Gear shift assistor of vehicle

A technology for power assist devices and vehicles, which is applied to transmission control, components with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

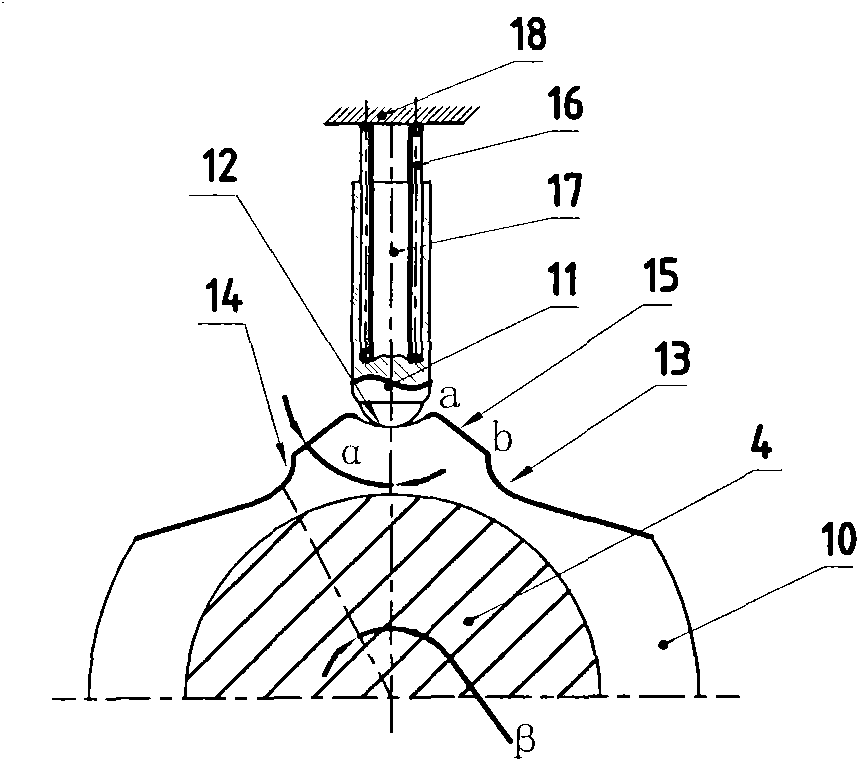

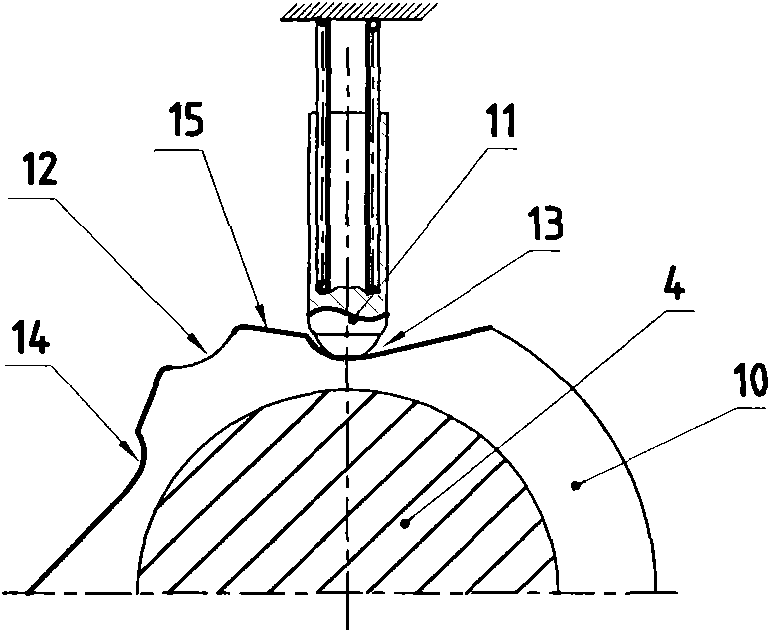

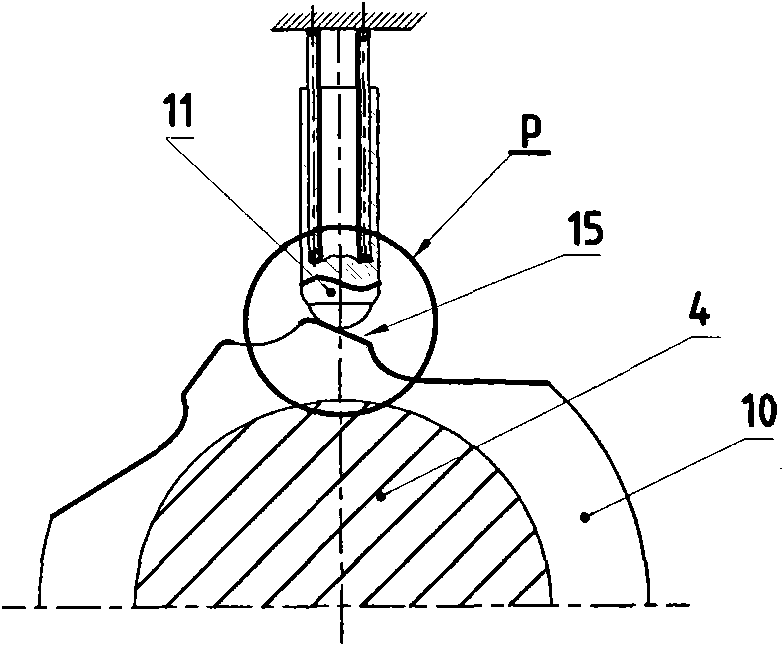

[0019] see Figure 1 to Figure 4 , the vehicle gear shift assisting device of the present invention includes a shift self-locking block 10 arranged on the shift shaft 4, and a spring self-locking pin 11 for locking the shift self-locking block, and the shift self-locking block 10 protrudes On the circumference of the shift shaft 4, the shift self-locking block 10 is respectively provided with an arc-shaped groove 12 for a neutral gear position, an arc-shaped groove 13 for a forward gear position and an arc-shaped groove 14 for a backward gear position. There is a shift stroke section 15 respectively between the arc-shaped groove 12 of the neutral gear position, the arc-shaped groove 13 of the forward gear position, and the arc-shaped groove 14 of the backward gear position, and the two shift stroke sections 15 are all arranged The slope of the shift stroke section 15 is a straight slope, and the distance between the starting point a of each shift stroke section 15 and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com