Double-blade boring cutter head without radial motion for cutter bar

A technology of radial movement and boring tool, applied in the direction of tool holder, etc., to achieve the effect of high efficiency, enhanced stability and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

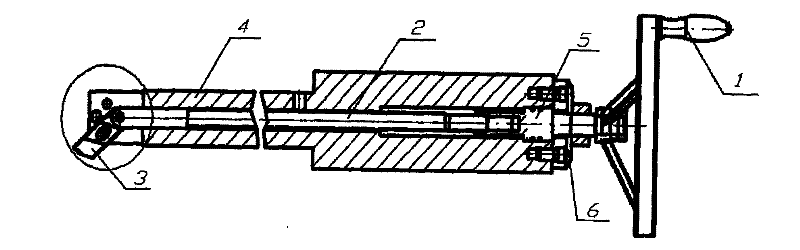

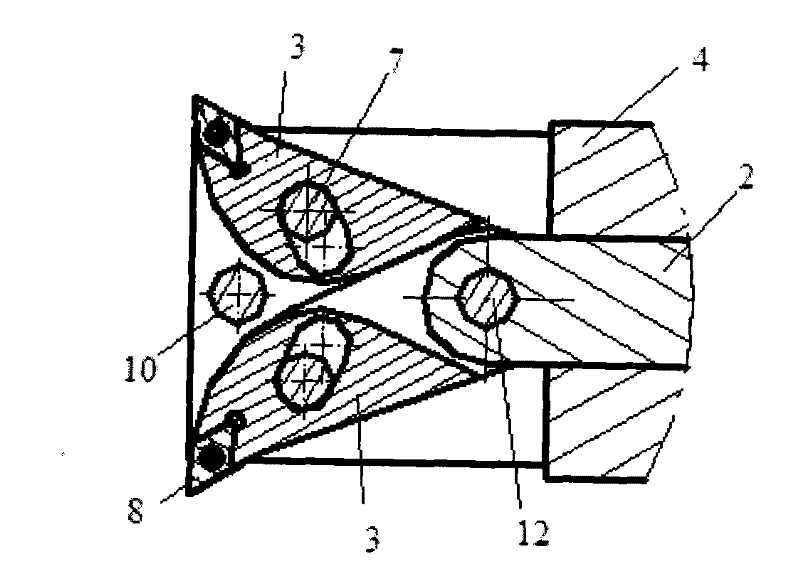

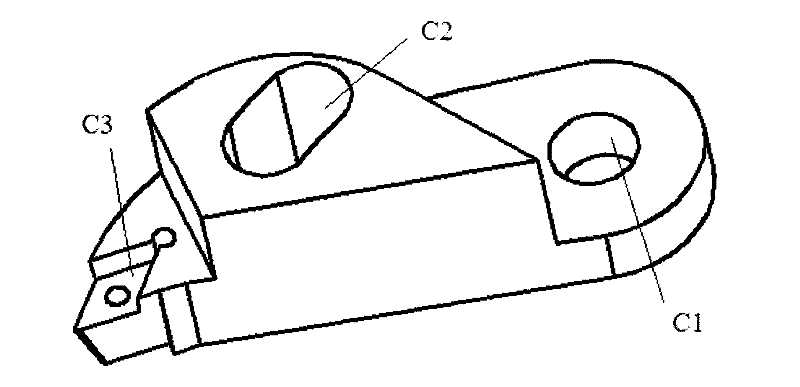

[0014] exist figure 1 In the embodiment of the telescopic double-edged deep hole boring tool described, the central axis of the boring bar (4) is formed with a through hole passing through the axis, and a pusher for connecting the radial feed mechanism of the bar head of the boring bar (4) is installed in the through hole. The rod (2) is provided with a rotary handle (1) at its rear end. The rotary handle (1) rotates the screw rod (5) to push the push rod (2) to perform axial telescopic movement in the through hole of the boring bar. The push rod (2) drives the tool holder (3) connected thereon with the movement mode of pulling or pushing, and the cutter holder (3) is connected with the push rod (2) by a rotating pin (12) rotating pair. The guide chute (C2) on the tool seat (3) is linked with the fixing screw (7) to move the pair. When the push rod (2) is pulled or pushed, the tool seat (3) moves along the direction along its guide chute (C2) chute under the action of a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com