Speed regulation and control system for lifting mechanism of tower crane

A technology of tower cranes and hoisting mechanisms, applied in the direction of clockwork mechanisms and hoisting devices, can solve problems such as increased maintenance costs, poor transmission performance, and increased energy consumption, so as to reduce electrical maintenance, improve bearing performance, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

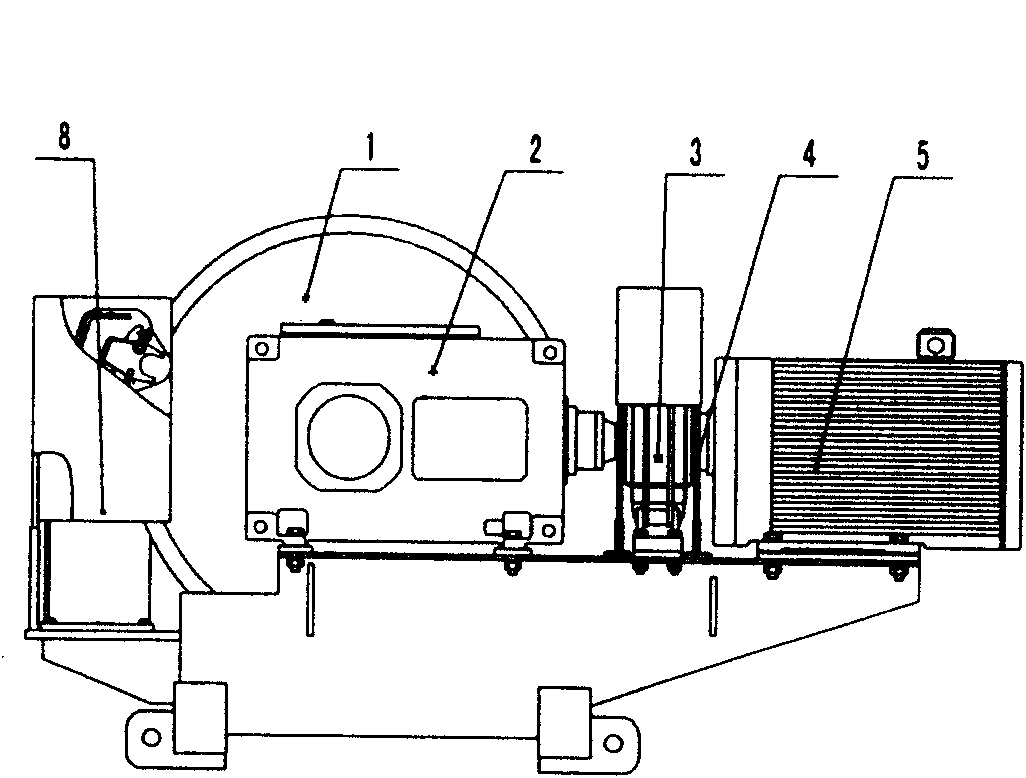

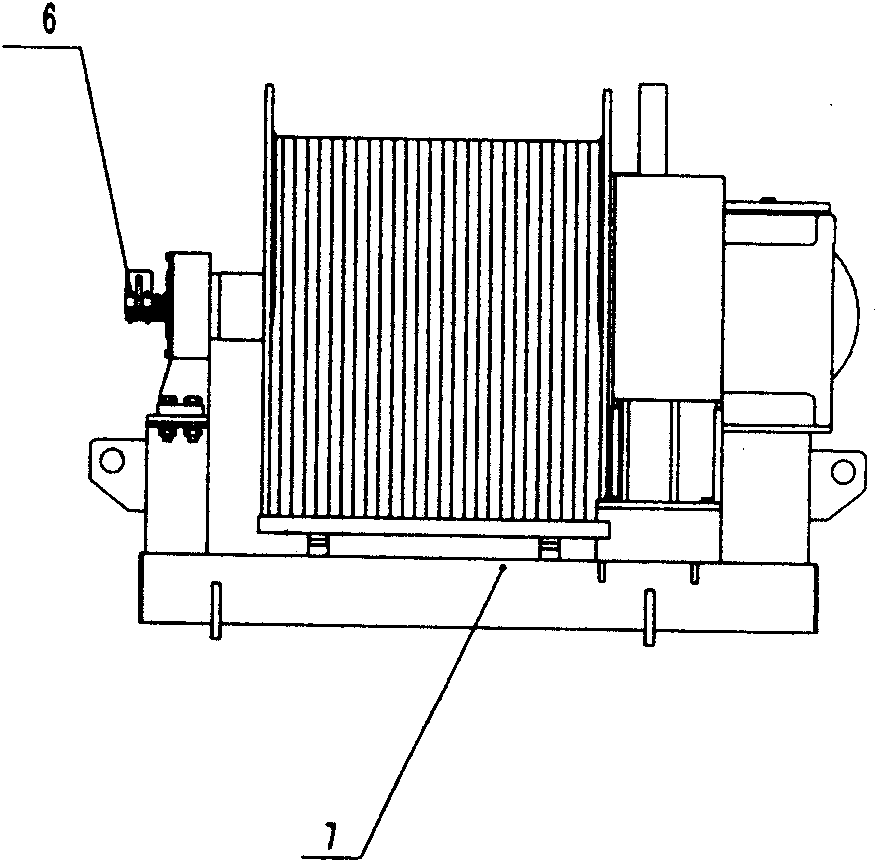

[0028] The hoisting mechanism of the tower crane has a double braking mechanism (such as figure 2 , image 3 , Figure 4 ), the lifting mechanism includes a reel 1, a reducer 2, a coupling 4, a motor 5 and an underframe 7, and the coupling 4 is equipped with a first brake—a