Chatter wind power generation apparatus

A technology of wind power generation device, resistance, applied in the field of tremor wind power generation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

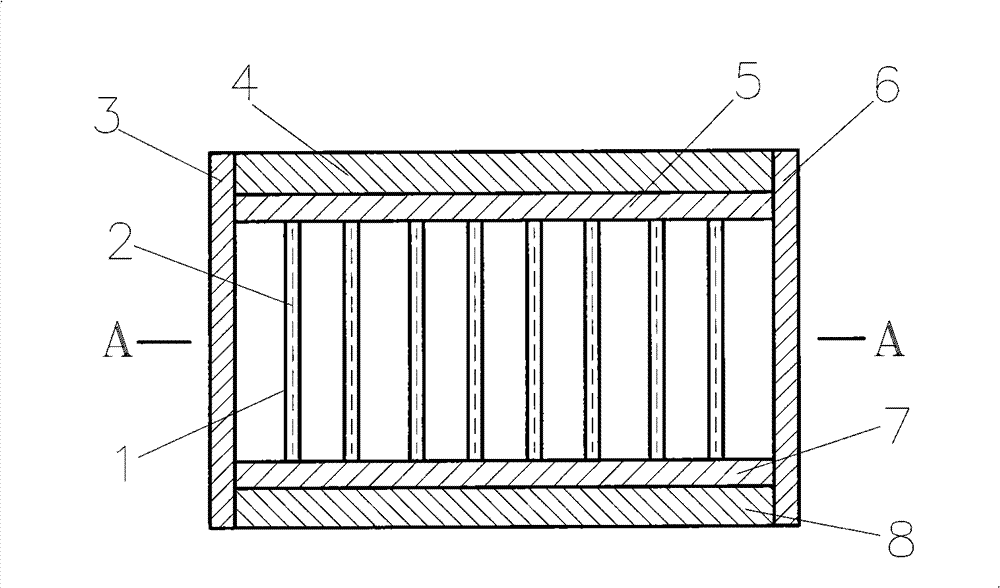

Embodiment 1

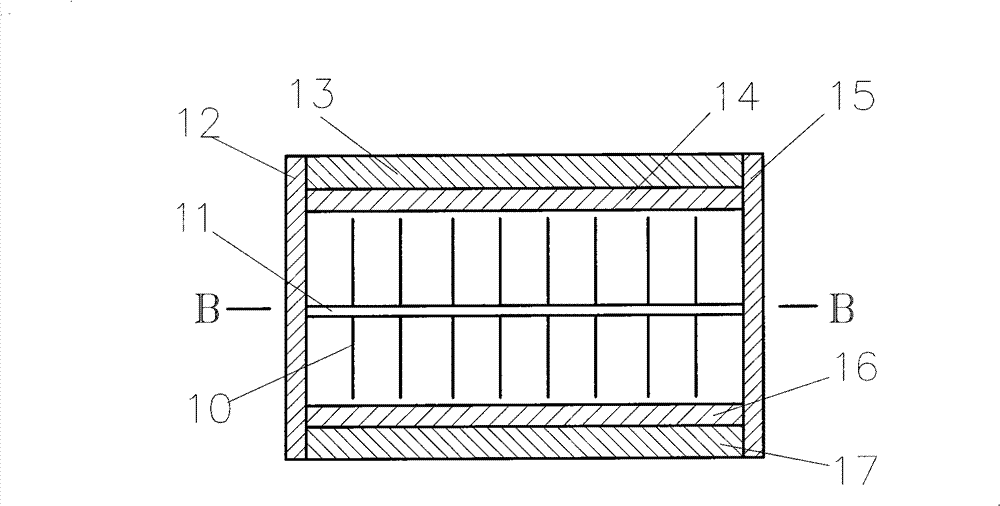

[0032] Embodiment three: as Figure 5 Figure 6 Show. On the upper surface of the magnetic plate 22, the magnetic conductive plate 21 is consolidated, and the magnetic conductive plate 25 is consolidated on the lower end surface of the magnetic plate 24; The left end face of magnetic plate 21, magnetic plate 24, magnetic permeable plate 25, magnetic permeable plate 23 is connected on the right end face of magnetic plate 22, magnetic permeable plate 21, magnetic plate 24, magnetic permeable plate 25; Intervals vertically fix some conductive sheets 19; the thickness direction of the conductive sheets 19 is perpendicular to the magnetic field lines of the magnetic field built by the magnetic plates 22 and the magnetic plates 24, and the conductive sheets 19 do not contact the magnetic plates 22; Figure 6 Shown, on the upper and lower end faces of the frame surrounded by the magnetic plate 20, the magnetic plate 23, the magnetic plate 22, the magnetic plate 21, the magnetic pla...

