Method and device for realizing laser focusing

An implementation method and laser technology, which are applied in the directions of laser welding equipment, optics, optical components, etc., to achieve the effect of smaller gradient and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

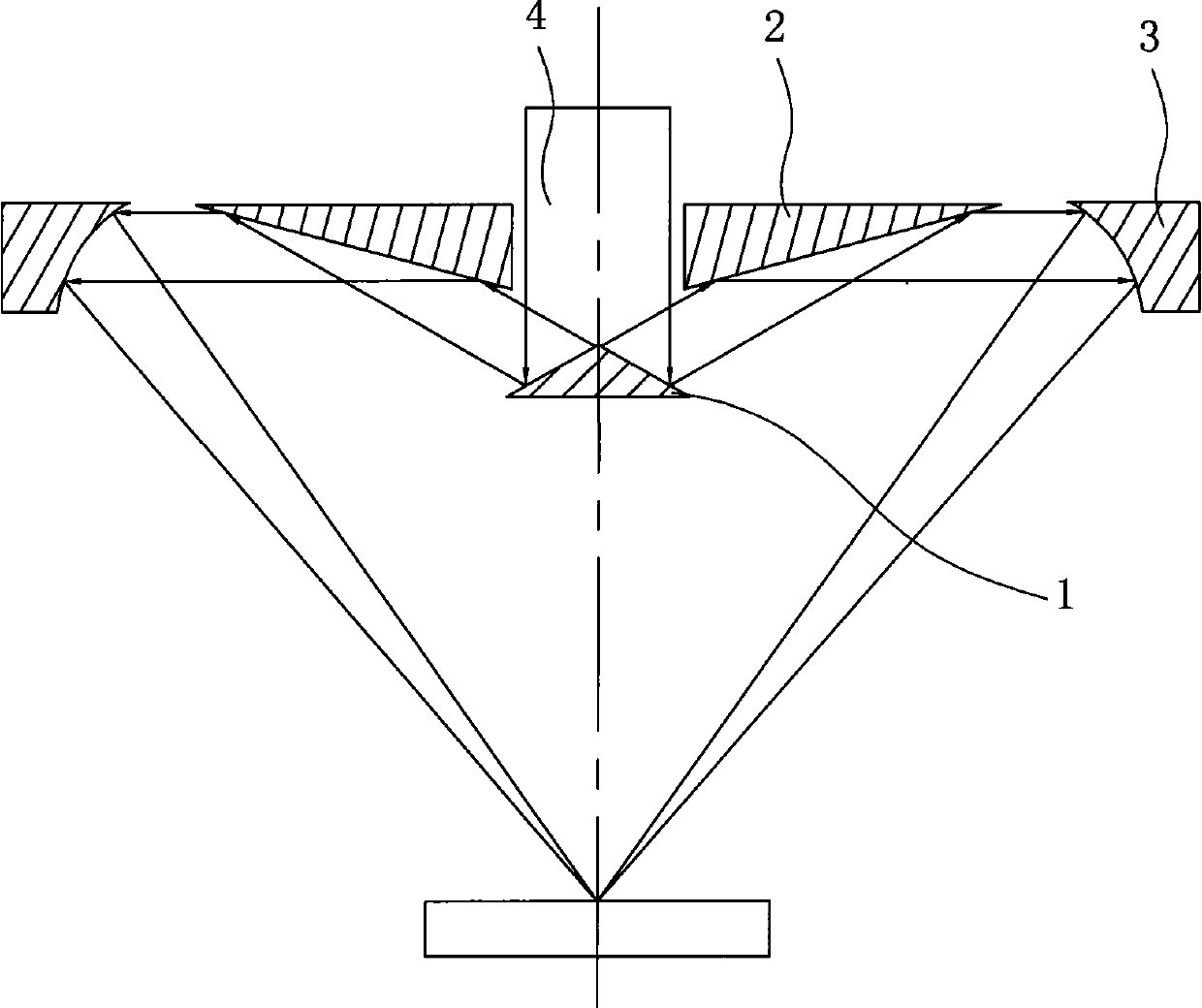

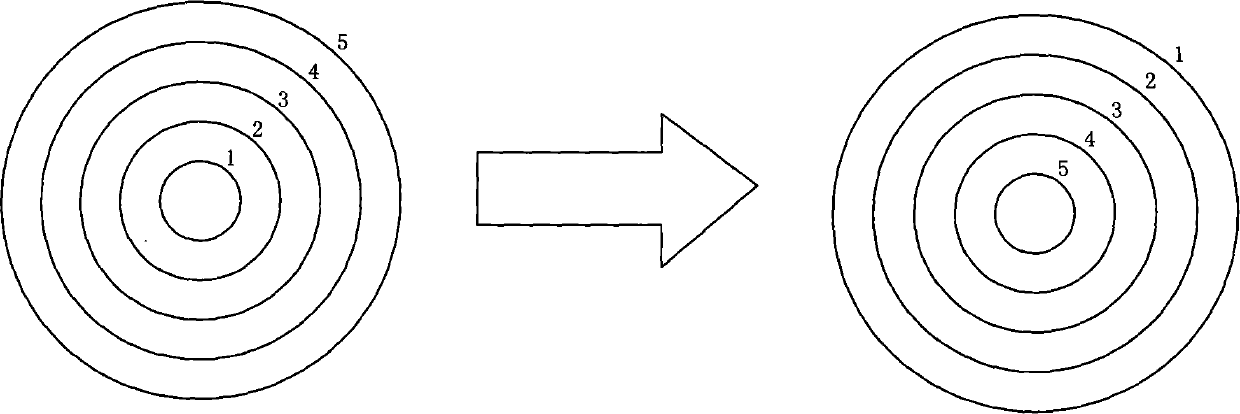

[0028] Embodiment 1: A method for realizing laser focusing, using the principle of reflection and focusing of mirrors and focusing mirrors, the spot of the laser beam is exchanged and focused in the radial direction in units of rings, including the following steps:

[0029] (1) Reflect the laser beam into an inverted conical ring beam;

