Spindle bearing device of rotary screw rod compressor

A technology of screw compressor and main shaft support, which is applied to parts of pumping devices for elastic fluid, pump parts of rotary piston type/oscillating piston type, mechanical equipment, etc. Problems such as low bearing capacity and poor motion stiffness of roller bearings can achieve the effect of improving running accuracy and its working life, good working stability and improving running accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

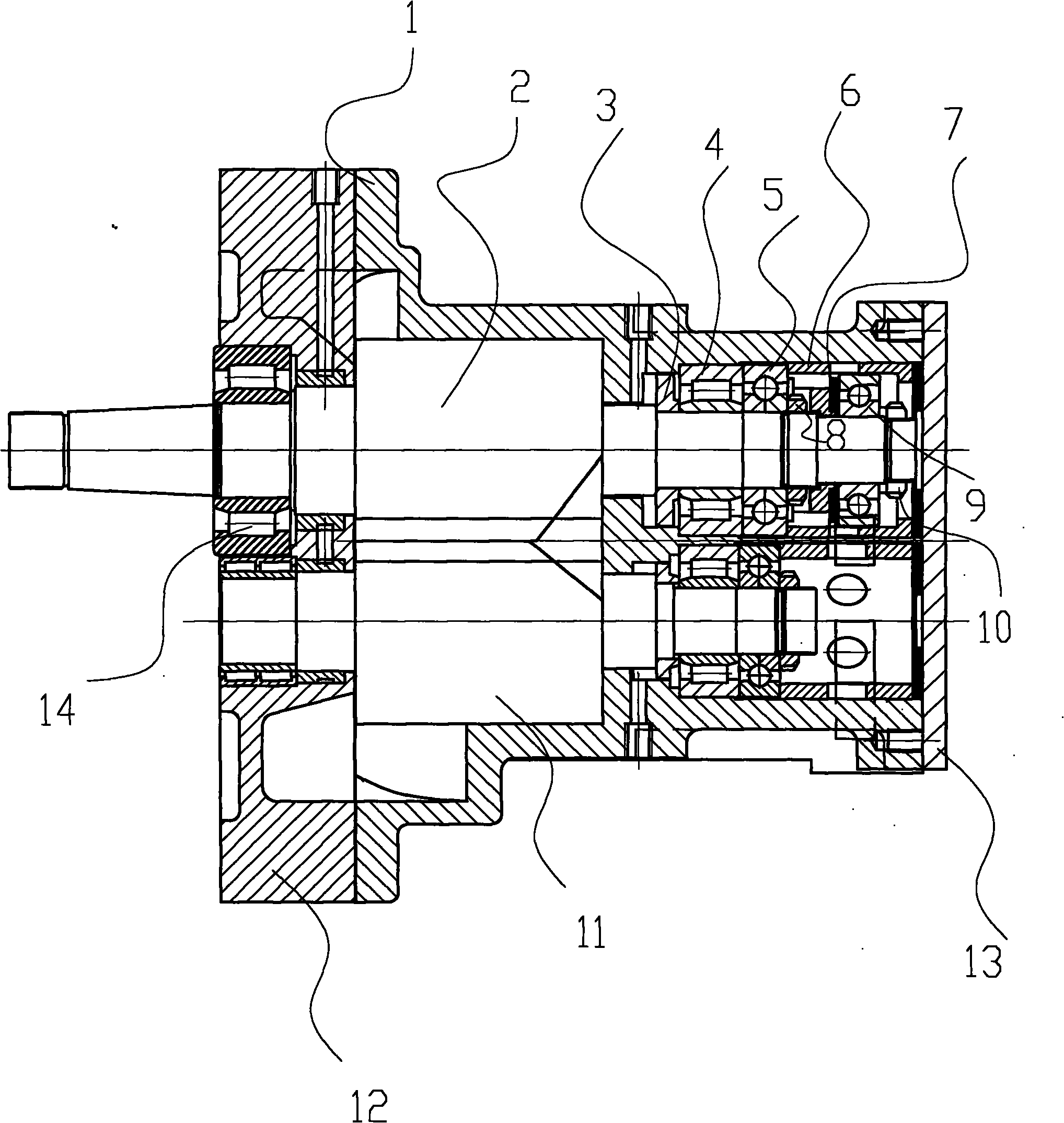

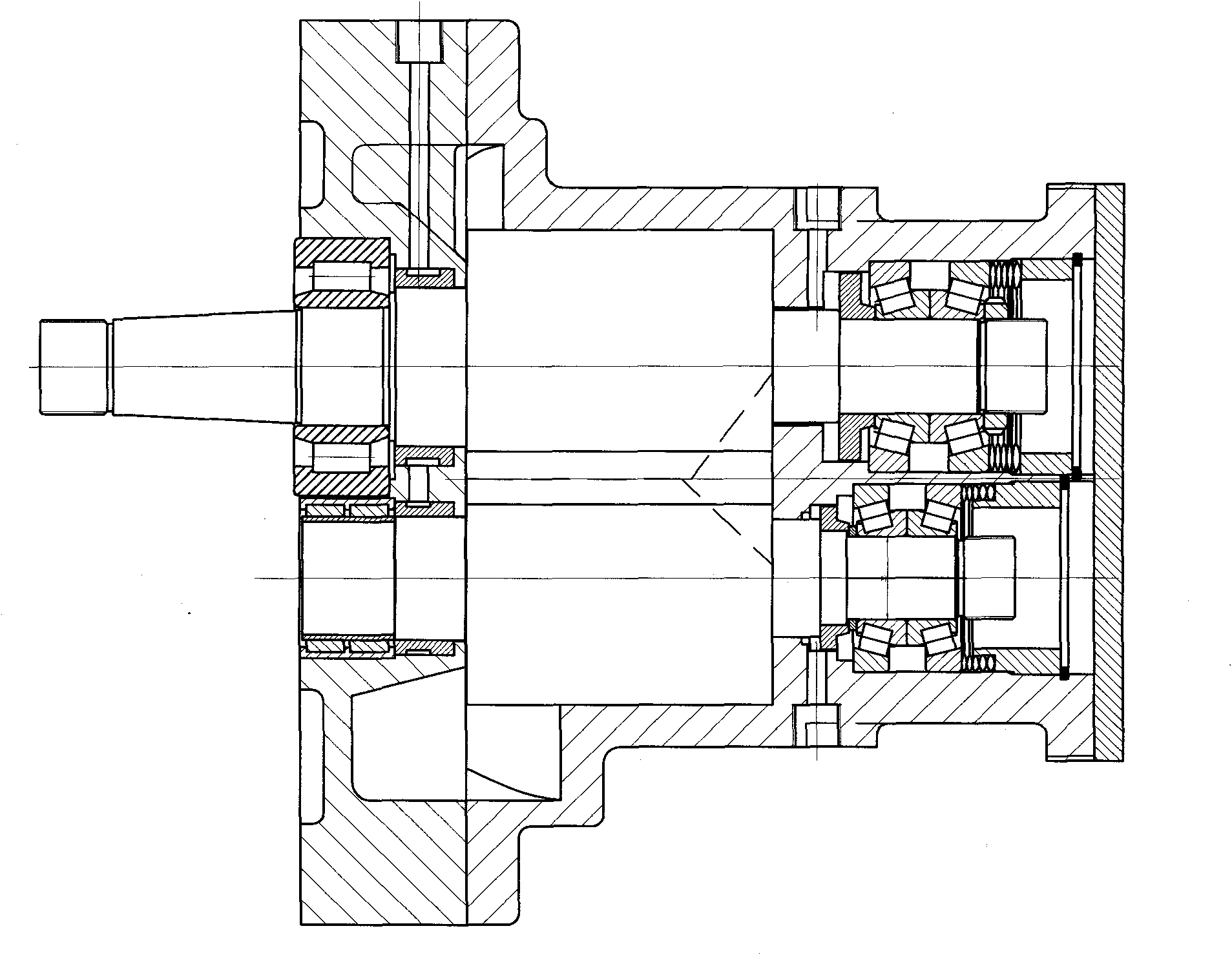

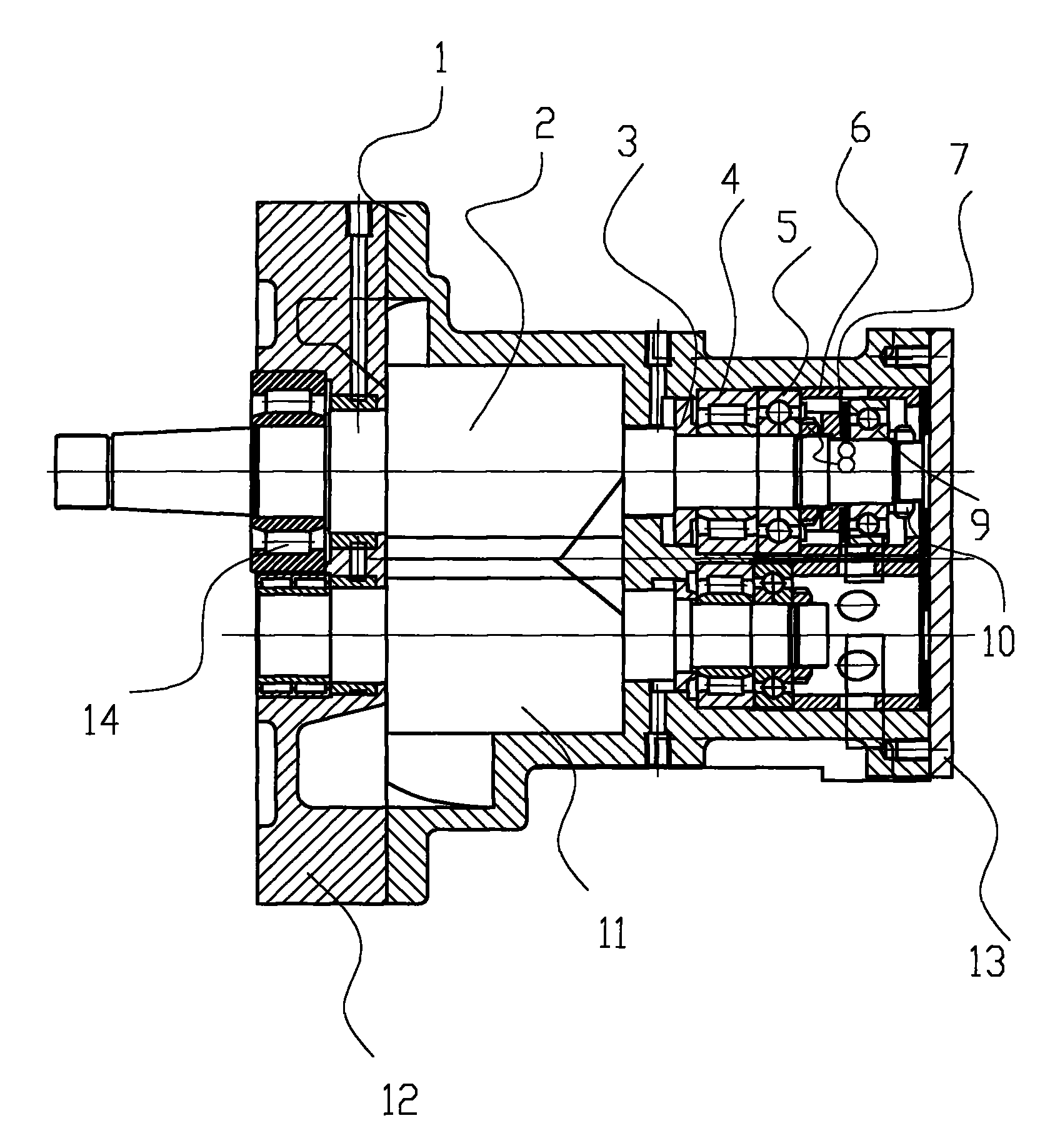

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] figure 1 An embodiment of the present invention is shown, which includes a housing 1 configured with a pair of intermeshed rotors; the front end of one of the rotors can be driven by a motor or various internal combustion engines to form the main shaft 2 of the screw compressor, and the other The rotor forms the driven shaft 11 of the screw compressor.

[0019] The rear end of the main shaft 2 is provided with two journal bearing surfaces of different diameters, of which the journal bearing surface of the large diameter is arranged in sequence with heavy-duty radial roller bearings 4 and four-point contact ball bearings 5, while the journal bearing surfaces of small diameter An angular contact ball bearing 9 is arranged on the supporting surface; the outer diameter of the heavy radial roller bearing 4 is fixed in the matching hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com