Water-based solid lubricant

A lubricant and water-based technology, which is applied in the field of water-based solid lubricants, can solve the problems of high toxicity, wear resistance, and volatility, and achieve the effects of strong adhesion, wide environmental temperature range, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

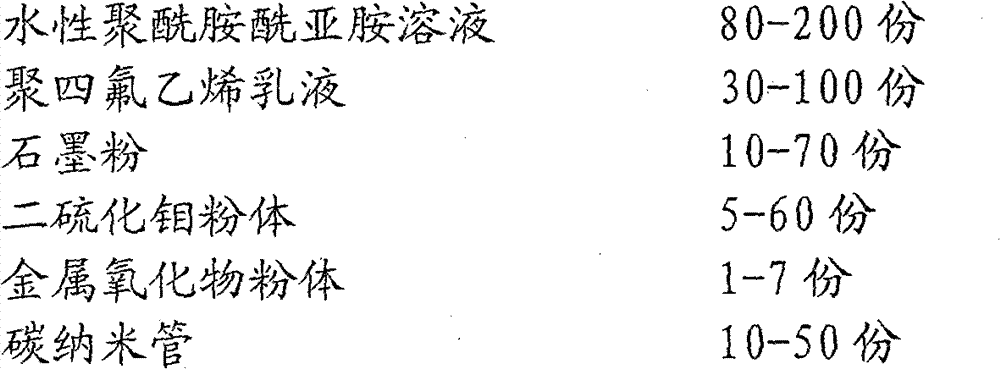

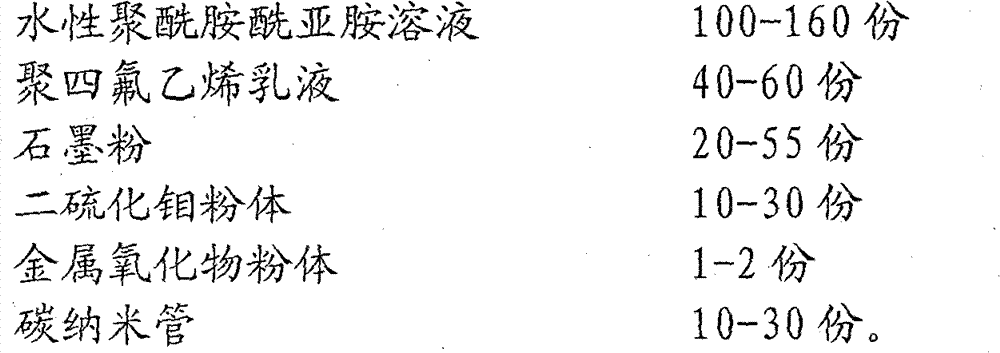

Method used

Image

Examples

Embodiment 1

[0027] An aqueous dispersion solid lubricant, the weight ratio of its raw materials is: 100 g of aqueous polyamideimide solution, 30 g of polytetrafluoroethylene emulsion, 20 g of graphite powder, 5 g of molybdenum disulfide powder, 1 g of zinc oxide powder, 1 g of carbon 10 g of nanotubes, wherein graphite powder, molybdenum disulfide powder, and zinc oxide powder are all 1 micron in fineness; carbon nanotubes are industrial-grade single-walled carbon nanotubes; the water-based polyamideimide solution is commercially available The aqueous solution with a solid content of 25-35%; the polytetrafluoroethylene emulsion is a commercially available aqueous solution with a solid content of 55-65%.

[0028] The preparation method is as follows: the water-based polyamideimide solution and the polytetrafluoroethylene emulsion are mixed at a high speed of 500 rpm according to the above-mentioned dosage, and then dispersed in the mixed solution in sequence according to the proportion of t...

Embodiment 2

[0031] An aqueous dispersion solid lubricant, the weight ratio of its raw materials is: 200 g of aqueous polyamideimide solution, 100 g of polytetrafluoroethylene emulsion, 70 g of graphite powder, 40 g of molybdenum disulfide powder, 1 g of zinc oxide powder, 1 g of carbon 10g of nanotubes, wherein the fineness of graphite powder, molybdenum disulfide powder and zinc oxide powder are all 1 micron. The carbon nanotubes are industrial grade single-walled carbon nanotubes; the aqueous polyamideimide solution is a commercially available aqueous solution with a solid content of 25-35%; the polytetrafluoroethylene emulsion is a commercially available solution with a solid content of 55-65% aqueous solution.

[0032] The preparation method is as follows: mixing the aqueous polyamideimide solution and the polytetrafluoroethylene emulsion according to the above-mentioned dosage under high-speed stirring at a speed of 400 rpm, and then dispersing the graphite powder in the mixed soluti...

Embodiment 3

[0035] An aqueous dispersion solid lubricant, the weight ratio of its raw materials is: 150 g of aqueous polyamide-imide solution, 40 g of polytetrafluoroethylene emulsion, 30 g of graphite powder, 60 g of molybdenum disulfide powder, 1 g of zinc oxide powder, and 1 g of carbon dioxide. Nanotubes are 30g, of which graphite powder, molybdenum disulfide powder and zinc oxide powder are all 1 micron in fineness. The carbon nanotubes are industrial grade single-walled carbon nanotubes; the aqueous polyamideimide solution is a commercially available aqueous solution with a solid content of 25-35%; the polytetrafluoroethylene emulsion is a commercially available solution with a solid content of 55-65% aqueous solution.

[0036] The preparation method is as follows: mixing the aqueous polyamideimide solution and the polytetrafluoroethylene emulsion according to the above-mentioned dosage under high-speed stirring at a speed of 300 rpm, and then dispersing the graphite powder in the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com