Supercritical CO2 method for extracting barbadosnut seed oil and product thereof

A Jatropha curcas seed and supercritical technology is applied in the direction of oil/fat production and fat production, which can solve the problems of organic solvent residue, poor oil sensory quality, low yield and the like, and achieves improved extraction rate, easy operation and extraction. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

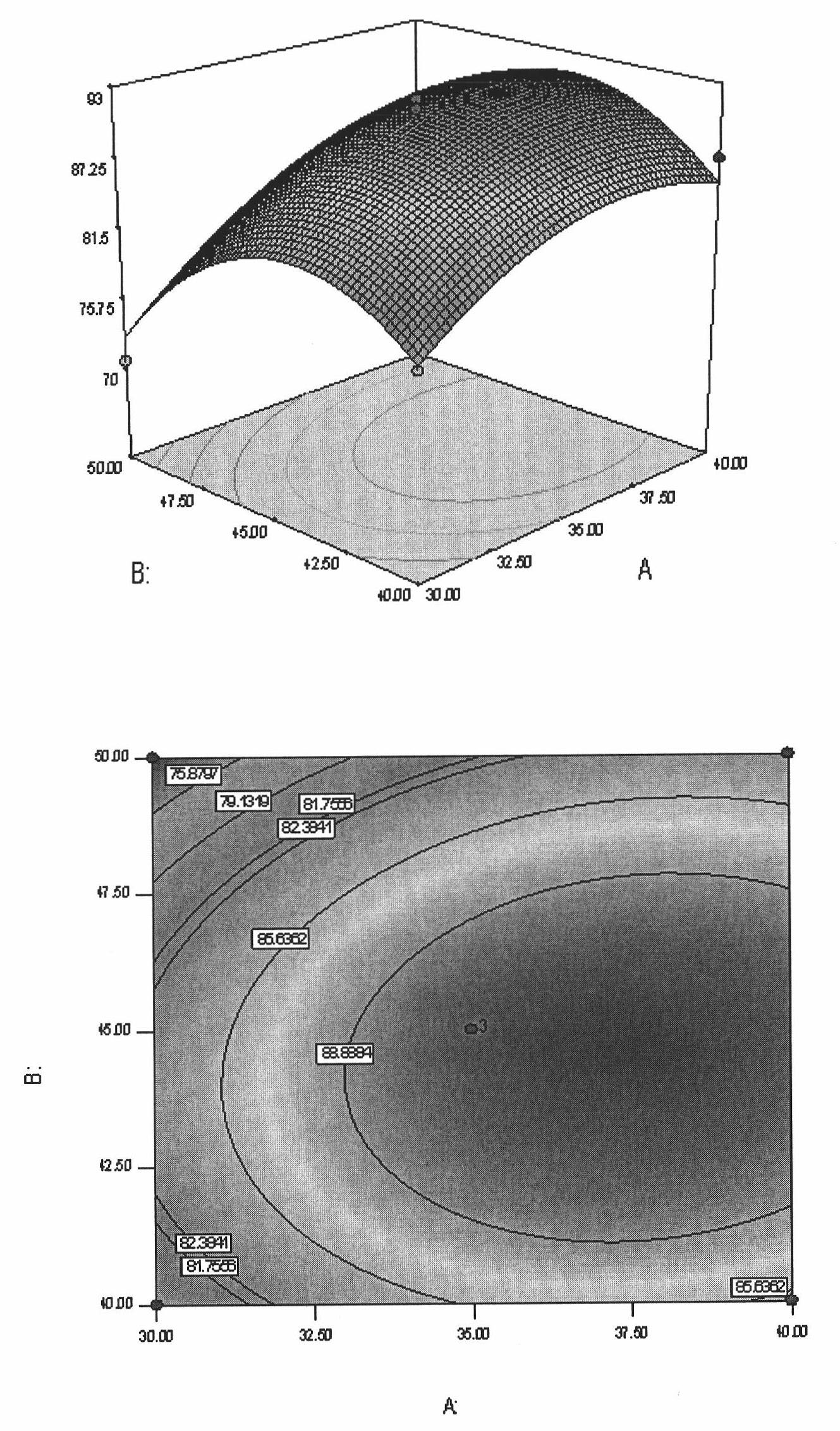

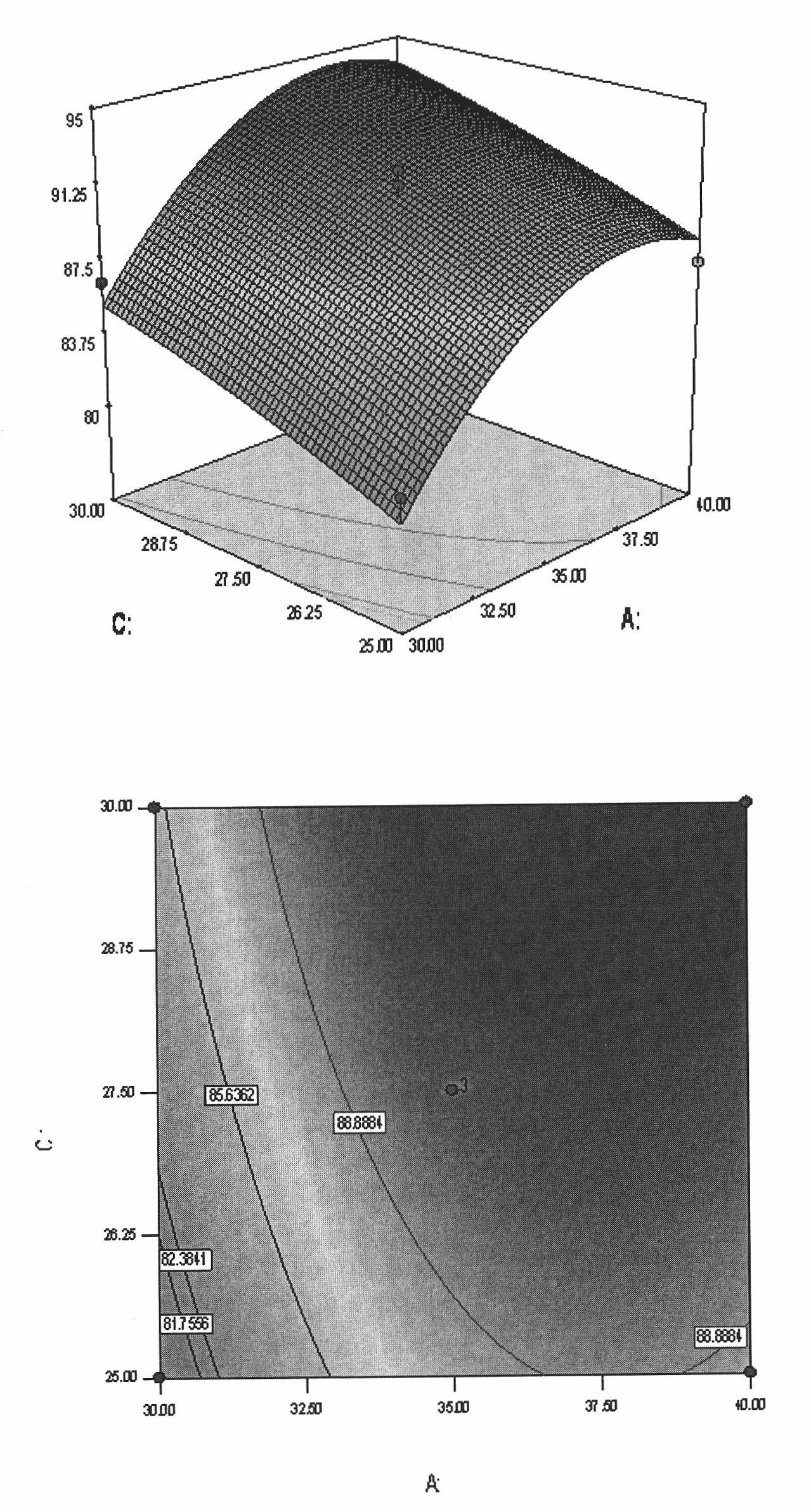

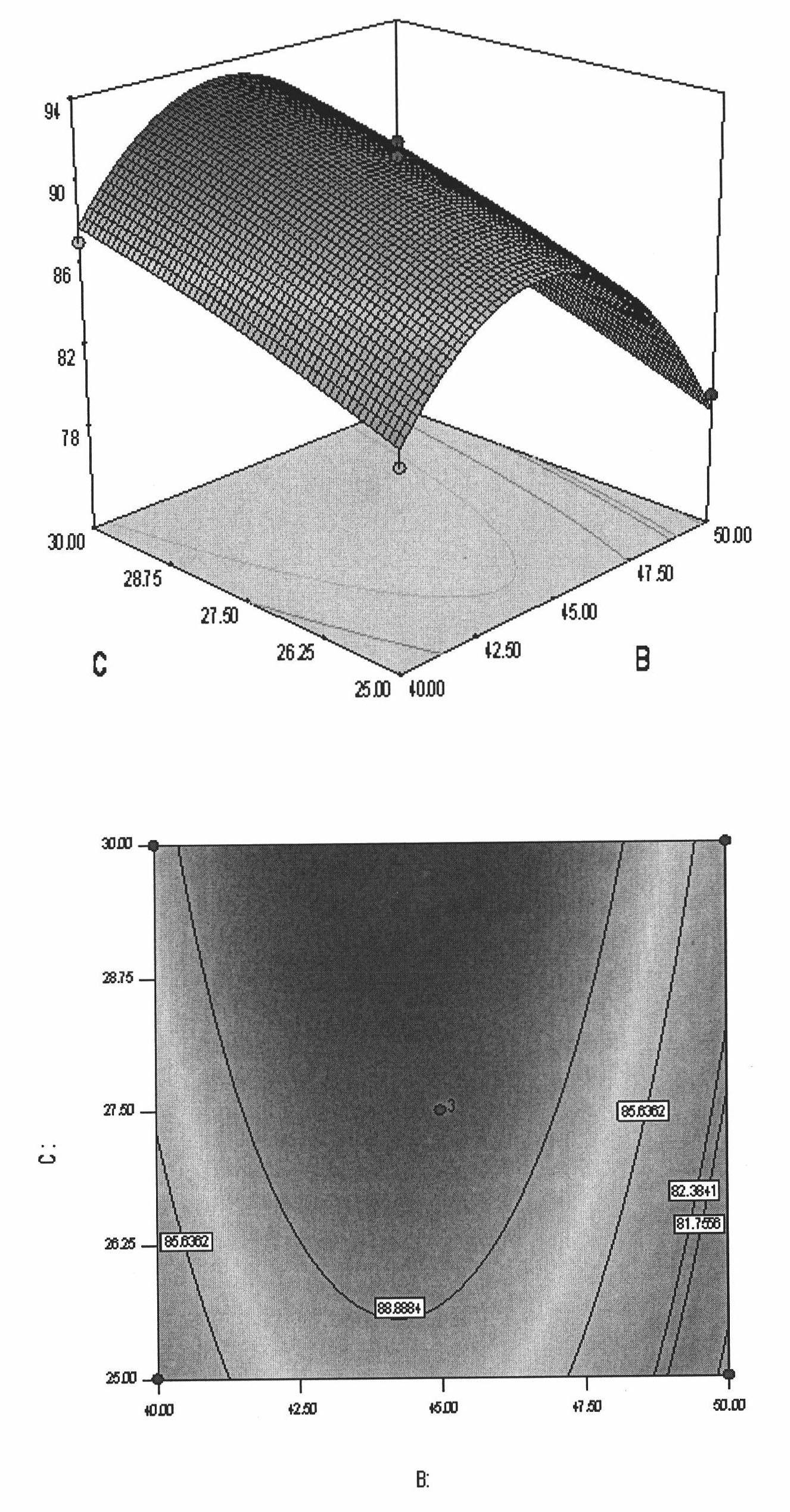

Image

Examples

Embodiment 1

[0051] In step 1, the husked kernels of mature Jatropha curcas seeds are pulverized by a high-speed pulverizer and sieved to a particle size of 10 mesh.

[0052] Step 2, put the Jatropha curcas seed kernel after the above-mentioned pulverization into supercritical CO 2 In the extraction kettle of the extraction device, at an extraction temperature of 40°C and an extraction pressure of 30 MPa, CO 2 Under the condition of a flow rate of 25 L / h, extract for 30 minutes to obtain the extract. During this period, 95% ethanol is added as an entraining agent, and the added amount is 20% of the Jatropha curcas seed kernel by weight.

