Brake lamp switch for motor vehicle

A technology for brake lights and motor vehicles, which is applied to vehicle components, contact surface shape/structure, contact meshing, etc. Normal and long-term use, not easy to burn out and burn out, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

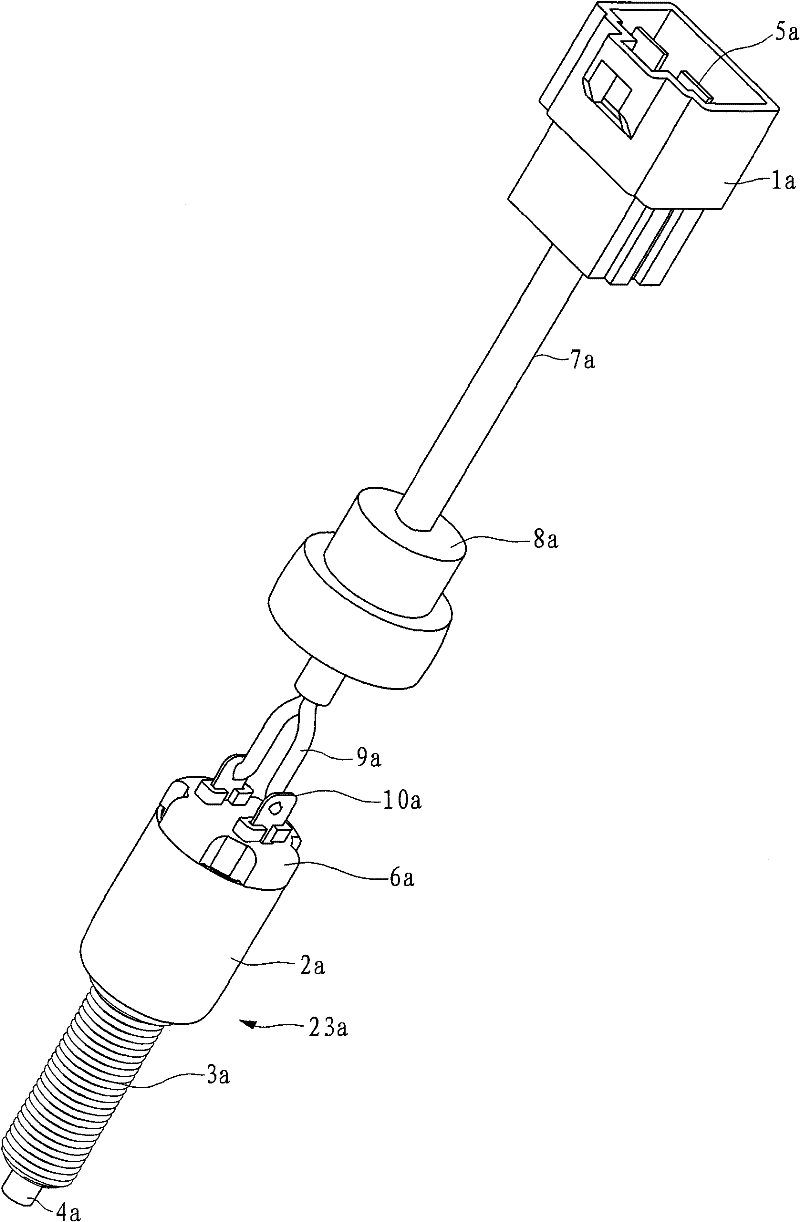

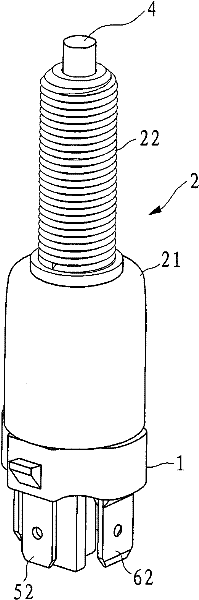

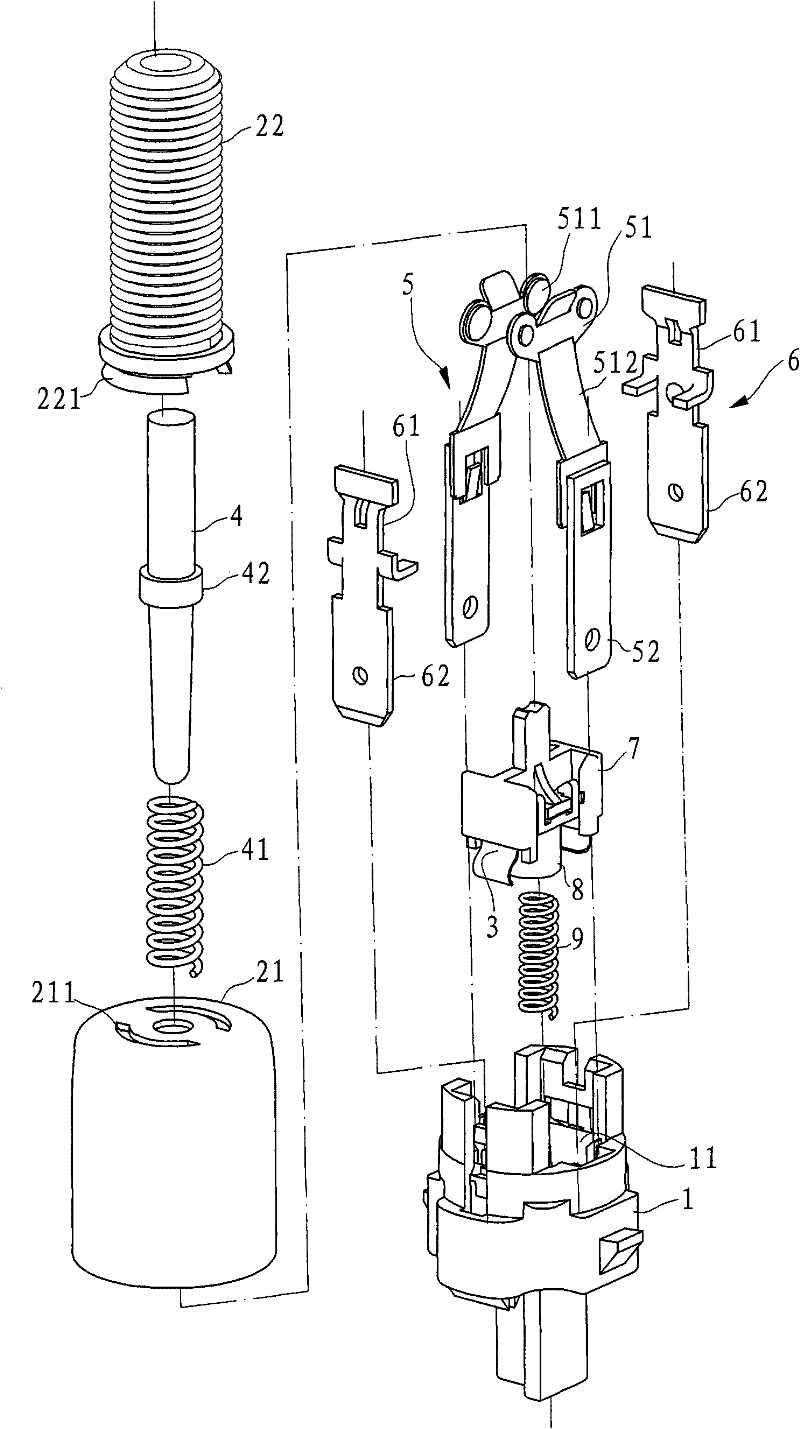

[0038] Such as figure 2 and image 3 As shown, the motor vehicle brake light switch in this embodiment includes a socket 1, a contact piece, a screw sleeve 2, a pole 4 and a reset member 41, the contact piece is located on the socket 1, and the screw sleeve 2 has a sleeve portion 21 and a The hollow screw part 22 extending from one end of the sleeve part 21, the sleeve part 21 is sleeved on the front face of the socket 1; the column rod 4 is inserted in the hollow screw part 22 of the screw sleeve and can move back and forth, and the reset part 41 always forces the column The head of the rod 4 leaves the socket 1 , and the sleeve part 21 has two insertion holes 211 on one end surface, and correspondingly, one end of the hollow screw part 22 has two insertion protrusions 221 fitted with the insertion holes 211 .

[0039] Such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com