Heat accumulating type combustion device with rotary valve capable of improving sealing during wind direction conversion process

A combustion device and wind direction conversion technology, applied in the combustion method, combustion type, air quality improvement and other directions, can solve problems such as poor maintenance and fixation, and achieve the effects of preventing environmental pollution, reducing consumption, and improving sealing treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the configuration and operation of the embodiments of the present invention will be described in detail with reference to the drawings, as follows. In addition, in describing the present invention, when it is judged that the specific description of related known functions or configurations may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

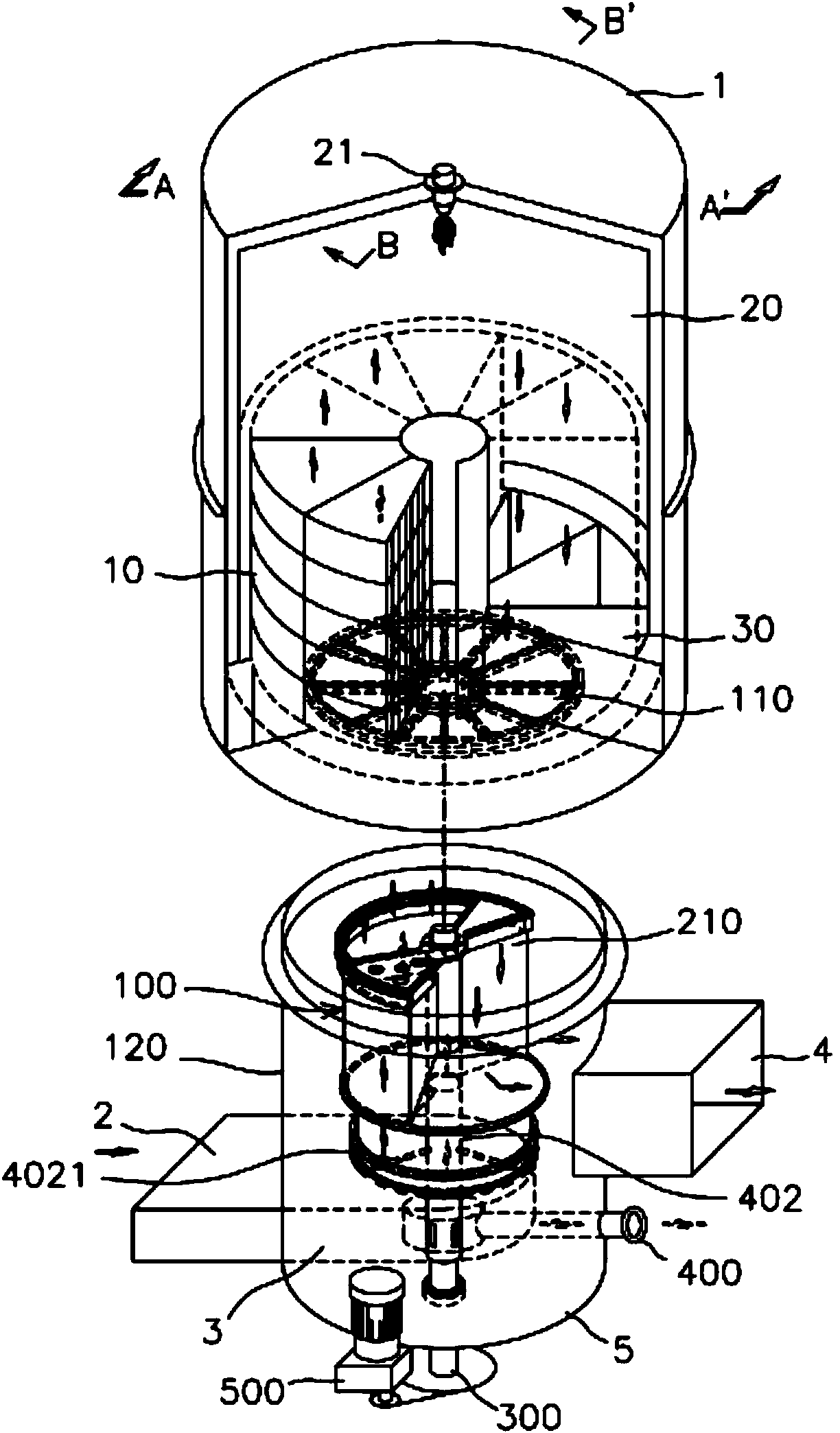

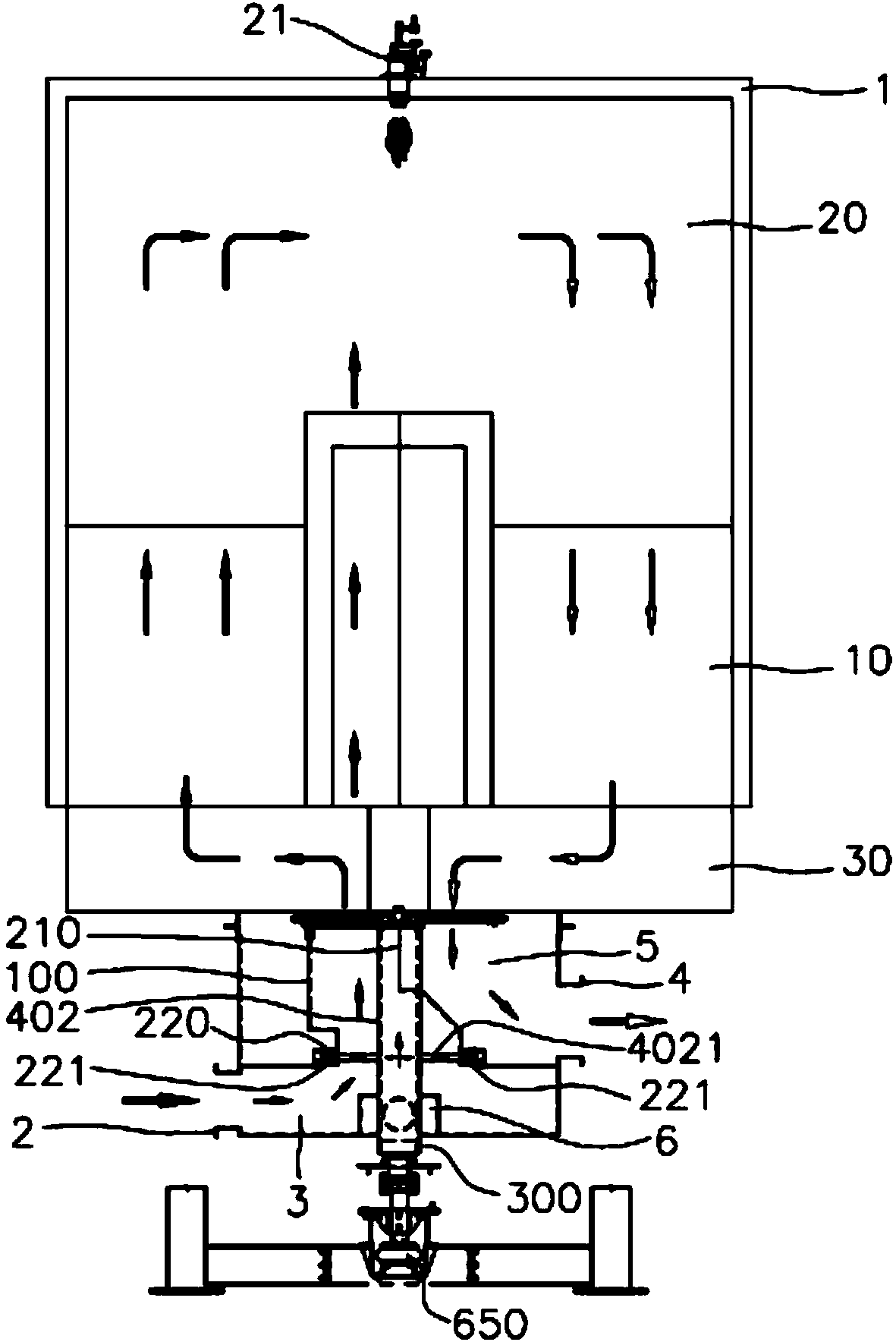

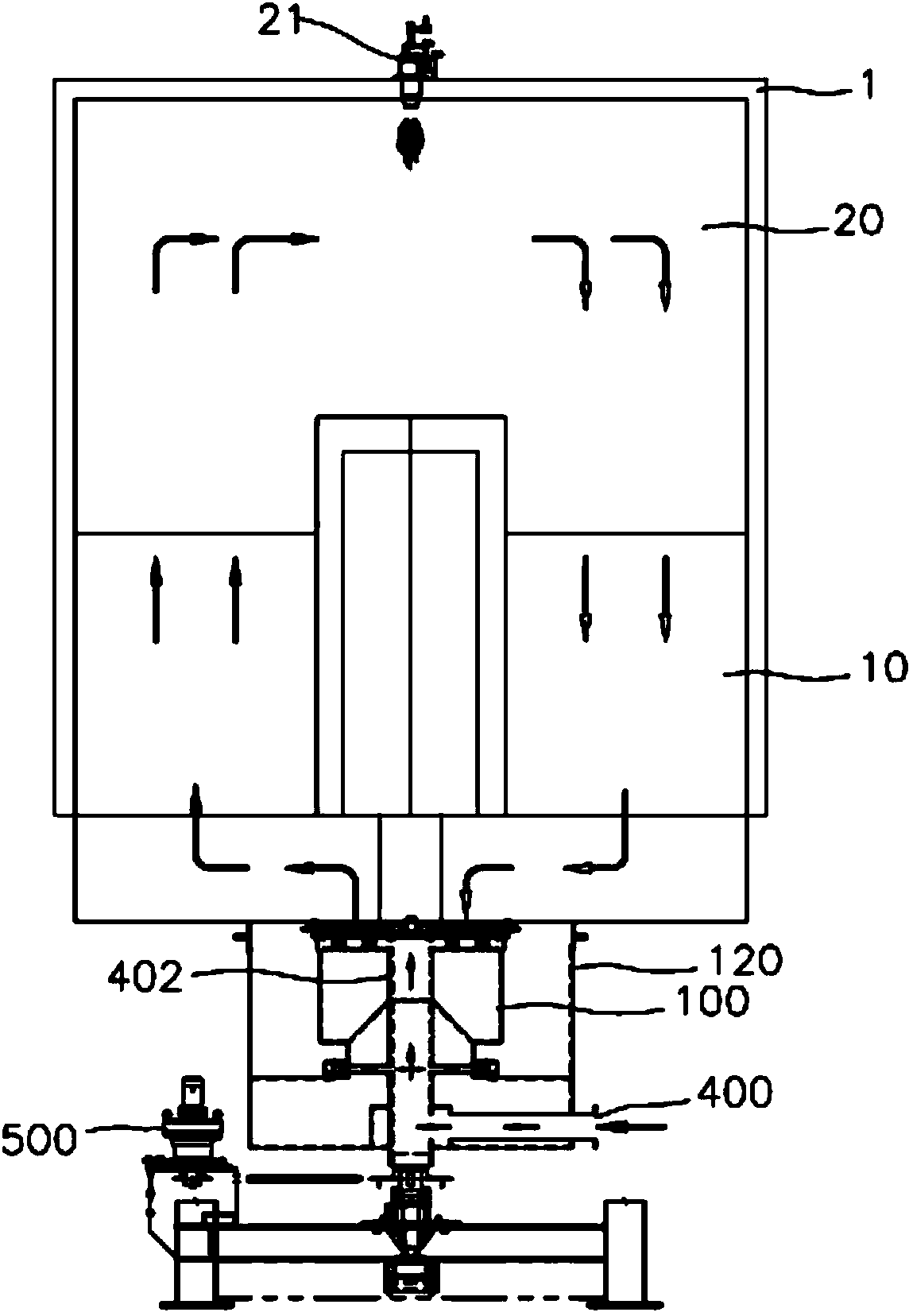

[0053] figure 1 is a perspective view showing a rotary valve installed in the lower part of the regenerative combustion equipment according to one embodiment of the present invention, figure 2 yes means figure 1 A cross-sectional view of the A-A' section, image 3 yes means figure 1 Cross-sectional view of the B-B' section.

[0054]As shown in the figure, the basic composition of the regenerative combustion device with a rotary valve according to the present invention includes: a combustion device 1, which includes a catalyst and a heat storage material layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com