One-way moisture-transfer all-cotton spunlaced nonwoven as well as product and preparation method thereof

A spunlace non-woven, unidirectional wet-guiding technology, applied in textiles and papermaking, non-woven fabrics, plant fibers, etc., can solve the problem that it is difficult to meet the requirements of light and thin products, poor air permeability and comfort, and difficult craftsmanship and other problems, to achieve a good one-way moisture conduction effect, avoid the reverse flow of water, and avoid the effect of increasing the thickness of the non-woven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

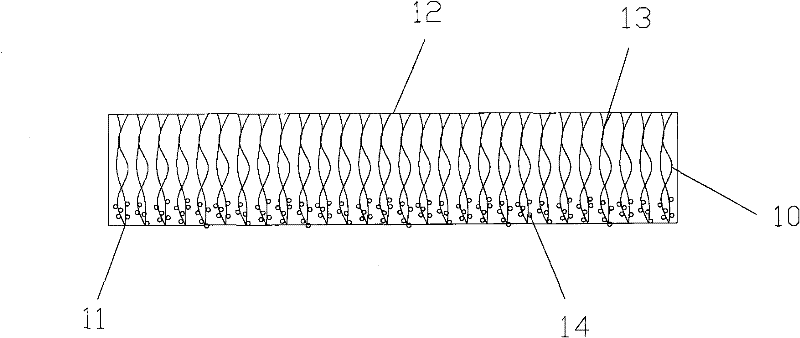

[0027] like figure 1 As shown, the all-cotton spunlace nonwoven matrix 10 consists of cotton fibers 13 entangled with each other. The all-cotton spunlace non-woven fabric base 10 has a hydrophobic surface 11 and a hydrophilic surface 12, wherein the hydrophobic surface 11 contains a hydrophobic substance. In this embodiment, the surface of the cotton fibers 13 located on the hydrophobic surface 11 is covered with a hydrophobic film layer, which contains nano wool particles 14 . These wool particles 14 are actually nano wool protein particles extracted from natural wool in a certain way. Compared with the fiber 13, its hydrophilic performance is reduced, so an additional pressure difference is generated between the hydrophobic surface 11 and the hydrophilic surface 12 to form a differential capillary effect, and the moisture in contact with the hydrophobic surface 11 can be unidirectionally transported along the cotton fiber 13. The water surface 12 avoids the backflow of moi...

no. 2 example

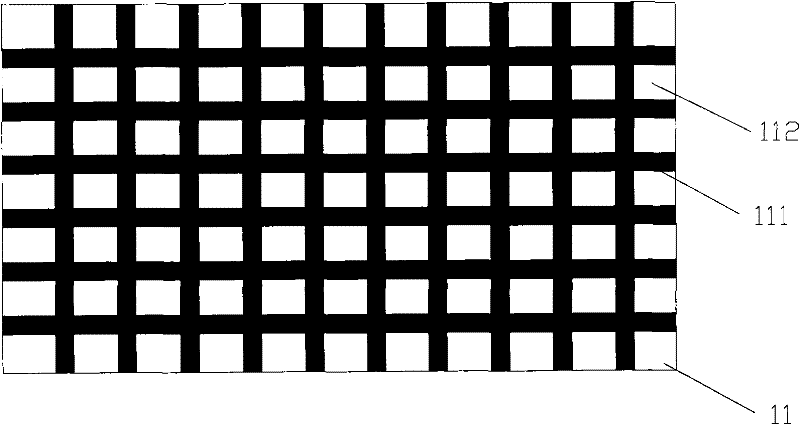

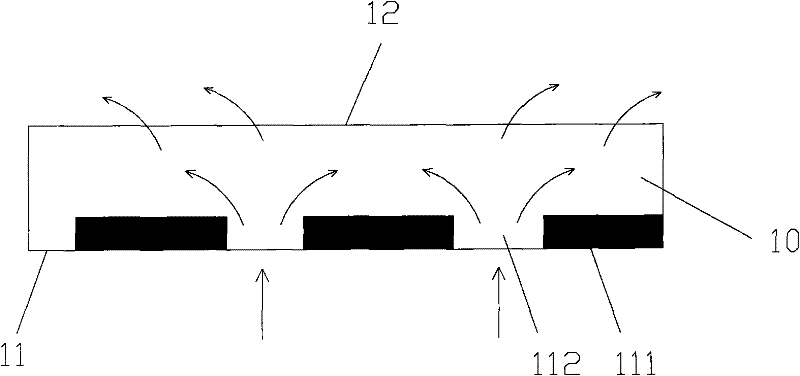

[0029] In this embodiment, the hydrophobic substance contained in the hydrophobic surface 11 of the all-cotton spunlace non-woven fabric is a hydrophobic film layer distributed on the hydrophobic surface 11 in a mesh shape, and contains nano wool particles 14 therein. In this embodiment, the cotton spunlace non-woven fabric can be finished by using the nano wool emulsion by flat screen printing. Only the surface of the cotton fibers 13 in the printing area is covered with a hydrophobic film layer. The hydrophobic surface 11 of the spun cloth substrate forms a regular or irregular mesh pattern, and is interlaced with the exposed areas formed by the cotton fibers 13 without the hydrophobic film layer, for example, it can be designed as a densely distributed porous pattern (including round holes, squares, etc.). holes, etc.), grid patterns, etc.

[0030] like figure 2 and image 3 As shown, in this embodiment, the printing area 111 forms a certain square grid pattern on the hy...

no. 3 example

[0034] like Figure 4 As shown, when the hydrophobic substance is a nano-wool emulsion containing nano-wool particles 14, or is called a nano-wool protein emulsion, the unidirectional wet-conducting cotton spunlace non-woven fabric manufacturing method of the present embodiment comprises the following steps:

[0035]Step S101 : spray the nano wool emulsion on one side of the cotton spunlace non-woven fabric substrate 10 through a spraying process, so that the nano wool emulsion is coated on the surface of the cotton fiber 13 of the hydrophobic surface 11 to form a hydrophobic film layer. The average particle size of the particles is nanoscale, eg 75 nm. The amount of spraying and process parameters are controlled according to specific needs, and try to ensure that the nano wool emulsion will not penetrate into the hydrophilic surface 12 of the base 10 of the cotton spunlace non-woven fabric.

[0036] Specifically, the nano-wool emulsion of this embodiment can be obtained by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com