Non-coal leaking front air-outlet reciprocating grate segment for large suspension-type reciprocating grate

A reciprocating grate and hanging technology, applied in the direction of mobile grate, grate, lighting and heating equipment, etc., can solve the problems left over from history and restrict the large-scale development of reciprocating grate boilers, so as to prevent high temperature burning, Guaranteed against thermal cooling and mechanical strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

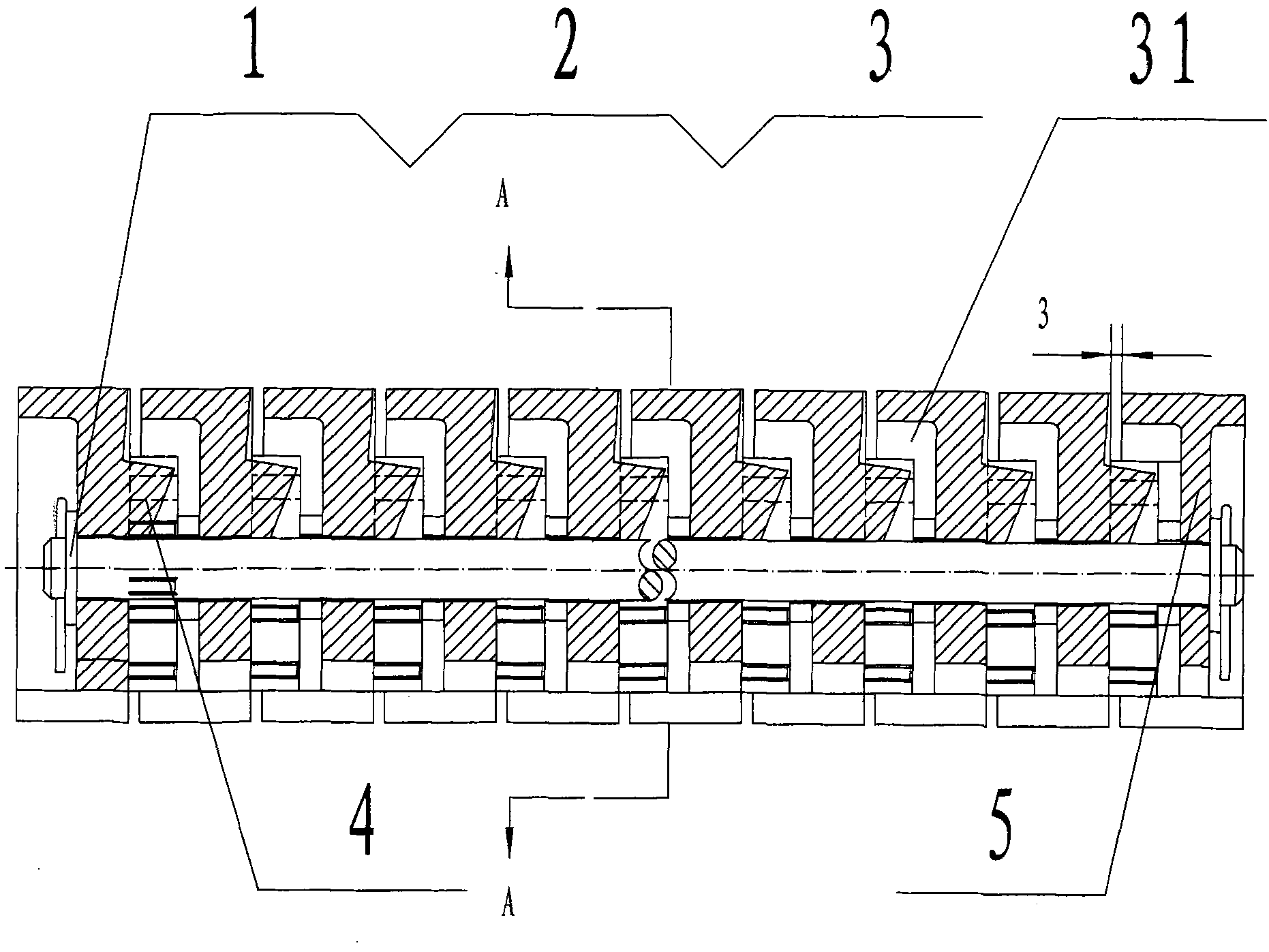

