Method for jointly removing carbon dioxide and sulfur dioxide from smoke

A combined removal and carbon dioxide technology, applied in chemical instruments and methods, separation methods, chemical separation, etc., to achieve the effects of low energy consumption, wide application range, and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

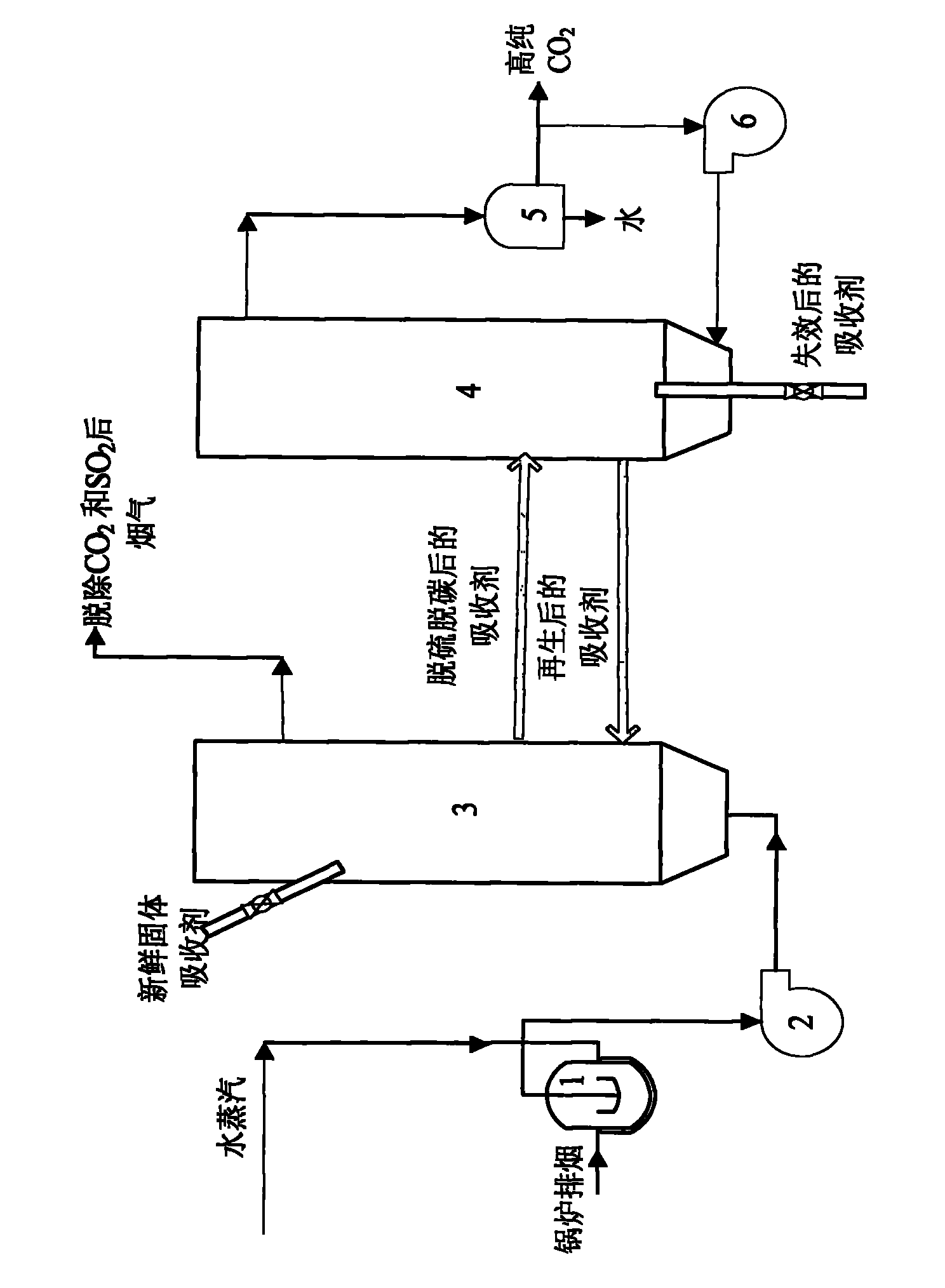

Method used

Image

Examples

Embodiment 1

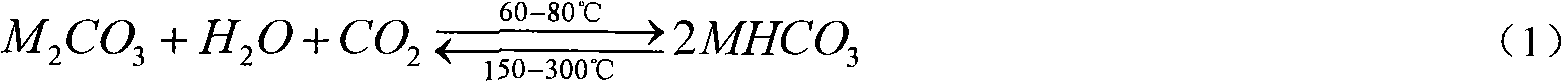

[0031] Power plant flue gas contains N 2 and part O 2 In addition, it contains about 10% water vapor and 10% to 20% CO 2 and 2500ppm SO 2 Wait. Put a certain amount of sodium carbonate or potassium carbonate or a mixture of sodium carbonate and potassium carbonate and activated alumina or activated carbon or magnesium oxide or a mixture of several substances to absorb absorbent particles prepared by impregnation or wet mixing or spraying in the flue gas In the absorption reactor, the temperature of the reactor is maintained between 60°C and 80°C, and the operation mode adopts the transport bed. When the flue gas passes through the reactor, CO 2 and SO 2 absorbed. CO removal 2 / SO 2 The final flue gas is directly discharged into the atmosphere through the flue and chimney. The reacted absorbent particles enter the regeneration reactor. The temperature of the regenerative bed reactor is maintained between 150°C and 300°C, and the operation mode adopts bubbling bed. Th...

Embodiment 2

[0033] Power plant flue gas contains N 2 and part O 2 In addition, it contains less water vapor, 10% to 20% of CO 2 and 2500ppm SO2 Wait. Set up a bypass on the exhaust pipe of the steam turbine, lead out a part of the low-pressure steam and adjust it to 10% through the flow regulating device and mix it with the flue gas, mix a certain amount of sodium carbonate or potassium carbonate or a mixture of sodium carbonate and potassium carbonate with activated alumina or activated carbon Or magnesium oxide or a mixture of several substances, the absorbent particles prepared by impregnation method, wet mixing method or spraying method are placed in the flue gas absorption reactor, and the temperature of the reactor is maintained between 60°C and 80°C. Bubble bed. When the flue gas passes through the reactor, CO 2 and SO 2 absorbed. CO removal 2 / SO 2 The final flue gas is directly discharged into the atmosphere through the flue and chimney. The reacted absorbent particles e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com