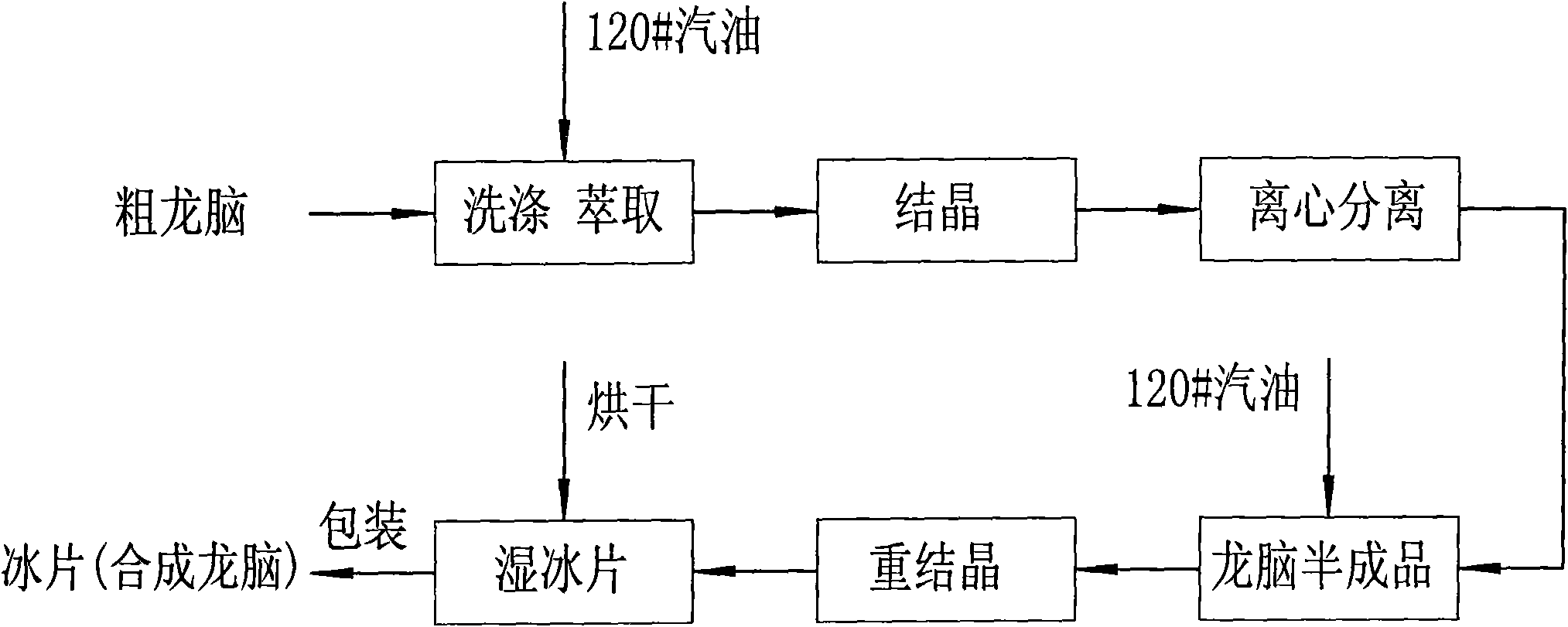

Method for separating borneol by using separation kettle with stirrer of supercritical CO2 fluid extraction system

A separation kettle and supercritical technology, applied in the separation/purification of hydroxyl compounds, bulk chemical production, organic chemistry, etc., can solve the problems of large production field occupation, hidden danger of borneol safety, low efficiency, etc. The effect of short purification time and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

