Fiber mixing method and device

A blending and fiber technology, applied in fiber mixing, fiber treatment, textiles and papermaking, etc., can solve the problems of damaged fibers, process color difference, fiber spinnability decline, etc., to reduce power consumption, reduce fiber damage, The effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In this group of inventions, the initial carding mixer, the output fan and the fine cotton opener in the equipment can be completely implemented by corresponding equipment or devices in the prior art, and the main part of the air pressure control cotton box and the electrical control part can also completely adopt the existing There are corresponding equipment or devices in the art to realize.

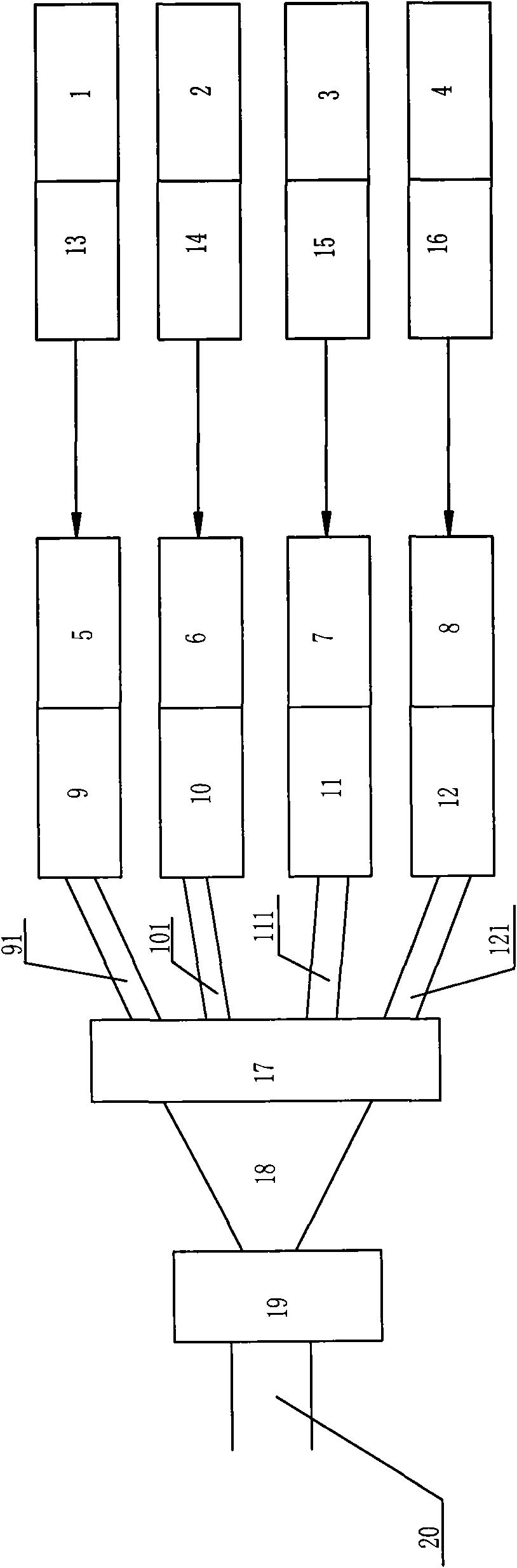

[0023] see figure 1 and figure 2 , the fiber mixing method in the present invention will be described below in conjunction with the fiber mixing equipment:

[0024]The invention relates to a fiber mixing equipment, which includes an initial carding and mixing unit, a conveying fan unit, an air pressure control box group, a fine cotton opening unit and a mixer. Taking the mixing of 4 different colors of fiber raw materials in the same raw material as an example, they are called the first fiber raw material, the second fiber raw material, the third fiber raw material and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com