Pressure grouting device for overall length spiral anchor rod and construction process

A technology of grouting device and screw anchor, which is used in the installation of anchor rods, infrastructure engineering, sheet pile walls, etc. problems, to achieve the effect of convenient grouting time, material saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

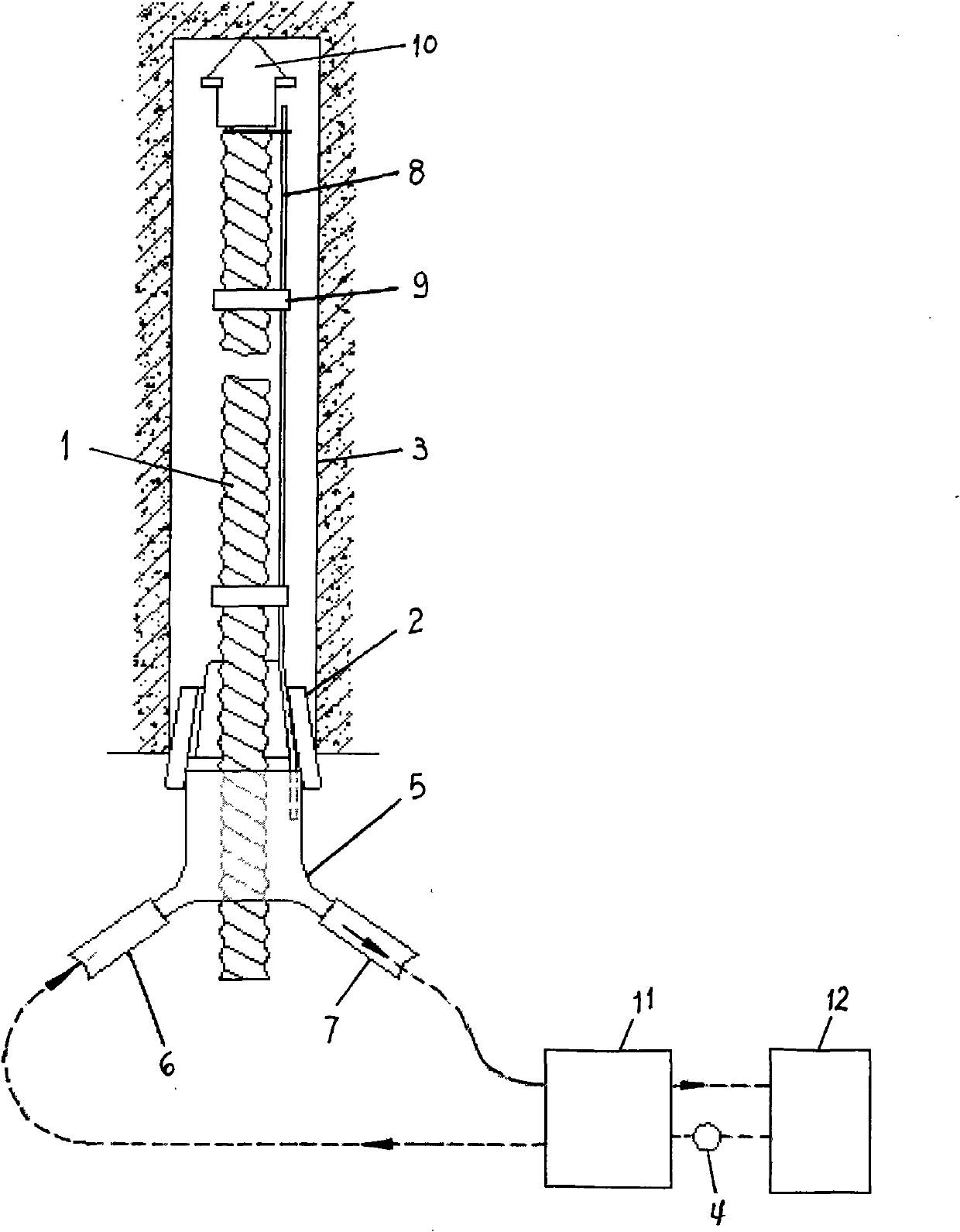

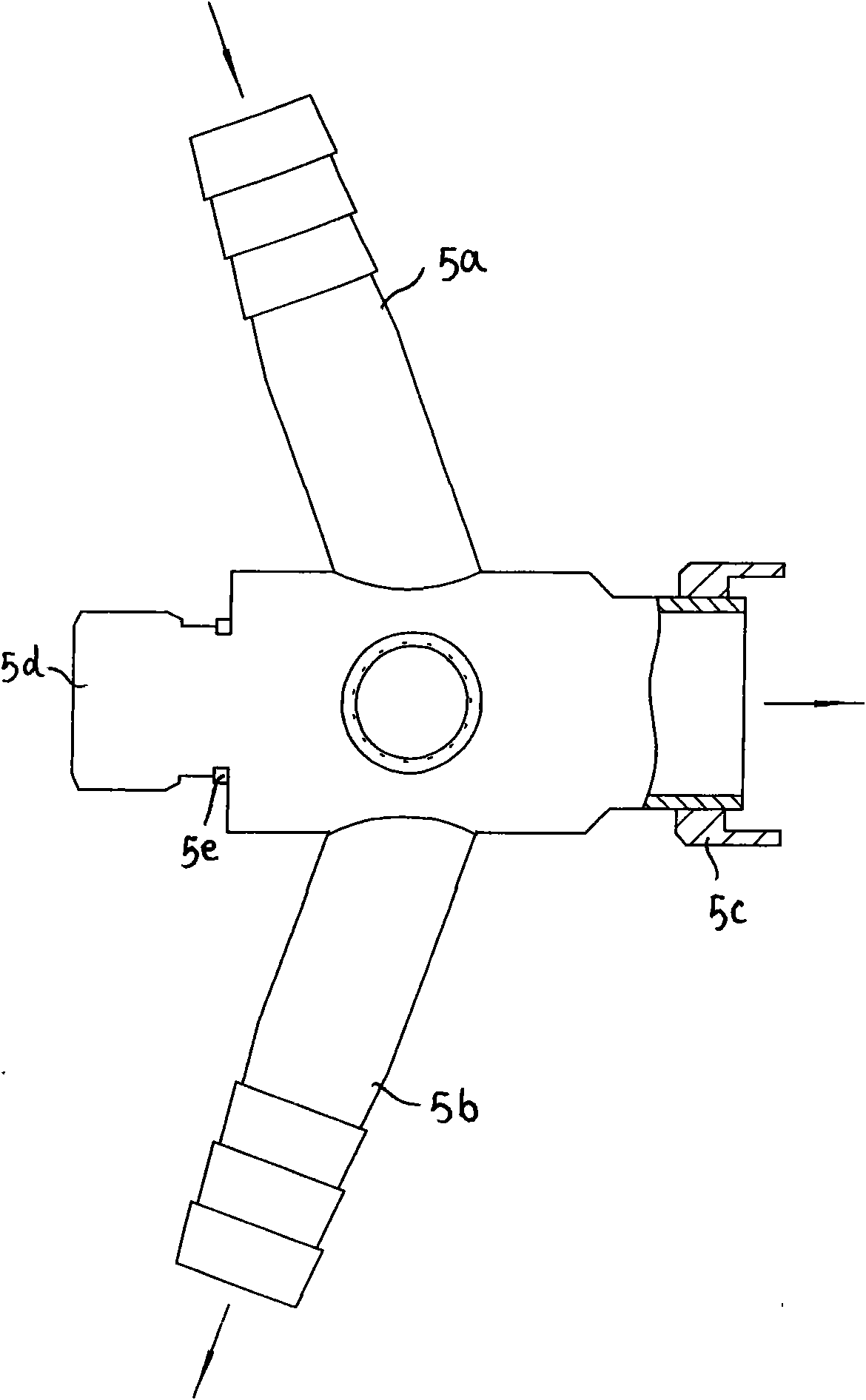

[0031] figure 1 figure 2 As shown, the present invention includes a grouting machine 12, a full-length helical anchor body 1, and an anchor head 10 is screwed to the front end of the full-length helical anchor 1; see Figure 5 , also has a pressure grout plug 2 located at the rear of the full-length helical anchor body 1 and used to block the anchor hole 3: it is composed of a nylon inner plug 21 in the shape of a cone and a rubber outer plug 22, and the nylon inner plug is screwed On the full-length screw bolt body 1, pressure grouting holes 21a are evenly distributed on the nylon inner plug, and the rubber outer plug is nested on the nylon inner plug; The pipe joint 5b is symmetrically welded on the straight pipe and communicates with each other. The angle between the grouting pipe joint and the straight pipe in the grouting direction is an obtuse angle. It is crimped on the front end of the straight pipe, and the rear end of the straight pipe is screwed with a gland 5d, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com