Split-type squeeze roller assembly structure and assembly method

A technology of assembling structure and squeezing roller, which is applied in metal processing, grain processing, metal processing equipment and other directions, can solve the problems of shortening the service life of the roller sleeve, frequent replacement cycles, shortening the service life of the squeezing roller, etc., so as to improve the service life. , The effect of shortening the assembly cycle and reducing the cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

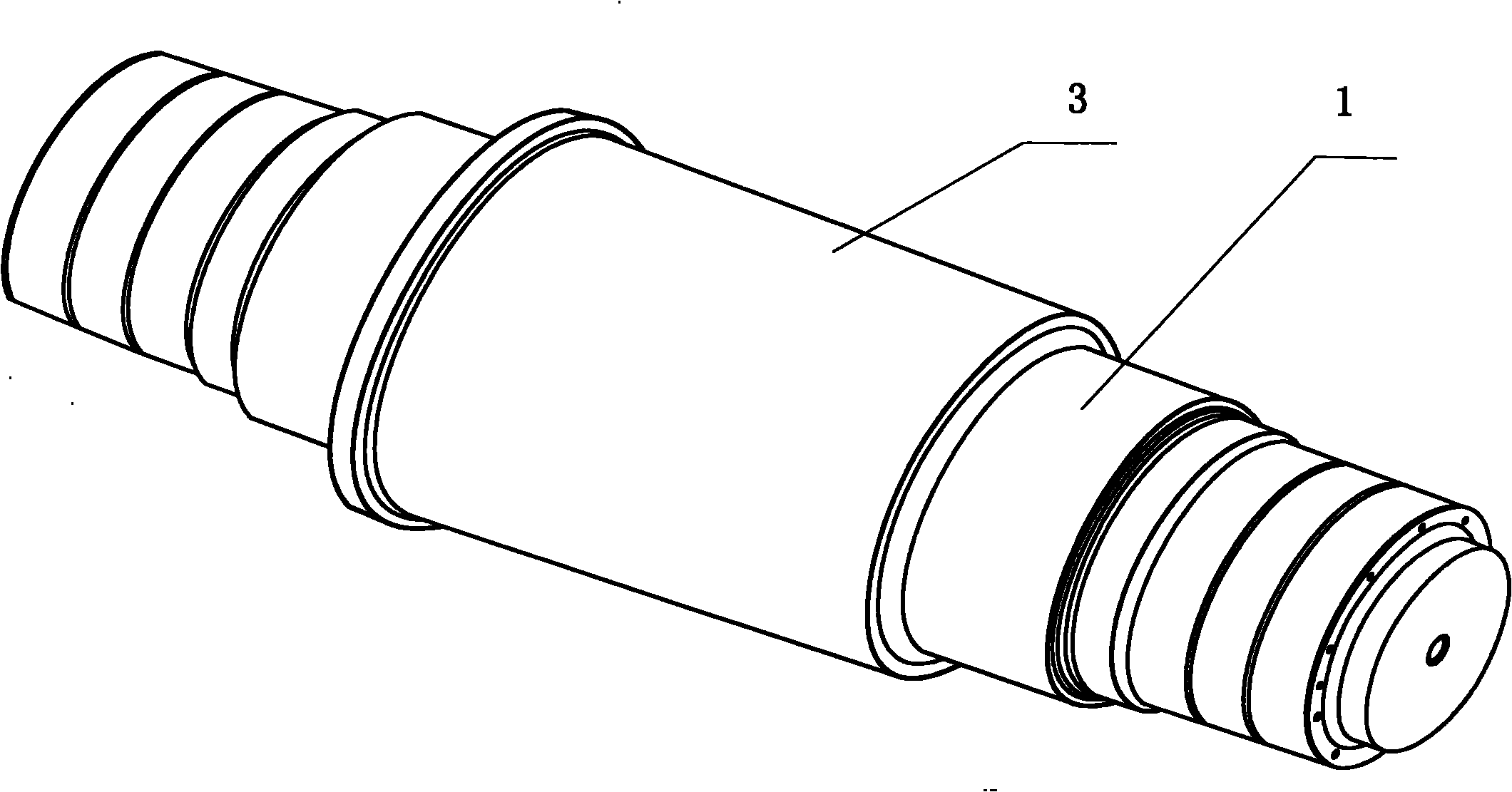

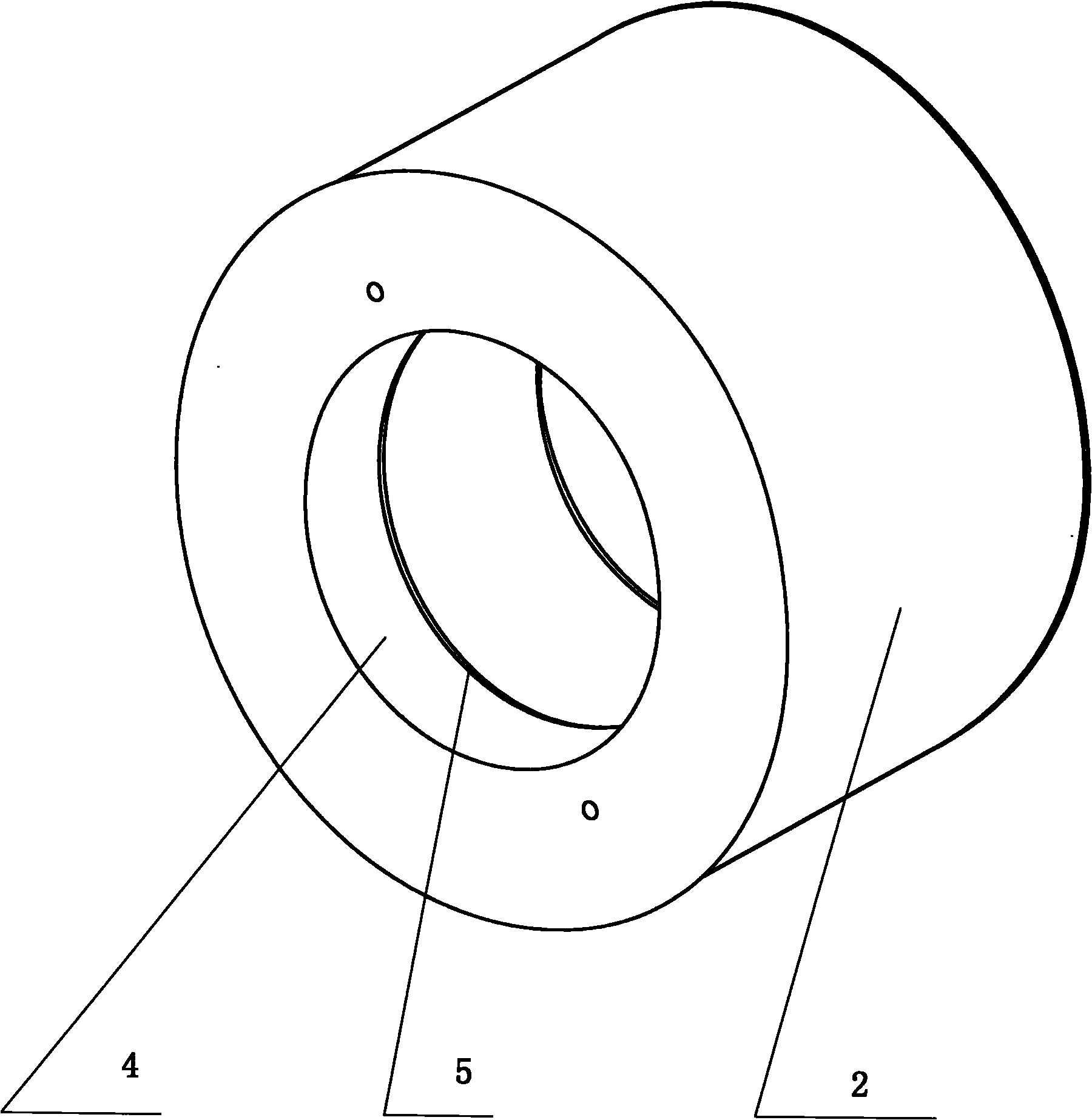

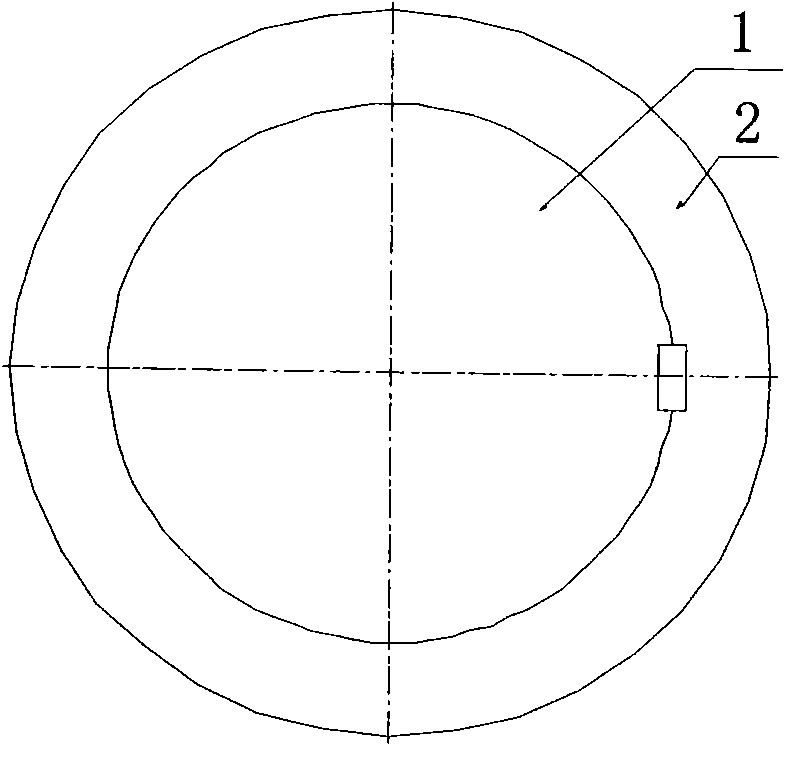

[0034] Such as figure 1 , 2 Shown: a split-type extrusion roller assembly structure and assembly method, the split structure adopts the form of conical surface matching: the matching part of the roller shaft is a conical surface, and the inner hole of the roller sleeve or the matching part of the outer tapered surface of the roller shaft are set to multiple channels Oil groove conical surface. The roller shaft and the roller sleeve are connected by interference fit, and the roller sleeve is assembled by hydraulic pressure. This assembly structure method using high-pressure oil to expand the inner hole of the roller sleeve greatly shortens the assembly cycle of the extrusion roller sleeve, greatly reduces the stress concentration phenomenon caused by the interference connection between the roller shaft and the roll sleeve, and improves the quality of the roll. The service life of the extrusion roller of the press and the grinding product is improved, thereby improving the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com