Sludge reduction and denitrification combined urban sewage and sludge combined treatment system

A technology for sludge reduction, nitrification and denitrification, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. problems, to reduce the content of COD and N, ease the load impact, and achieve the effect of efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

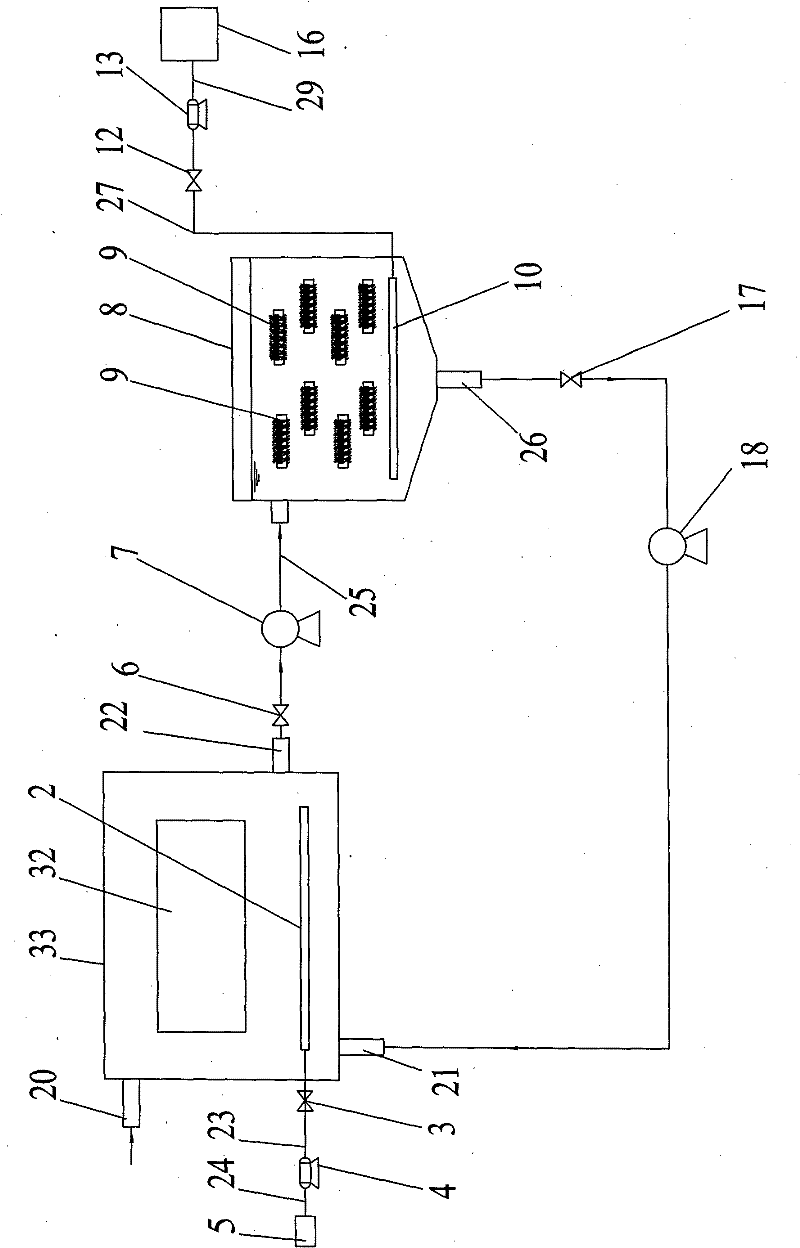

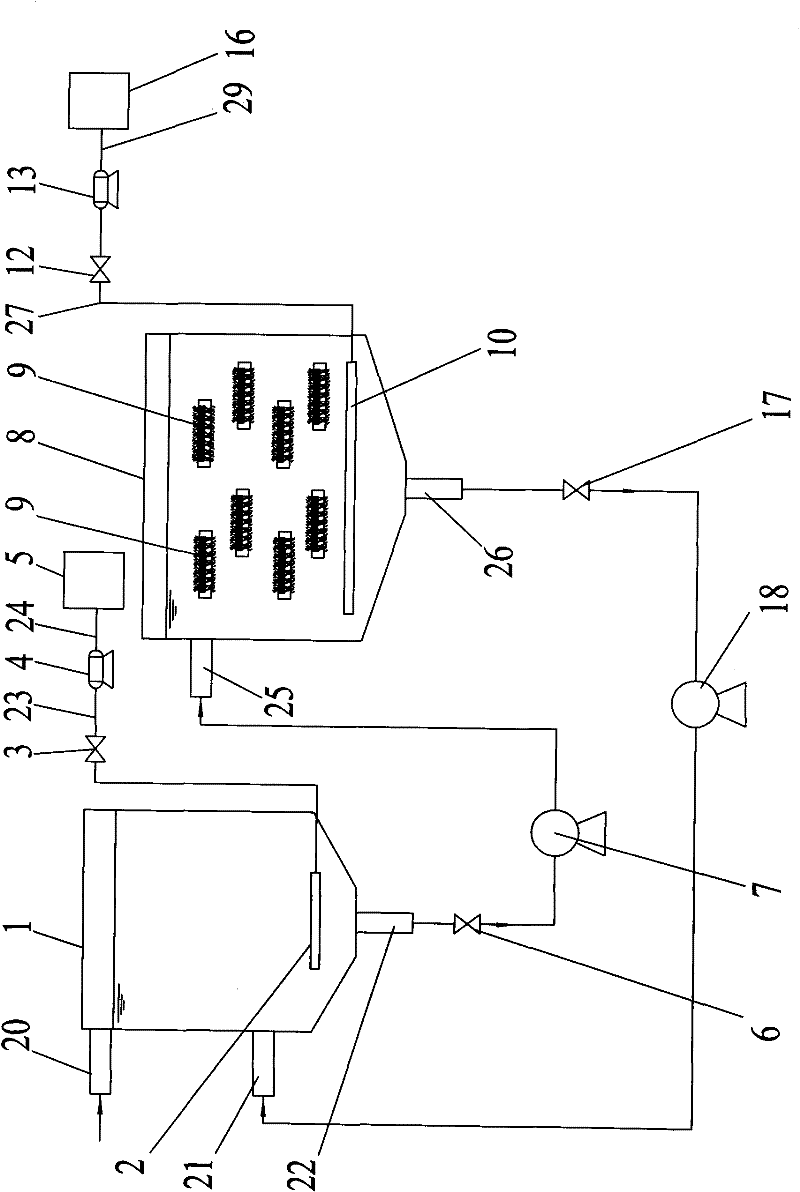

[0027] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, the urban sewage sludge combined treatment system of sludge reduction and denitrification denitrification coupling of this embodiment is composed of sequencing batch type biological sewage treatment device, first sludge discharge pump 7, fourth regulating valve 6, sewage It consists of a mud reduction device, a third regulating valve 17 and a second mud discharge pump 18;

[0028] The sequence batch biological sewage treatment device is composed of sequence batch bioreactor 1, water inlet pipe 20, first mud inlet pipe 21, first mud discharge pipe 22 and first aeration equipment; the first aeration equipment consists of the first An aerator head 2, a first air intake pipe 23, a first regulating valve 3, a first air compressor 4, a first time relay 5 and a first wire 24;