[0053] Step 3, using the decompression and heating method to separate the extract at a separation pressure of 6.5MPa and a separation temperature of 50°C, supercritical CO 2 The fluid becomes a gas and is recovered.

[0054] Step four, from supercritical CO 2 The extraction liquid is collected in the separation kettle of the extraction device, weighed...

Embodiment 2

[0056] In step 1, the husked kernels of the mature Jatropha curcas seeds are pulverized by a high-speed pulverizer and sieved to a particle size of 40 mesh.

[0057] Step 2, put the Jatropha curcas seed kernel after the above-mentioned pulverization into supercritical CO 2 In the extraction kettle of the extraction device, at an extraction temperature of 50°C and an extraction pressure of 40 MPa, CO 2 Under the condition of a flow rate of 30L / h, extract for 150min to obtain the extract. During this period, 95% ethanol is added as an entraining agent, and the added amount is 100% of the Jatropha curcas kernel by weight.

[0058] Step 3, using the method of decompression and heating to separate the extract under the conditions of separation pressure 7.0MPa and separation temperature 50°C, supercritical CO 2 The fluid becomes a gas and is recovered.

[0059] Step four, from supercritical CO 2 The extraction liquid is collected in the separation kettle of the extraction device...

Embodiment 3

[0061] In step 1, the husked kernels of mature Jatropha curcas seeds are pulverized by a high-speed pulverizer, and sieved, with a particle size of 20 mesh.

[0062] Step 2, put the Jatropha curcas seed kernel after the above-mentioned pulverization into supercritical CO 2 In the extraction kettle of the extraction device, at an extraction temperature of 45°C and an extraction pressure of 35MPa, CO 2 Under the condition of a flow rate of 28 L / h, extract for 90 minutes to obtain the extract. During this period, 95% ethanol is added as an entraining agent, and the added amount is 60% of the Jatropha curcas seed kernel by weight ratio.

[0063] Step 3, using the method of decompression and heating to separate the extract under the conditions of separation pressure 6.8MPa and separation temperature 50°C, supercritical CO 2 The fluid becomes a gas and is recovered.

[0064] Step four, from supercritical CO 2 The extraction liquid is collected in the separation kettle of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com