Branch grinder

A shredder and branch technology, applied in grain processing and other directions, can solve the problems of affecting the service life of the blade, incomplete shredding of branches, easy clogging of chips, etc., to achieve relatively low cost, complete shredding of branches, and sufficient chip evacuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

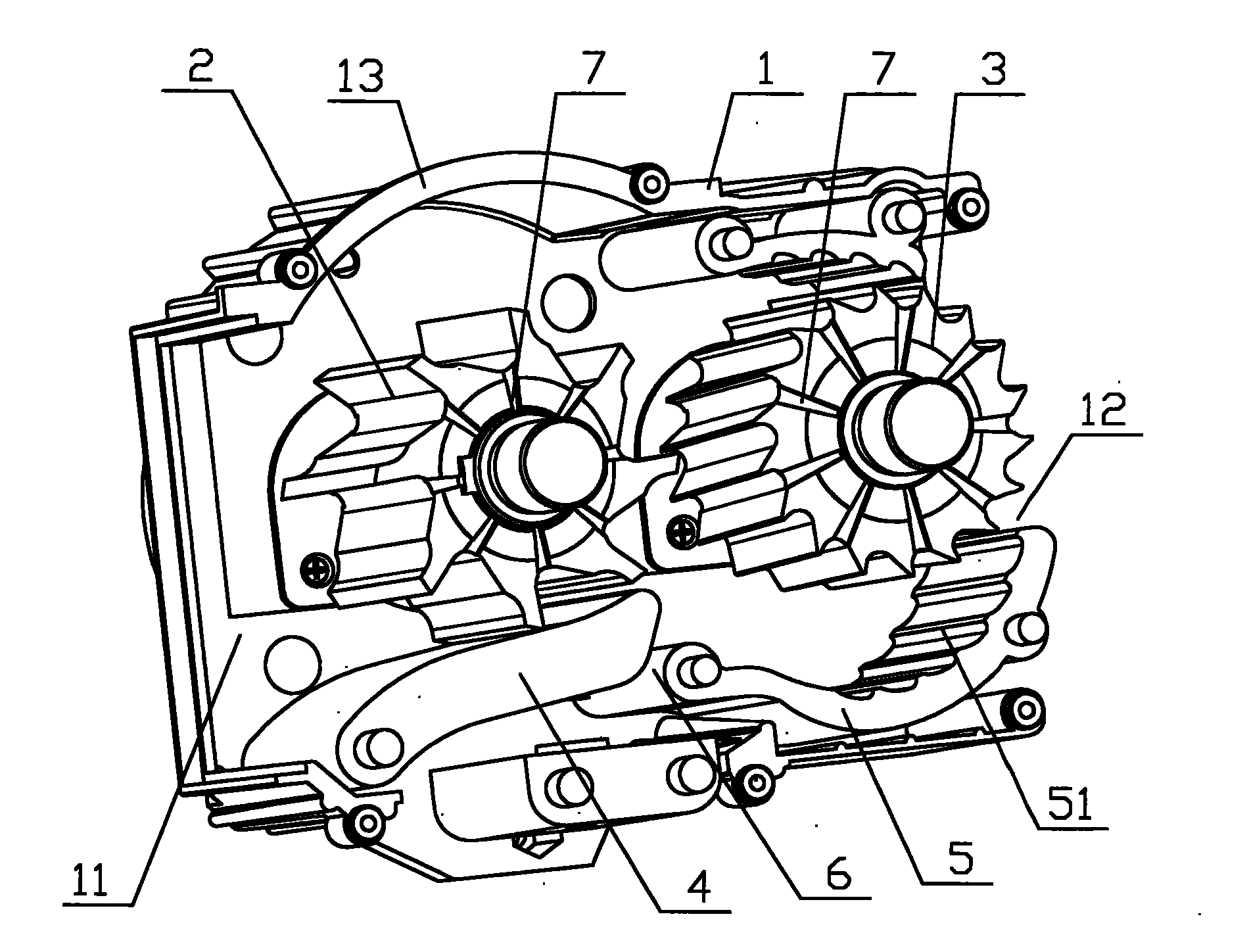

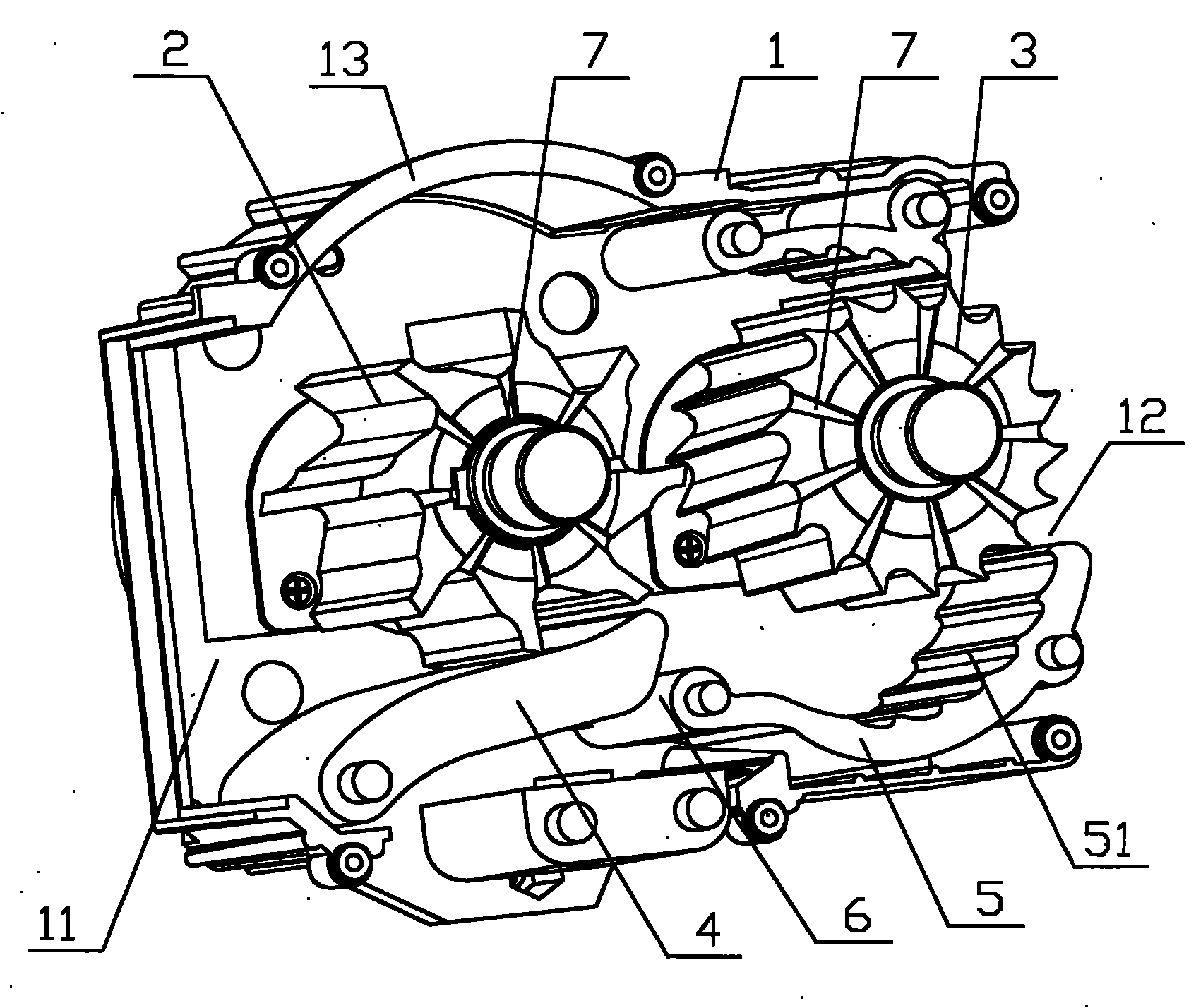

[0017] Such as figure 1 As shown, a tree branch crusher includes a housing 1 and a hob assembly. One end of the housing is provided with a material inlet 11, and the other end is provided with a material outlet 12. The first-stage hob 2 on the side of the mouth and the second-stage hob 3 on the side of the discharge port are provided with a guide plate 4 below the first-stage hob on the housing, and a Arc-shaped space 13, an arc-shaped guide plate 2 5 is provided on the housing below the second-stage hob, the first-stage hob and the second-stage hob rotate in the same direction, which is shown as counterclockwise in the figure of this embodiment direction. The first-level hob is close to the second-level hob, the distance between the first-level hob and the second-level hob is 1-6 cm, and there is at least one hob blade between the first-level hob and the second-level hob It is an oblique blade, and the blade of the secondary hob is an oblique blade in the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com