Quasicrystal particle reinforced magnesium matrix composite material and preparation method thereof

A composite material and particle reinforcement technology, which is applied in the field of quasicrystal particle reinforced magnesium-based composite material and its preparation, Mg-Zn-Gd based thermally stable icosahedral quasicrystal-reinforced magnesium-based composite material, which can solve the problem of quasicrystal content Difficult to control, difficult to disperse evenly, high energy consumption, etc., to avoid different expansion coefficients, poor wettability, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Get 38 grams of pure Mg particles, 2 grams of quasicrystal particles Mg-Zn-Gd, that is, the weight ratio of the quasicrystal particle addition is 5%, and prepare as follows:

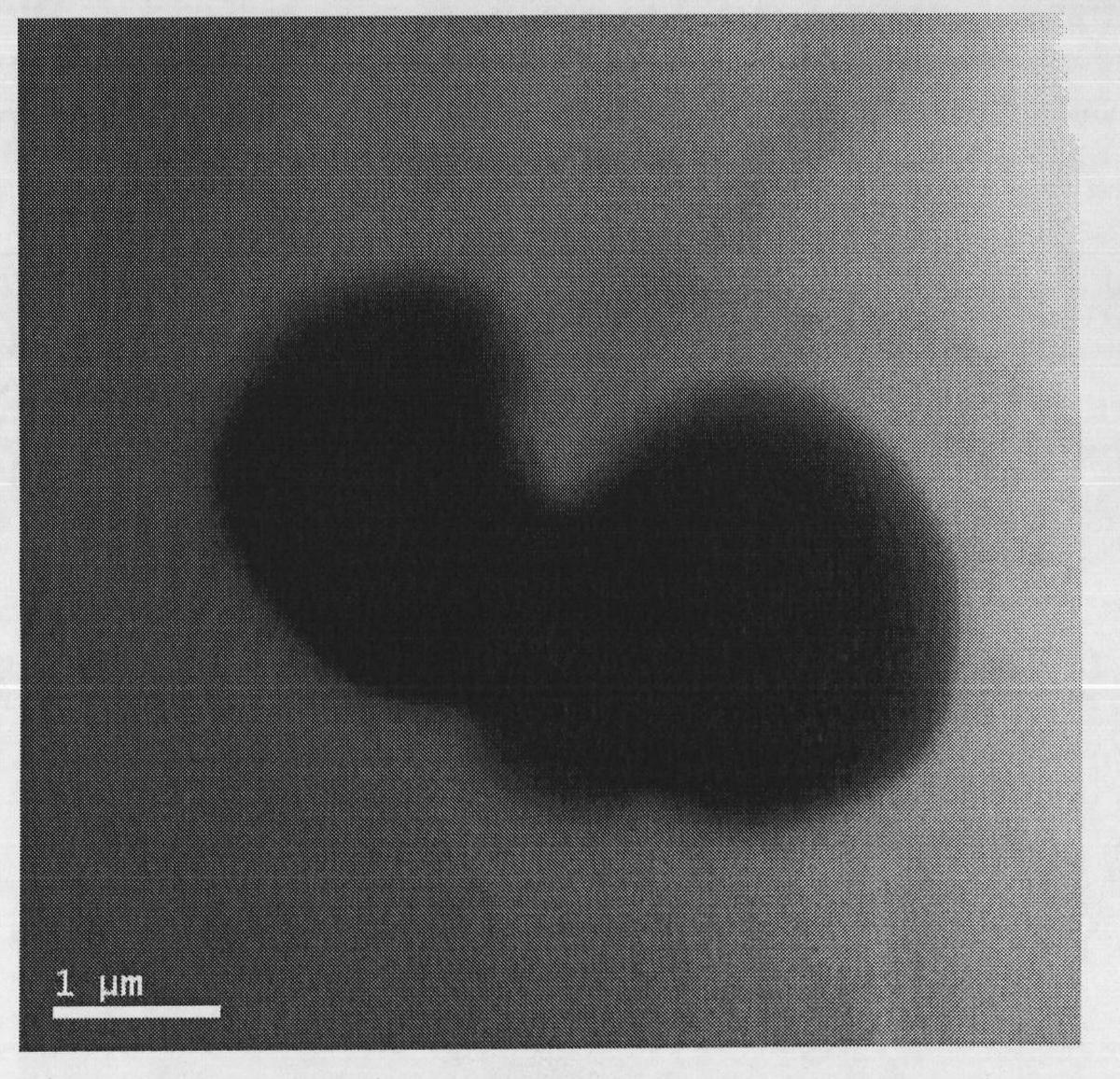

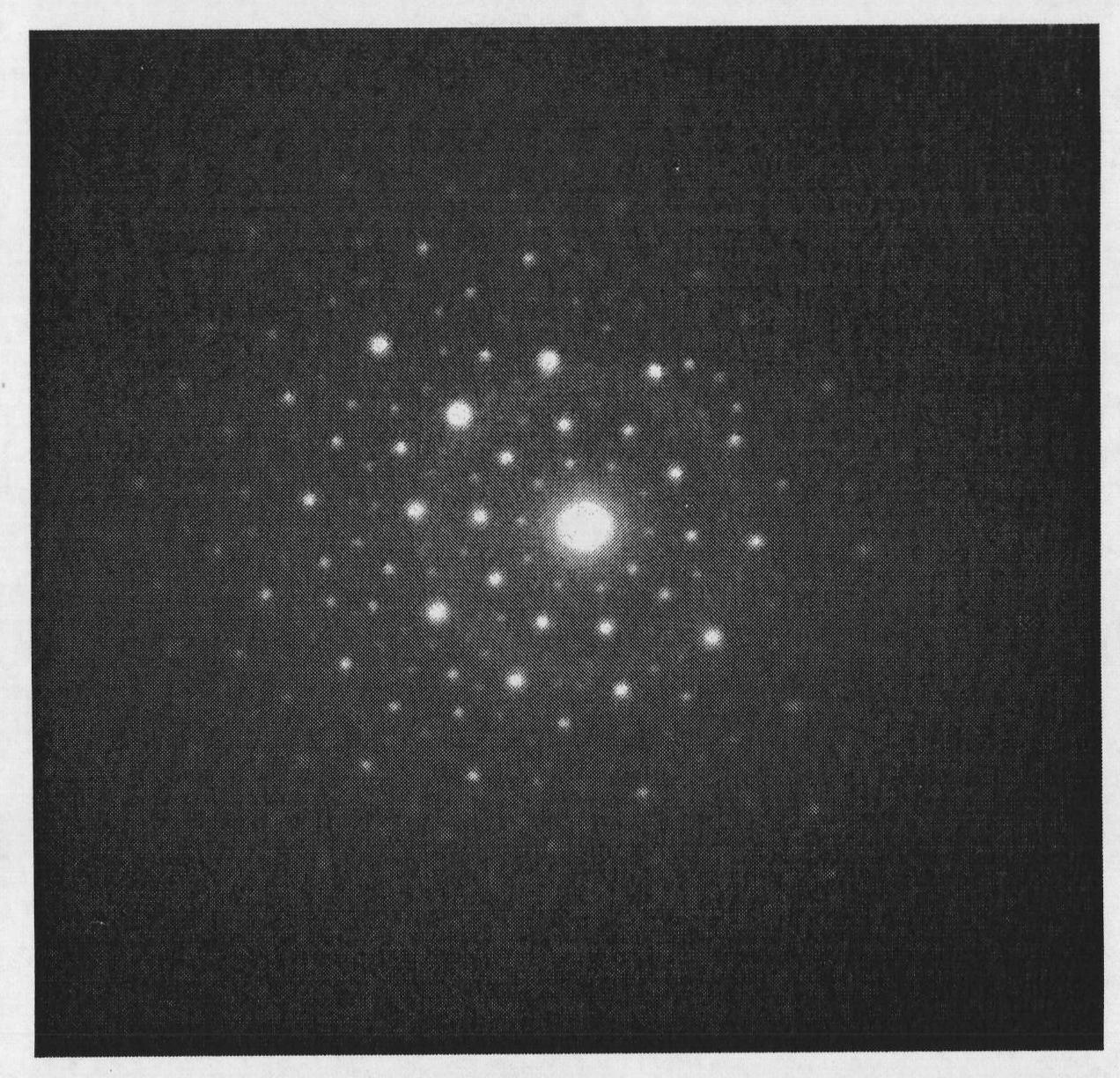

[0019] I. Prepare quasi-crystalline particles by ball milling, with a particle size of 20-100um;

[0020] II. Mix quasicrystalline particles and magnesium powder into the repeated plastic deformation equipment, and the number of deformations is selected to be 100 times;

