Coated bearing

A bearing cavity, bearing assembly technology, applied in the direction of bearings, ball bearings, bearing components, etc., to achieve the effect of improving lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

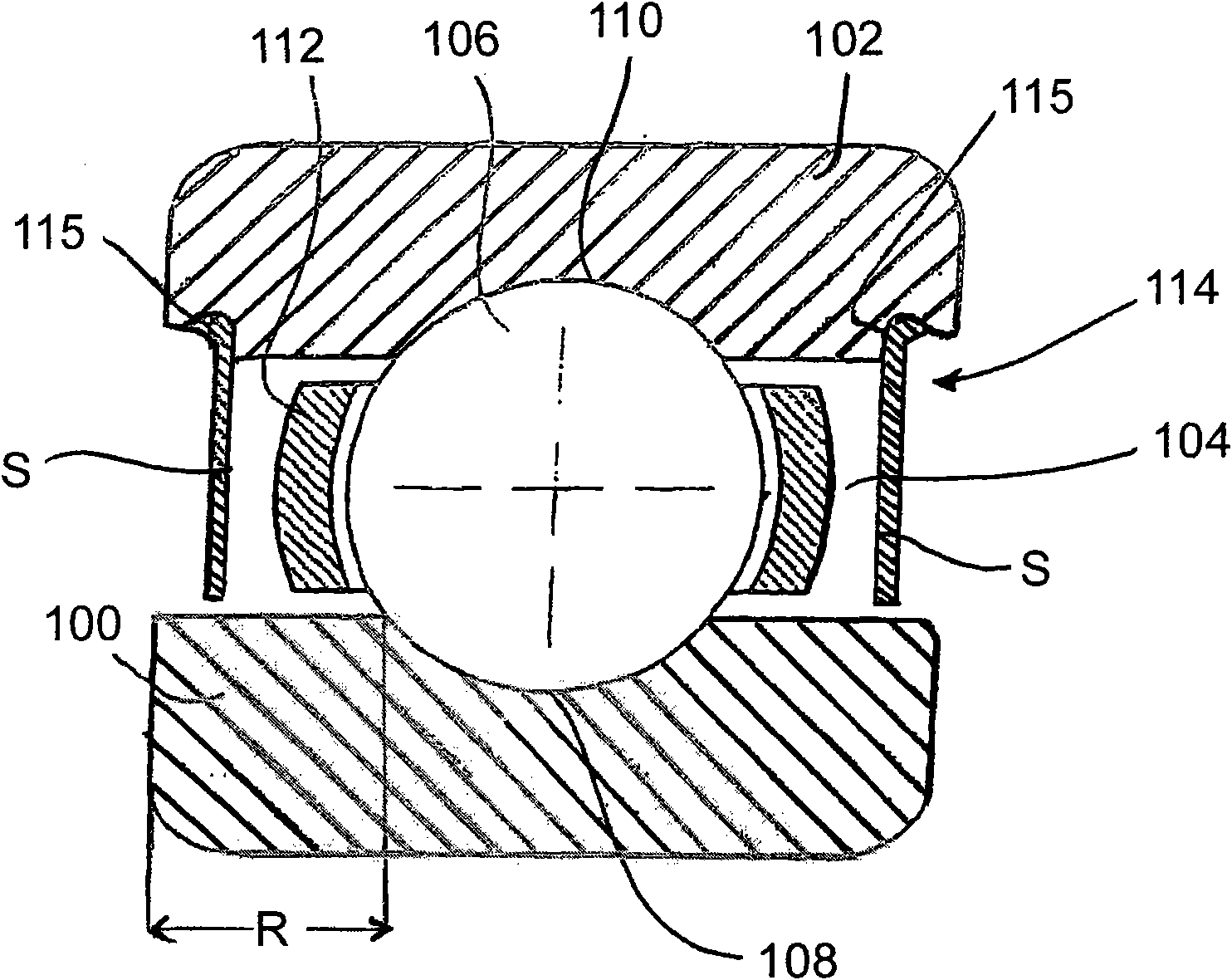

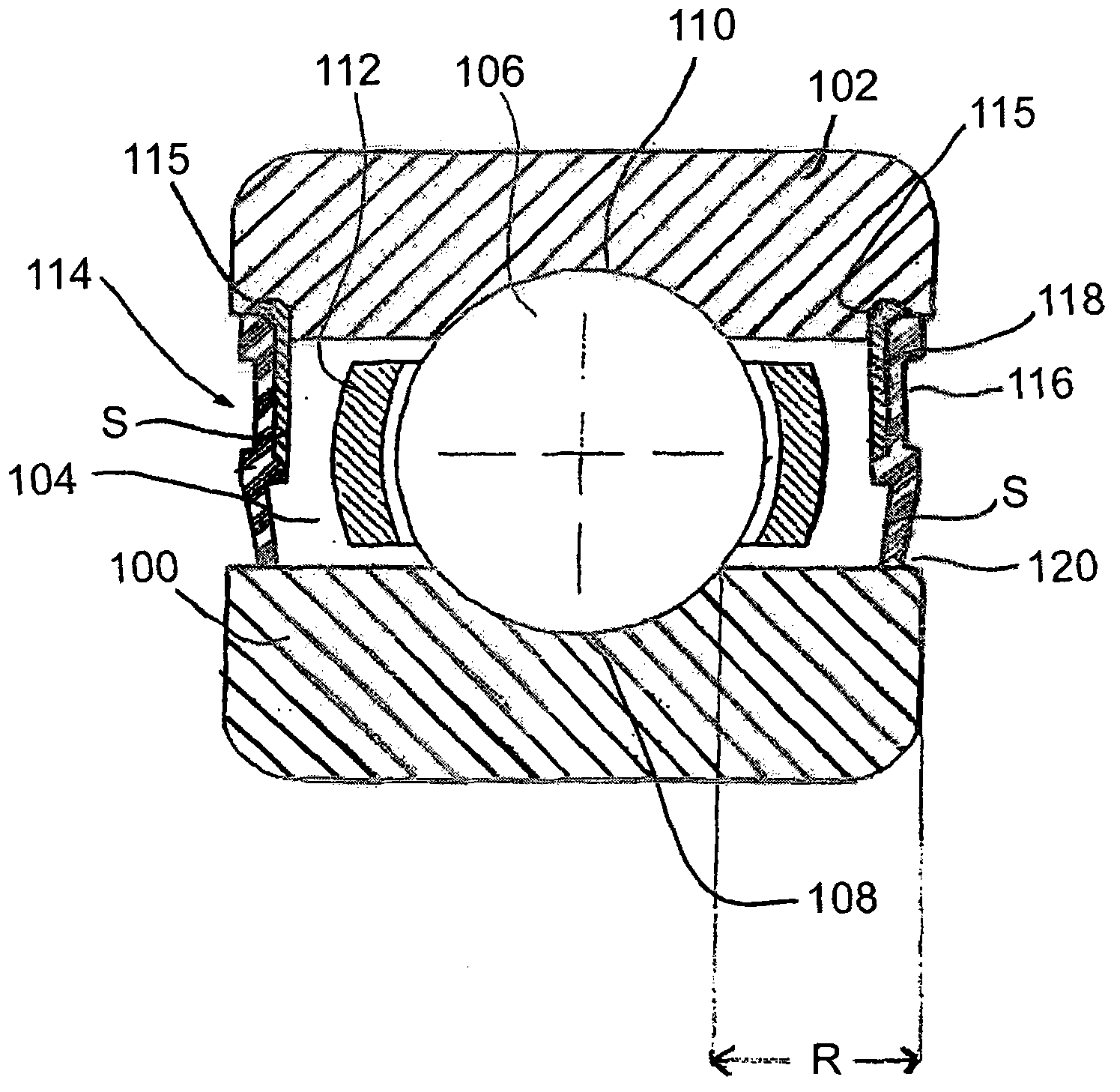

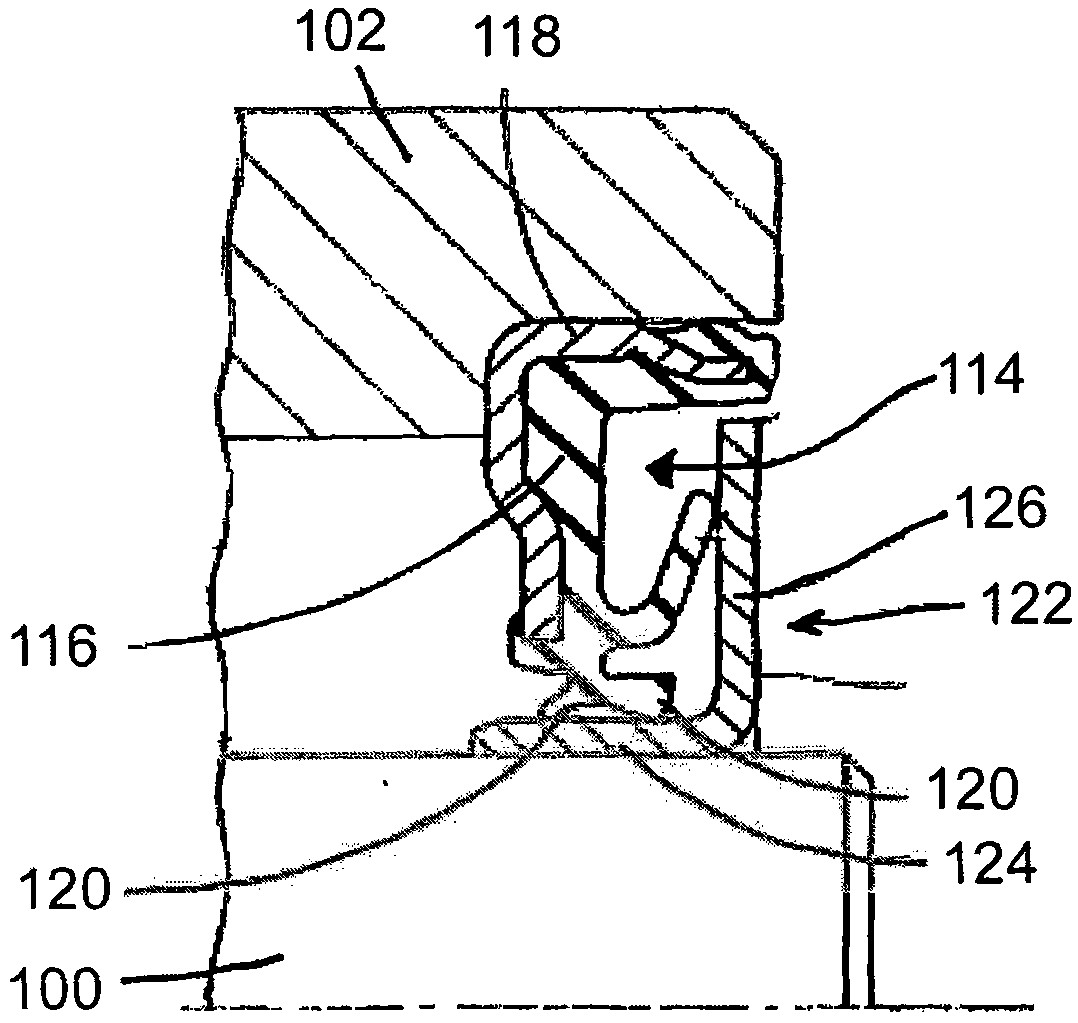

[0038] Figure 1a-1b An embodiment of a bearing assembly according to the invention is shown comprising an inner ring 100 and an outer ring 102 between which a bearing cavity 104 is defined. The inner and outer rings are rotatably coupled by rolling bodies 106 arranged on opposing raceways 108, 110 in the inner and outer rings, respectively. The rolling elements are held in a cage 112 . To lubricate the raceway contacts during operation, the bearings are provided with a grease or oil lubricant (not shown). The bearing is also provided with at least one sealing member 114 mounted in a groove 115 in the outer ring 102 to at least substantially span the radial gap of the bearing cavity 104 .

[0039] The exemplary embodiment is an example of a bearing having a rotating inner ring and a non-rotating outer ring. This is the most common bearing arrangement, but the invention is also applicable to bearing arrangements in which the outer ring is rotatable while the inner ring remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com