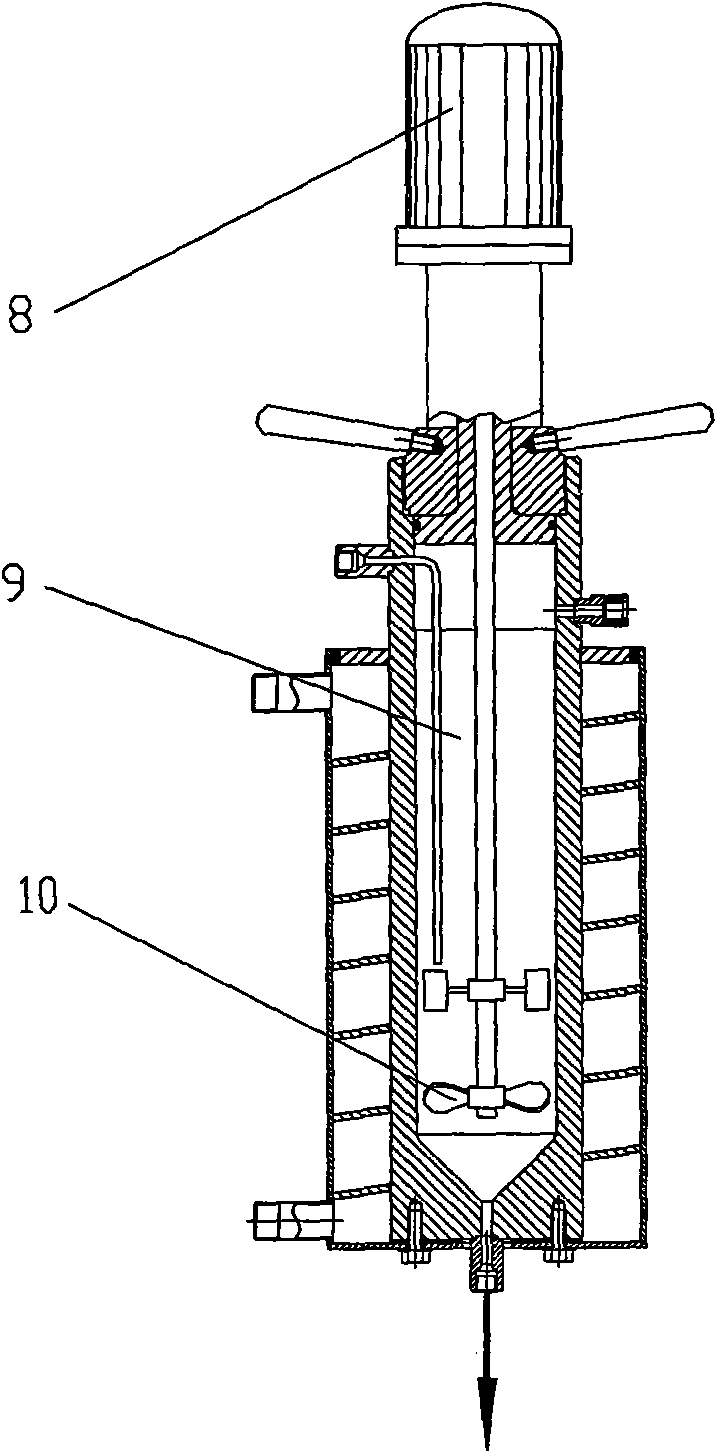

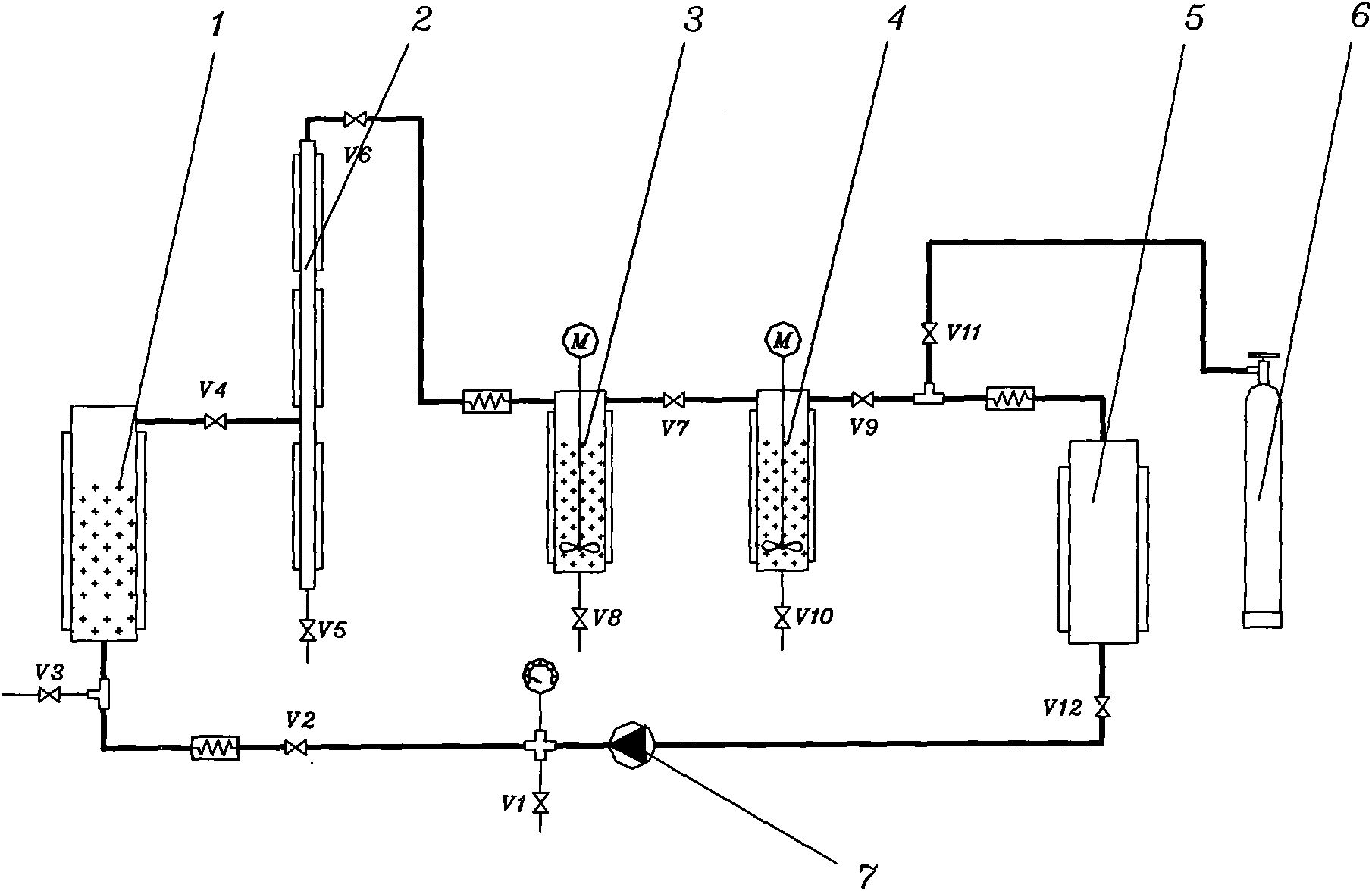

Method used

Image

Examples

Embodiment 1

[0031] (1) Weighing a certain batch of thick borneol 250g, its orthoborneol content is 44%, directly this borneol is put into extraction kettle 1, pressurizes CO by high-pressure pump 7 2 The fluid passes through the heat exchanger to make CO 2 The fluid becomes subcritical fluid and enters the extraction kettle 1 from the bottom of the extraction kettle for extraction, and the extraction condition is extraction pressure 16MP a , the extraction temperature is 25°C.

[0032] (2) The fluid containing orthoborneol and other components extracted by the extraction kettle enters the middle part of the separation column 2, and performs first-stage separation in the separation column. Separation column pressure 10MP a , temperature 5°C;

[0033] (3) the fluid that has concentrated orthoborneol through the first-stage separation column 1 enters the separation kettle 3 again, and carries out second-stage separation in the separation kettle, and the separation kettle pressure is 7MP ...

Embodiment 2

[0037](1) weighing a certain batch of thick borneol 250g, its orthoborneol weight content is 44%, directly this borneol enters in the extraction kettle 1, is pressurized by high-pressure pump 7 and CO 2 The fluid passes through the heat exchanger to make CO 2 The fluid becomes supercritical fluid and enters the extraction kettle 1 from the bottom of the extraction kettle for extraction, and the extraction condition is extraction pressure 30MP a , The extraction temperature is 45°C.

[0038] (2) The fluid containing orthoborneol and other components extracted by the extraction kettle enters the middle part of the separation column 2, and performs first-stage separation in the separation column. Separation column pressure 16MP a , temperature 35°C;

[0039] (3) The fluid that has concentrated orthoborneol through the first-stage separation column 1 enters the separation kettle 3 again, and carries out second-stage separation in the separation kettle, and the separation kettle...

Embodiment 3

[0043] (1) weighing a certain batch of thick borneol 250g, its orthoborneol content is 44%, directly enters in the extraction kettle 1, is pressurized by the high-pressure pump 7 and CO 2 The fluid passes through the heat exchanger to make CO 2 The fluid becomes supercritical fluid and enters the extraction kettle 1 from the bottom of the extraction kettle for extraction, and the extraction condition is extraction pressure 30MP a , The extraction temperature is 45°C.

[0044] (2) The fluid containing orthoborneol and other components extracted by the extraction kettle enters the middle part of the separation column 2, and performs first-stage separation in the separation column. Separation column pressure 16MP a , temperature 35°C;

[0045] (3) The fluid that has concentrated orthoborneol through the first-stage separation column 1 enters the separation kettle 3 again, and carries out second-stage separation in the separation kettle, and the separation kettle pressure is 9M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com