[0030] (2) Transform the inverted conical ring beam into a ring beam;

[0031] (3) Focusing the annular light beam to form an annular cone-shaped beam, and forming a conical hollow light-free zone in the middle of the annular cone-shaped beam to obtain a focused spot of hollow annular light.

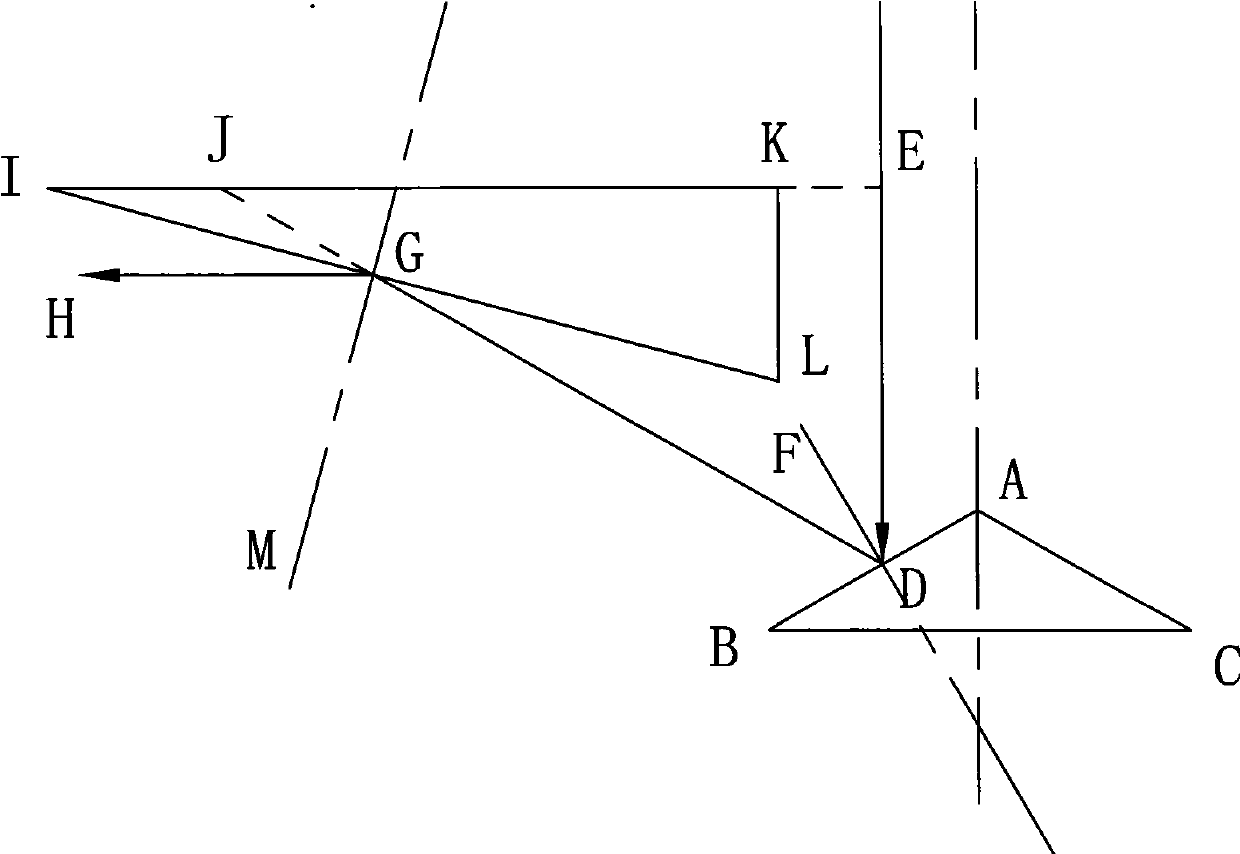

[0032] see figure 1 As shown, a laser focusing device includes a first conical reflector 1 and a parabolic reflector 3 arranged in parallel, and a second conical reflector 2 is arranged on the coaxial inside of the parabolic reflector 3. The conical reflector 2 is opposite to the apex of the first conical reflector 1 and the bottom surfaces are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com