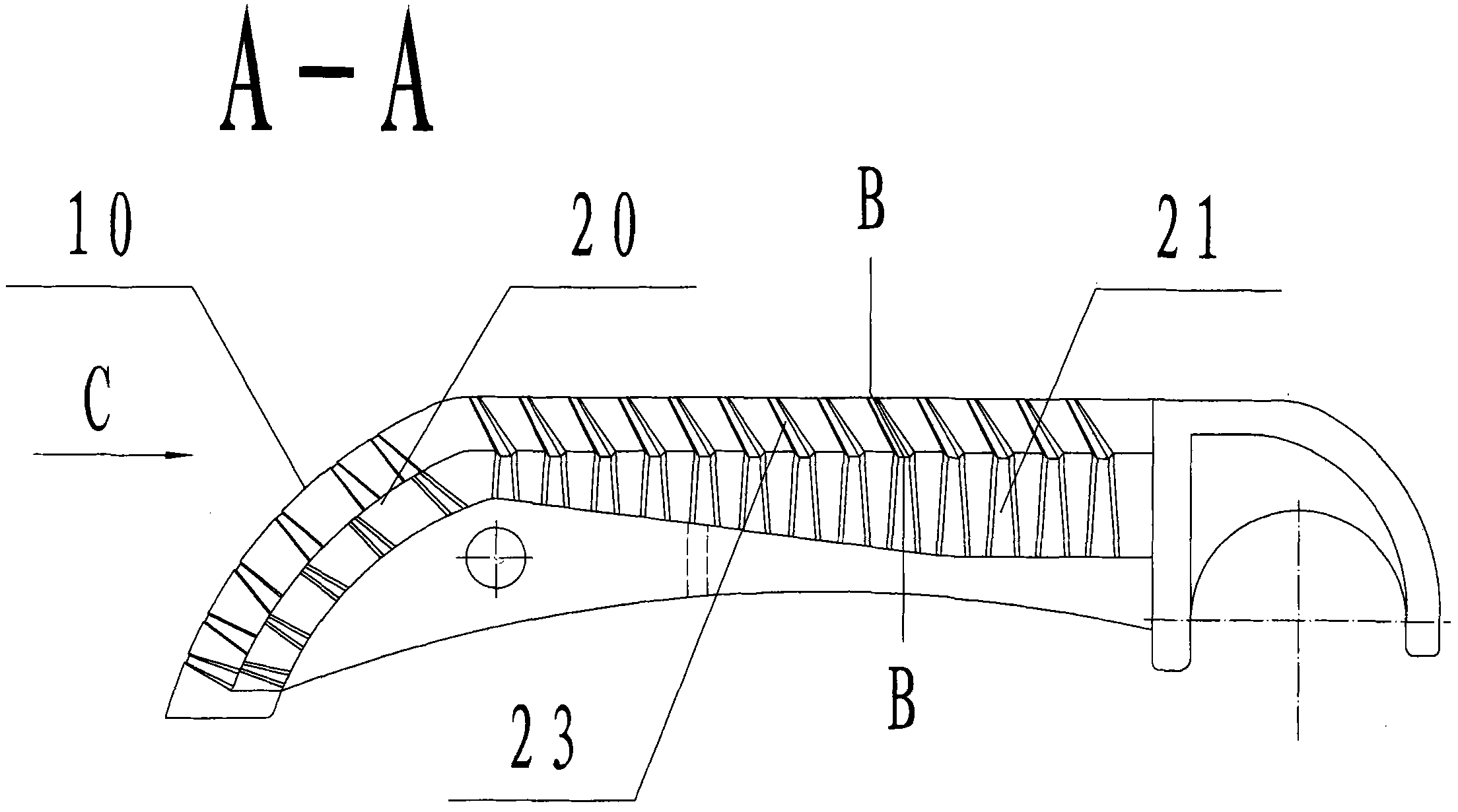

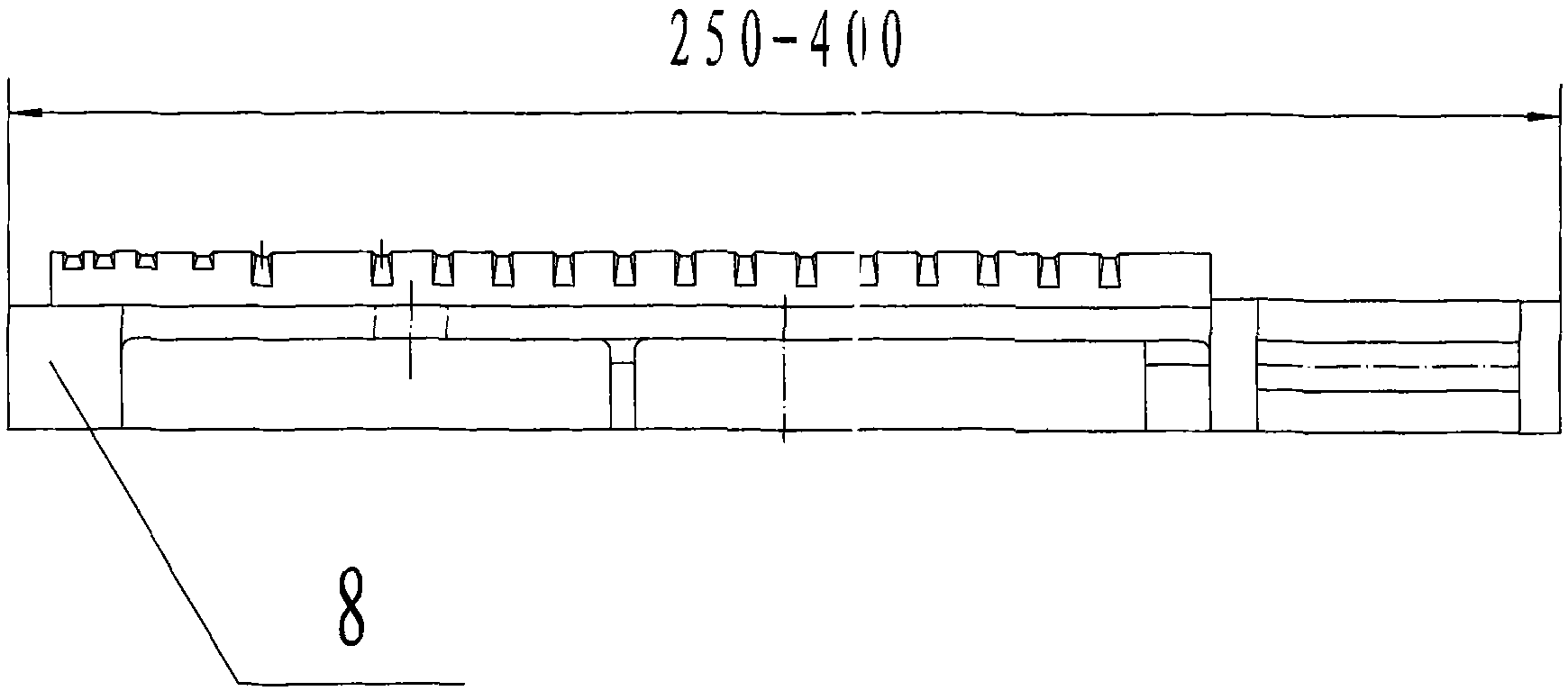

[0050] The large-scale suspended movable propulsion type industrial reciprocating grate of the present invention is a unit assembly respectively installed on the water-cooled suspended movable propelling frame unit or the water-cooled fixed frame unit; wherein the left piece (4) of the large-scale reciprocating grate is The right piece (5) is connected with the connecting limit pin (1), washer (2) and cotter pin (3) respectively to complete the connection between the grate pieces, making them independent reciprocating grate piece units; installed in the water-cooled The movable reciprocating grate unit (6) on the suspended movable propulsion frame unit performs reciprocating coal pushing motion on the reciprocating grate fixed piece unit (7) installed on the water-cooled suspended fixed propulsion frame unit, so as to realize the promotion of various combustion processes. Under the circumstances of burning coal seam fire, coal seam pushing and rolling and coke breaking combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com