Method for suspending or re-suspending particles in a solution and apparatus adapted thereto

A particle suspension and resuspension technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as sticking to magnets, poor suspension and re-sedimentation of particles, and poor purification results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The embodiments shown in the figures are not drawn true to scale, but merely support illustrations of corresponding embodiments. Wherein individual features may be illustrated on a larger or smaller scale. In the figures, identical elements are provided with identical reference numerals.

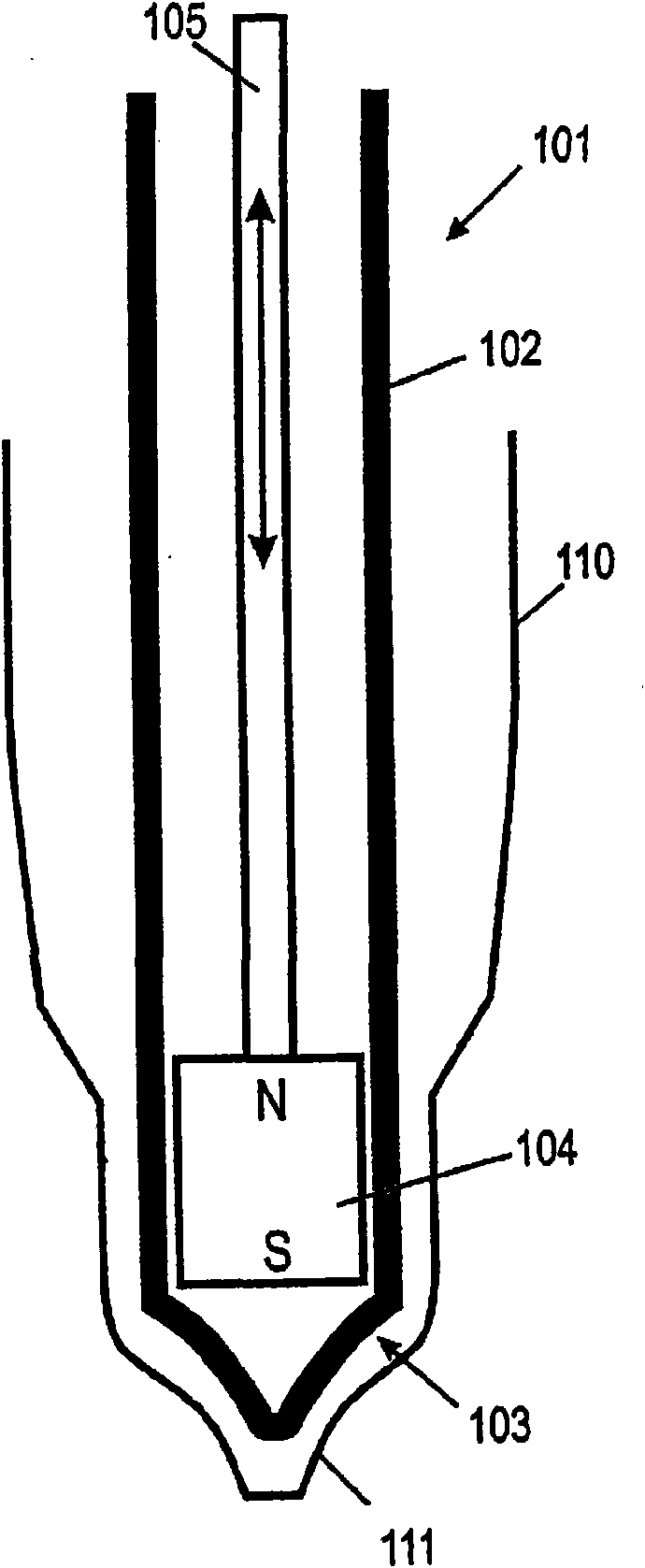

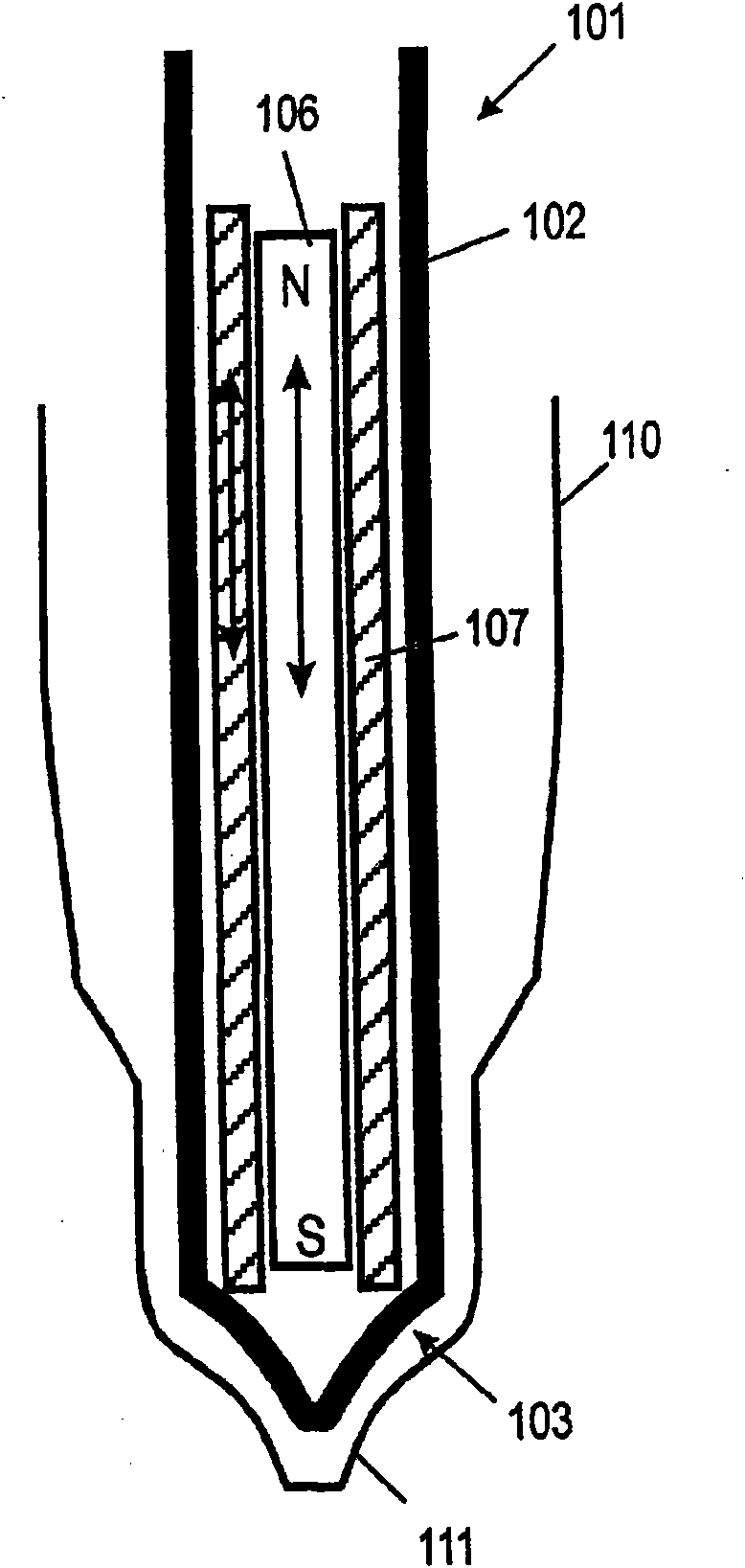

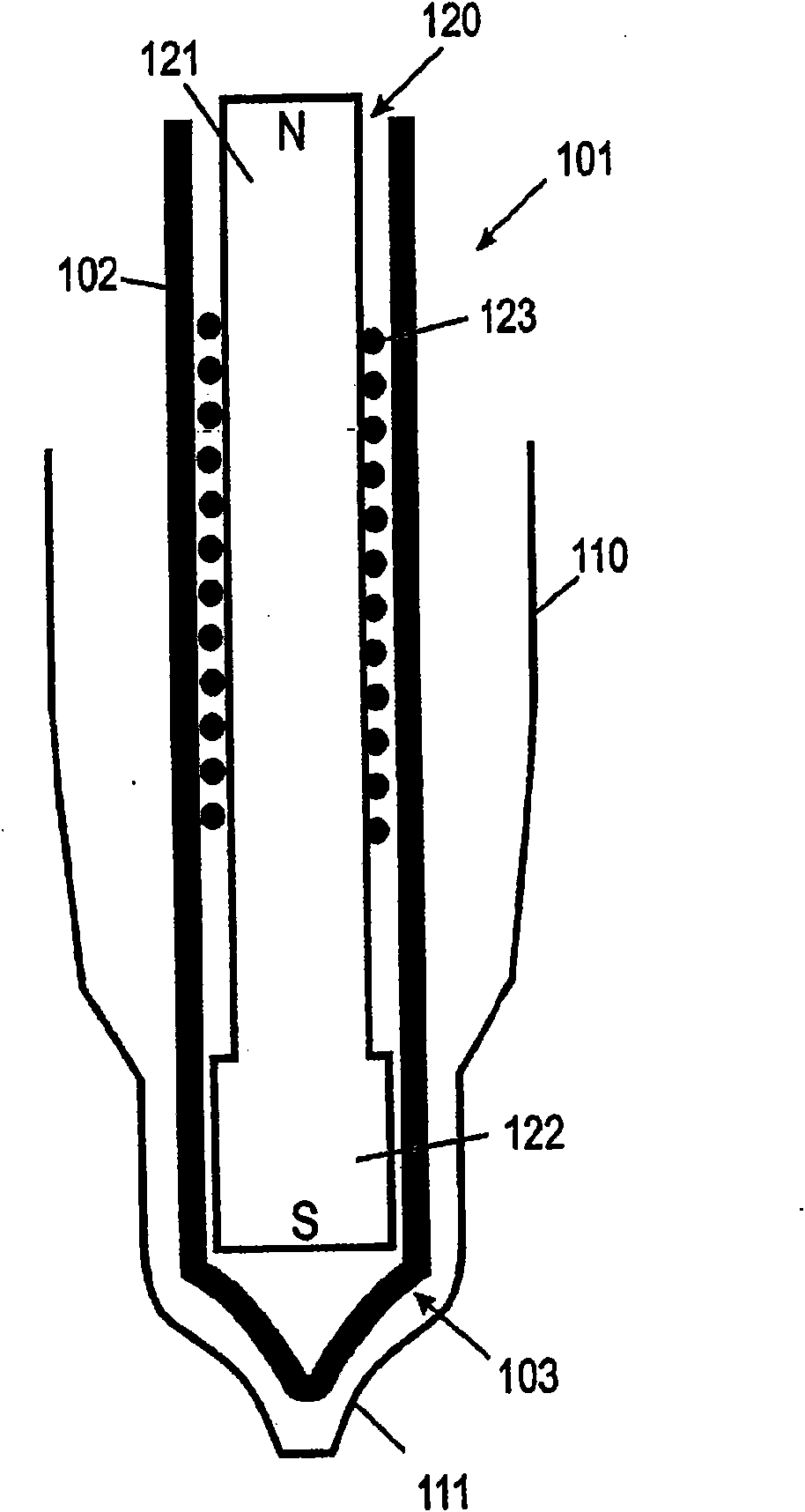

[0071] Figure 1A A first embodiment of a mixing rod 101 is shown. The mixing rod can, for example, have an elongated cylindrical shape. The mixing rod 101 has, for example, a cylindrical or rotationally symmetrical housing 102 which generally consists of a non-magnetic material. Preferably the material of the shell 102 should be chosen such that it does not weaken the magnetic field or only slightly weakens it. For example, the shell 102 may consist of, for example, a largely dimensionally stable inert synthetic material. In order to achieve dimensional stability, the thickness of the material of the shell 102 may be appropriately selected. The shell may also be reinforced by, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com