[0021] III. The magnesium-based composite material obtained by repeated plastic deformation is extruded in a reverse extrusion die of 1:10, the extrusion temperature is 300 ° C, and the extrusion rate is 6 mm / min;

[0022] Tensile strength of the prepared composite profile: 268MPa; elongation after fracture: 9.7%

Embodiment 2

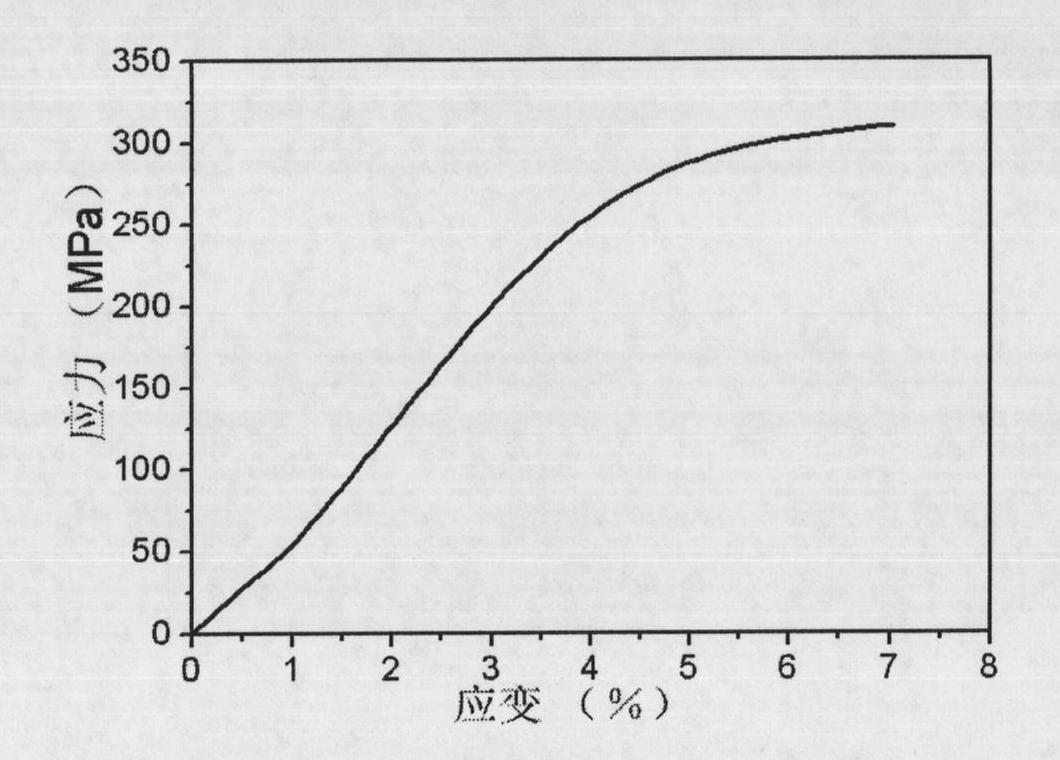

[0024] Get 36 grams of pure Mg particles, 4 grams of quasicrystal particles Mg-Zn-Gd, that is, the weight ratio of the quasicrystal particle addition is 10%, and it is prepared as follows:

[0025] I. Prepare quasi-crystalline particles by ball milling, with a particle size of 20-100um;

[0026] II. Mix quasicrystalline particles and magnesium powder into repeated plastic deformation equipment, and select 200 times of deformation times;

[0027] III. The magnesium-based composite material obtained by repeated plastic deformation is extruded in a reverse extrusion die of 1:16, the extrusion temperature is 360 ° C, and the extrusion rate is 6mm / min;

[0028] Tensile strength of the prepared composite profile: 309MPa; elongation after fracture: 7.0%

Embodiment 3

[0030] Get 34 grams of pure Mg particles, 6 grams of quasicrystal particles Mg-Zn-Gd, that is, the weight ratio of the quasicrystal particle addition is 15%, prepared as follows:

[0031] I. Prepare quasicrystalline particles by ball milling, with a size of 20-100um;

[0032] II. Mix quasicrystalline particles and magnesium powder into repeated plastic deformation equipment, and select 200 times of deformation times;

[0033] III. The magnesium-based composite material obtained by repeated plastic deformation is extruded in a reverse extrusion die of 1:25, the extrusion temperature is 320 ° C, and the extrusion rate is 6 mm / min;

[0034] Tensile strength of the prepared composite profile: 292MPa; elongation after fracture: 5.4%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com