Evaporation heat transfer pipe

A technology of heat transfer tubes and outer fins is applied in the field of heat transfer tubes to achieve the effects of improving heat transfer efficiency, enhancing boiling heat transfer, and enhancing evaporation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

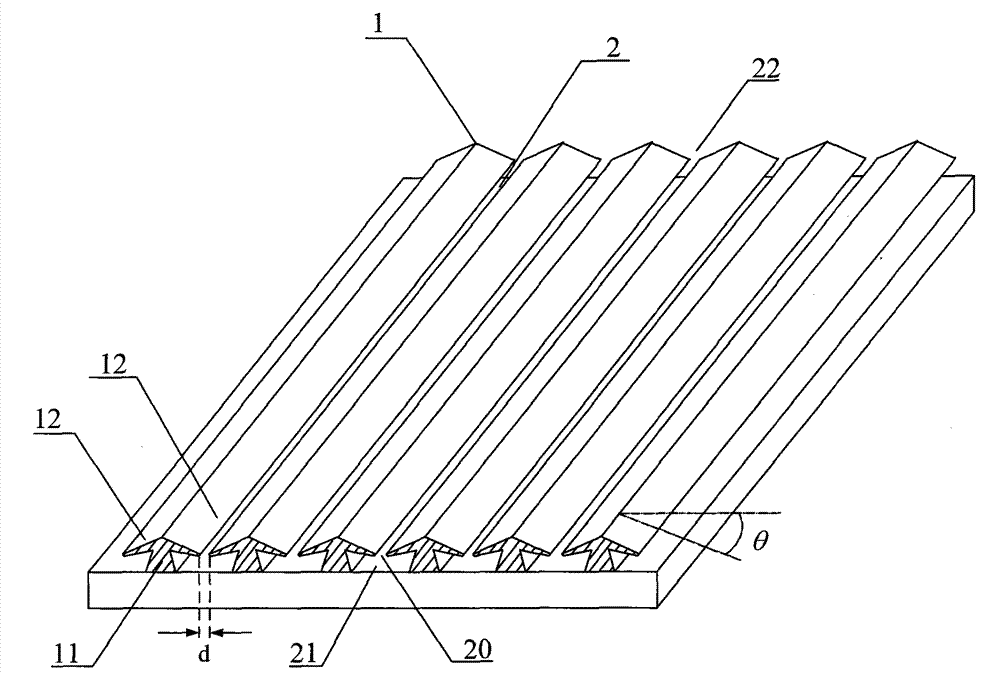

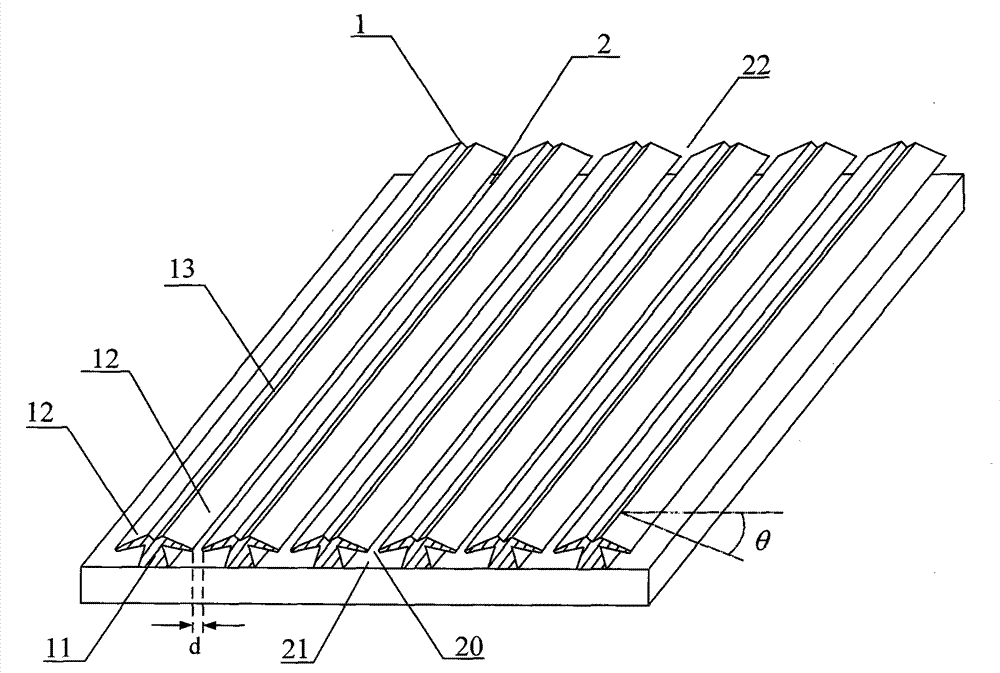

[0026] refer to figure 1 , shows a schematic diagram of the horizontally expanded structure of the first embodiment of the fin portion of the evaporating heat transfer tube. It is assumed that in the present embodiment, the fin portion of the evaporative heat transfer tube is disposed on the outer surface of the evaporative heat transfer tube. Such as figure 1 As shown, the fin portion includes: a plurality of outer fins 1 distributed in parallel, and inter-fin grooves 2 are formed between two adjacent outer fins 1 . Each outer fin 1 includes: a main wing 11 and two secondary wings 12 . The two secondary wings 12 are arranged on the top of the main wing 11, and a certain angle θ is formed between the top and the horizontal end line, and the range of θ can be: 0°≤θ≤90°. When θ=0°, the cross section of the outer fin 1 is T-shaped; when 0°<θ<90°, the two secondary wings 12 are inclined downward respectively, and the cross section of the outer fin 1 is similar to an umbrella sh...

