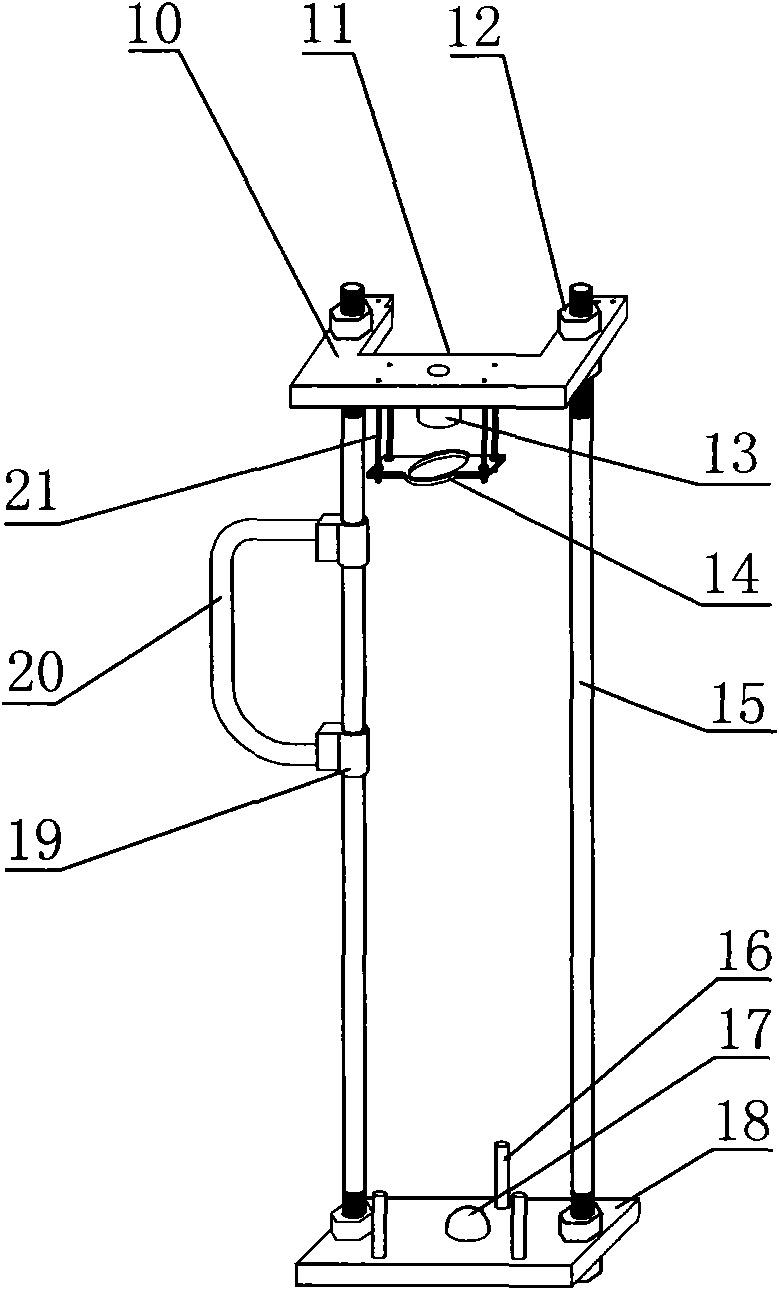

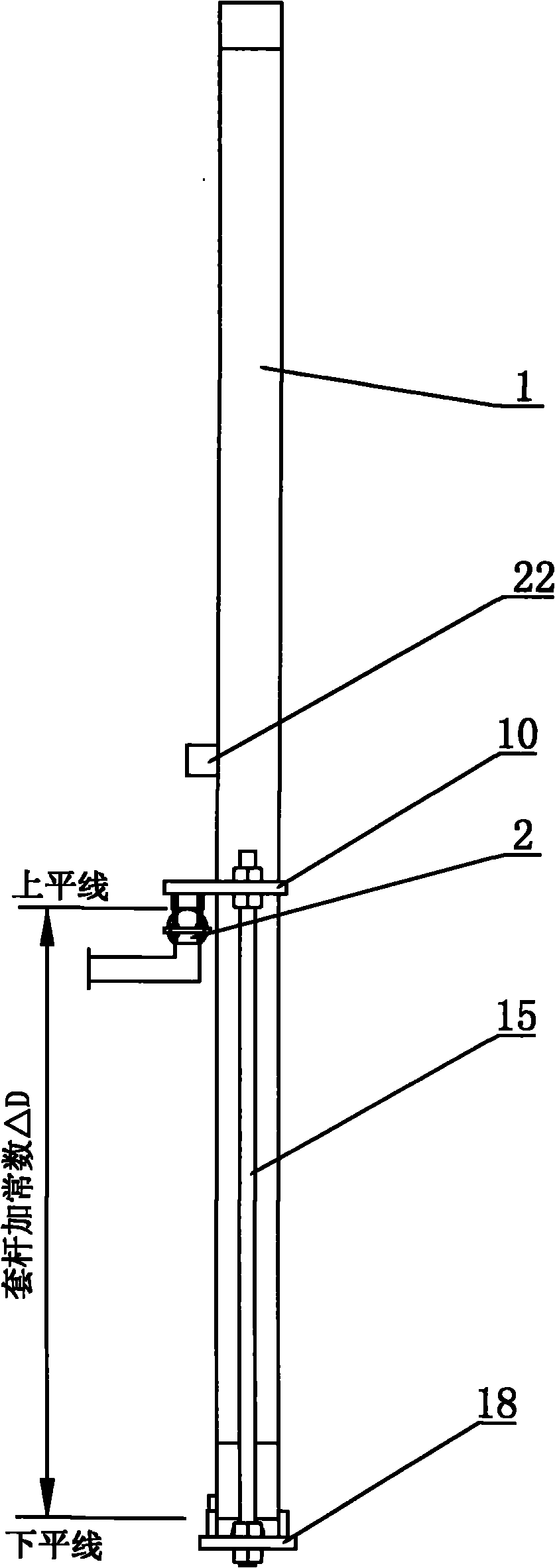

[0048] figure 2 Among them, the auxiliary sleeve includes an upper plate 10, a vertical rod 15, and a lower plate 18. The vertical rod 15 is a screw structure with threads at both ends. The nuts 12 on the top and bottom of the disc 10 and the lower disc 18 tighten the vertical rod 15, and the vertical relationship between the upper and lower discs and the vertical rod 15 can be adjusted by adjusting the screwing distance between the nut 12 and the vertical rod 15, and the distance between the upper and lower discs can be adjusted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com