hydraulic push rod brake 3, and the underframe 7 A second brake—hydraulic caliper brake device 8 is installed on the outer side corresponding to the reel 1, and a limiter 6 is installed on the shaft head of the reel 1. When the first brake fails, the second brake works to stop the reel directly, and the two sets of brake systems realize the double protection of the mechanism.

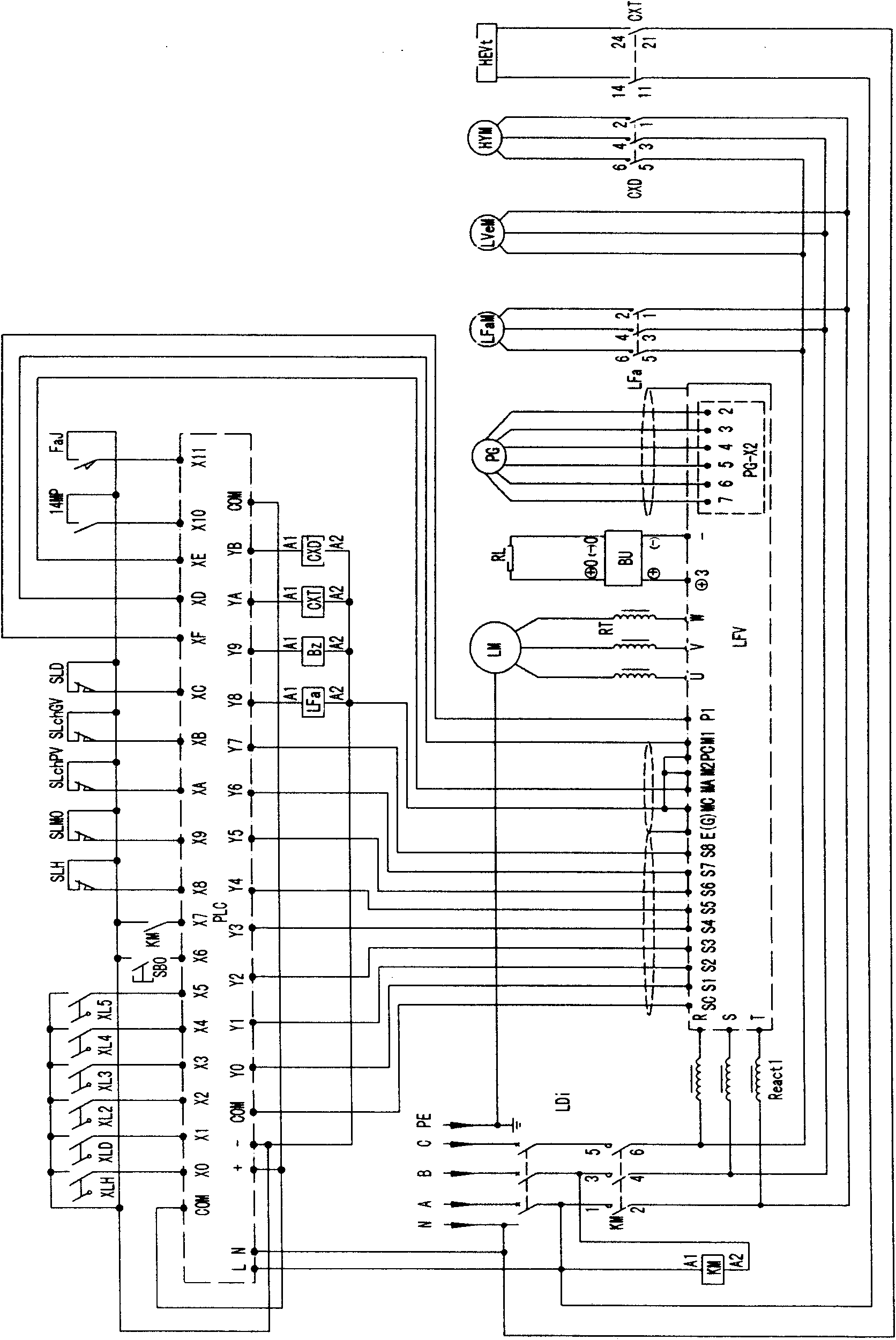

[0029] The frequency conversion and speed regulation transmission scheme of the hoisting mechanism of the tower crane adopts the "one drive one" scheme with one frequency converter and one motor. characteristics and high torque output capability, the motor adopts speed closed-loop control with pulse encoder. The drive frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com