Embodiment 2

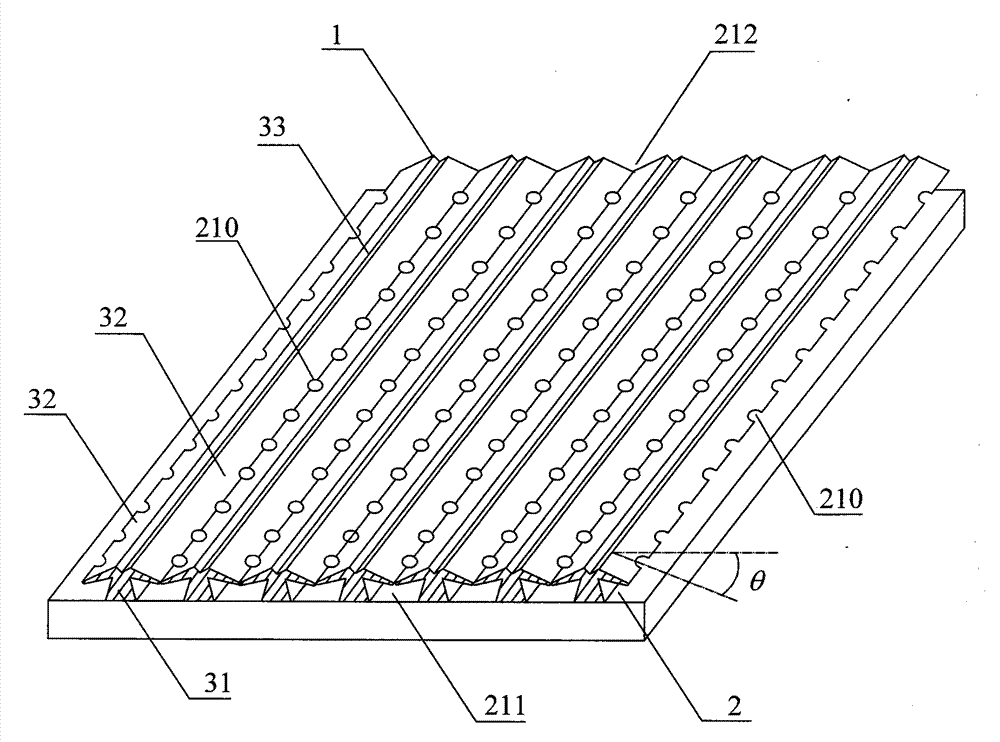

[0032] refer to image 3 , shows a schematic diagram of the horizontally expanded structure of the second embodiment of the fin portion of the evaporating heat transfer tube. Likewise, in this embodiment, it is assumed that the fins of the evaporating heat transfer tubes are disposed on the outer surface of the evaporating heat transfer tubes. Such as image 3 As shown, the fin portion includes: a plurality of outer fins 1 distributed in parallel, and inter-fin grooves 2 are formed between two adjacent outer fins 1 . Each outer fin 1 includes: one main wing 31 and two secondary wings 32 . The two secondary wings 32 are arranged on the top of the main wing 31, and the angle θ formed between the top and the horizontal end line is in the range of: 0°≤θ≤90°. When θ=0°, the cross-section of the outer fin 1 is T-shaped; when 0°<θ<90°, the two secondary wings 32 are inclined downward respectively, and the cross-section of the outer fin 1 is similar to an umbrella shape; When θ=90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com