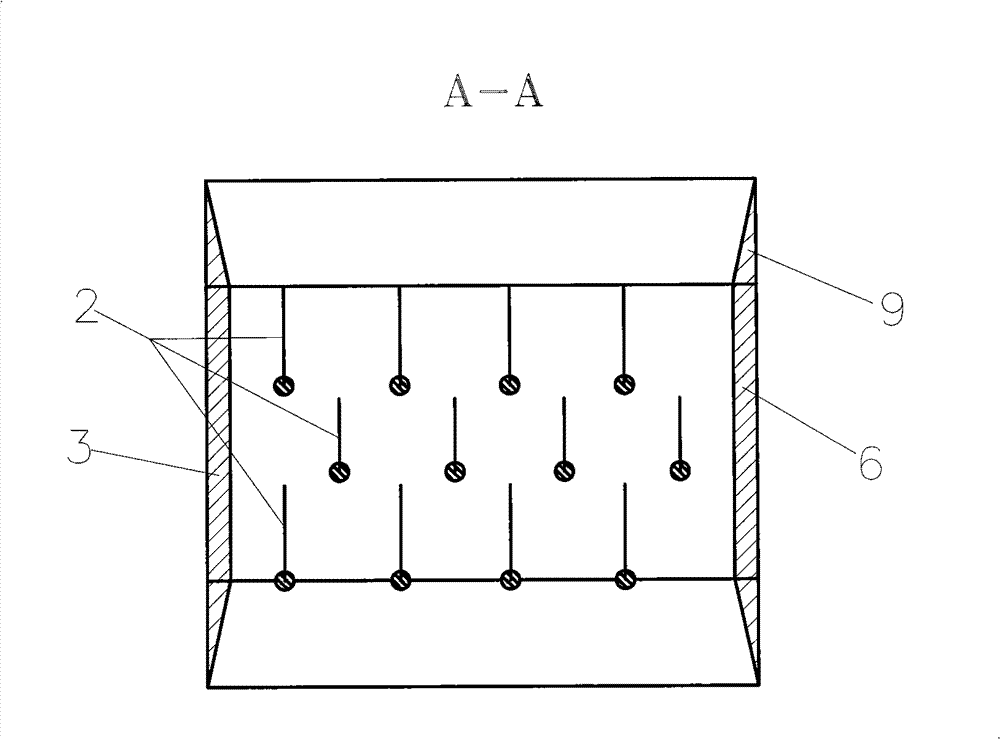

Embodiment 2

[0033] Embodiment four: as Figure 7 Figure 8 Show. On the upper surface of the magnetic plate 30, the magnetic conductive plate 29 is consolidated, and the magnetic conductive plate 33 is consolidated on the lower end surface of the magnetic plate 32; The left end face of magnetic plate 29, magnetic plate 32, magnetic permeable plate 33; The upper end face of end face, magnetic plate 32 vertically fixes some conductive sheets 27 at intervals; the thickness direction of conductive sheet 27 is perpendicular to the magnetic field lines of the magnetic field that magnetic plate 30 and magnetic plate 32 build, and each conductive sheet 27 does not contact each other; Figure 8 As shown, on the upper and lower end faces of the frame surrounded by the magnetic plate 28, the magnetic plate 29, the magnetic plate 30, the magnetic plate 33, the magnetic plate 32, and the magnetic plate 31, each connects a flow guide frame 34 with an inner inclined surface. Reduce the frame's resist...

Embodiment 3

[0034] Embodiment five: as Figure 9 to Figure 10 Show. On the upper end surface of magnetic plate 38, the magnetic conductive plate 37 is consolidated, and the magnetic conductive plate 41 is consolidated on the lower end surface of the magnetic plate 40; The left end face of magnetic plate 37, magnetic plate 40, magnetic permeable plate 41; The upper end face of end face, magnetic plate 40 vertically fixes some conductive sheets 35 at intervals, the thickness direction of conductive sheet 35 is perpendicular to the magnetic field line direction of magnetic field that magnetic plate 38 and magnetic plate 40 build, and each conductive sheet 35 does not contact each other; Figure 10 As shown, on the upper and lower end faces of the frame surrounded by the magnetic guide plate 36, the magnetic guide plate 37, the magnetic guide plate 38, the magnetic guide plate 41, the magnetic guide plate 40, and the magnetic guide plate 39, each connects a flow guide frame 42 with an inner in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com