[0029] The sludge reduction device is composed of a sludge reduction reactor 8, a plurality of benthic biological ...

specific Embodiment approach 2

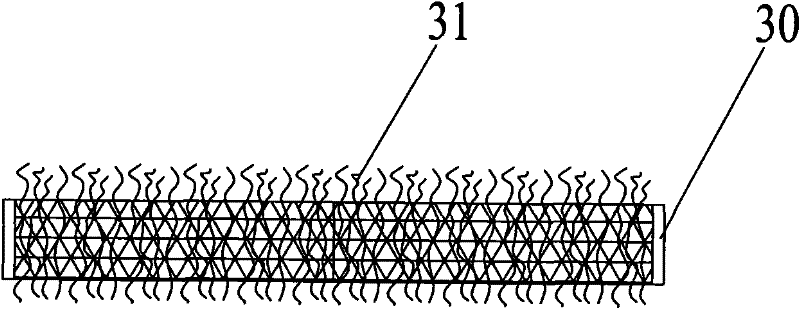

[0035] Specific implementation mode two: combination Figure 2-Figure 4 Describe this embodiment, the main body 30 of the attachment plate of this embodiment is a rectangular plate, the ratio of the length and width of the rectangular plate is 5:3, the thickness is 1-2cm, and there are a plurality of square holes 30-1 on the rectangular plate, each Each side hole wall of each square hole 30-1 is provided with a groove 30-2, and the groove 30-2 on each side hole wall of each square hole 30-1 jointly forms a back-shaped fixing groove, so The filler 31 is fixed on the main body 30 of the attachment plate through a zigzag fixing groove. Such setting has the characteristics of high air permeability, tightness, and large specific surface area, which is conducive to the high-density growth of benthic organisms. Other compositions and connections are the same as in the first embodiment.

[0036] Specific implementation mode three: combination Figure 4 The present embodiment will b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com