Short-stroke synchronizer ring

A synchronous ring and short-stroke technology, which is applied in the direction of transmission parts, clutches, belts/chains/gears, etc., can solve the problems of increased working load of synchronous rings, increased wear of synchronous rings, increased frictional loads, etc., and achieves improved work permits Effects of pressure and rotation speed, volume and weight reduction, and axial size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

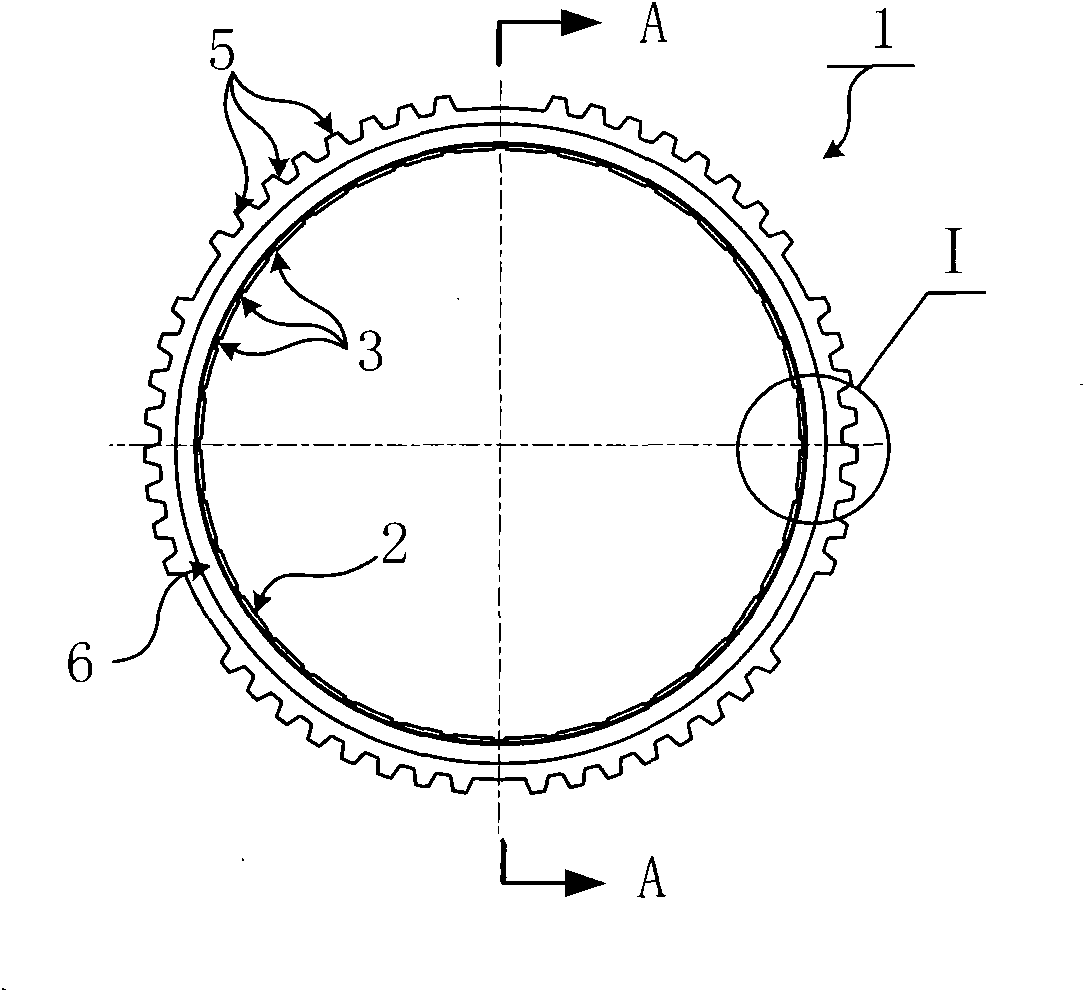

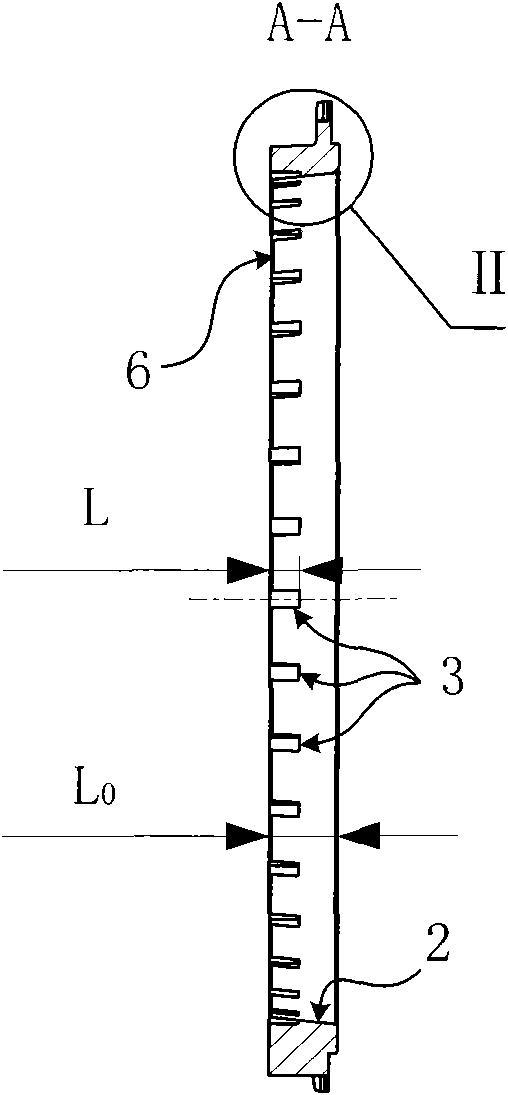

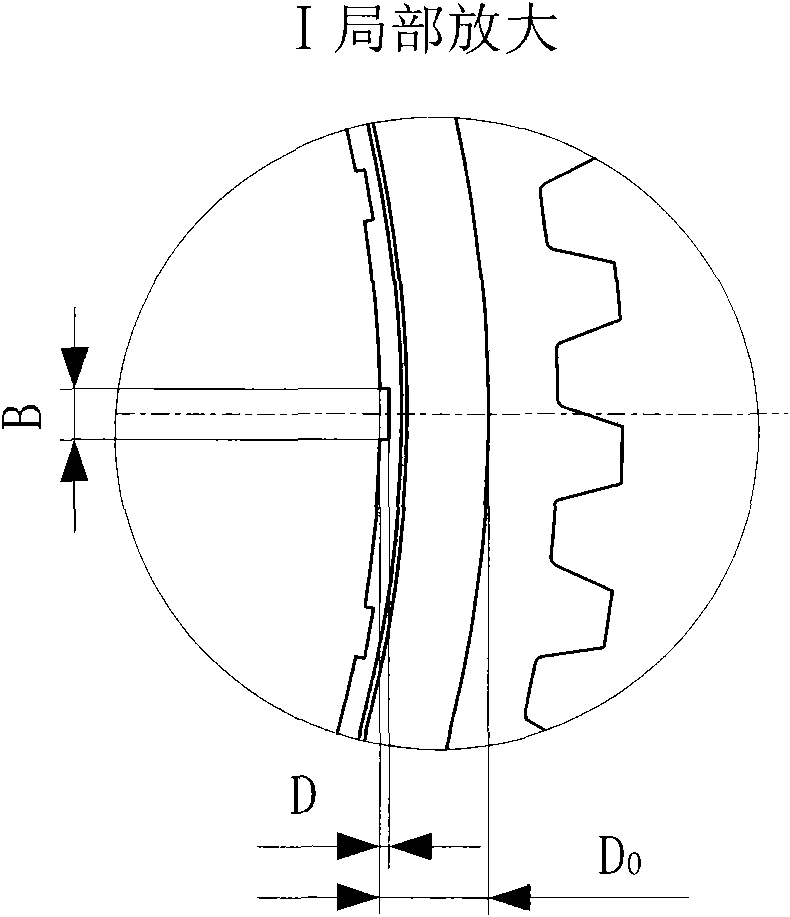

[0012] In order to make the synchronous ring meet different use requirements under different working conditions, the size and distribution of the rectangular groove of the synchronous ring have the following requirements: the length L of the rectangular groove is between the axial length L of the synchronous ring 0 Between 0.3 times and 0.5 times; the width B of the rectangular groove is between 2.5mm and 5mm; the depth D of all the rectangular grooves is equal, and the depth of each groove is constant, and the depth D of the rectangular groove is between the thickness of the synchronous ring D. 0 between 0.1 and 0.2 times; the distribution of rectangular grooves is evenly distributed in the circumferential direction, and the angle between the centerlines of two adjacent grooves is between 10° and 15°.

[0013] The rectangular groove is opened from the inner end face 6 of the synchronous ring, such as Figure 4 .

[0014] When the synchronous ring is in a non-working state, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com