Cement asphalt mortar material with low elastic modulus

A low-elastic-modulus, cement-asphalt technology, applied in the field of building materials, can solve the problems of difficulty in improving the shock absorption performance, environmental pollution, waste, etc., and achieve high bond strength, good shock absorption performance, and improved The effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The mass ratio of each component is as follows:

[0029] Cement: 1, emulsified asphalt: 0.45, sand: 1.3, water reducer: 0.0013, water: 0.55, aluminum powder: 0.0001, expansion agent: 0.32, defoamer: 0.0045, air-entraining agent: 0.00025, rubber particles: 0.16.

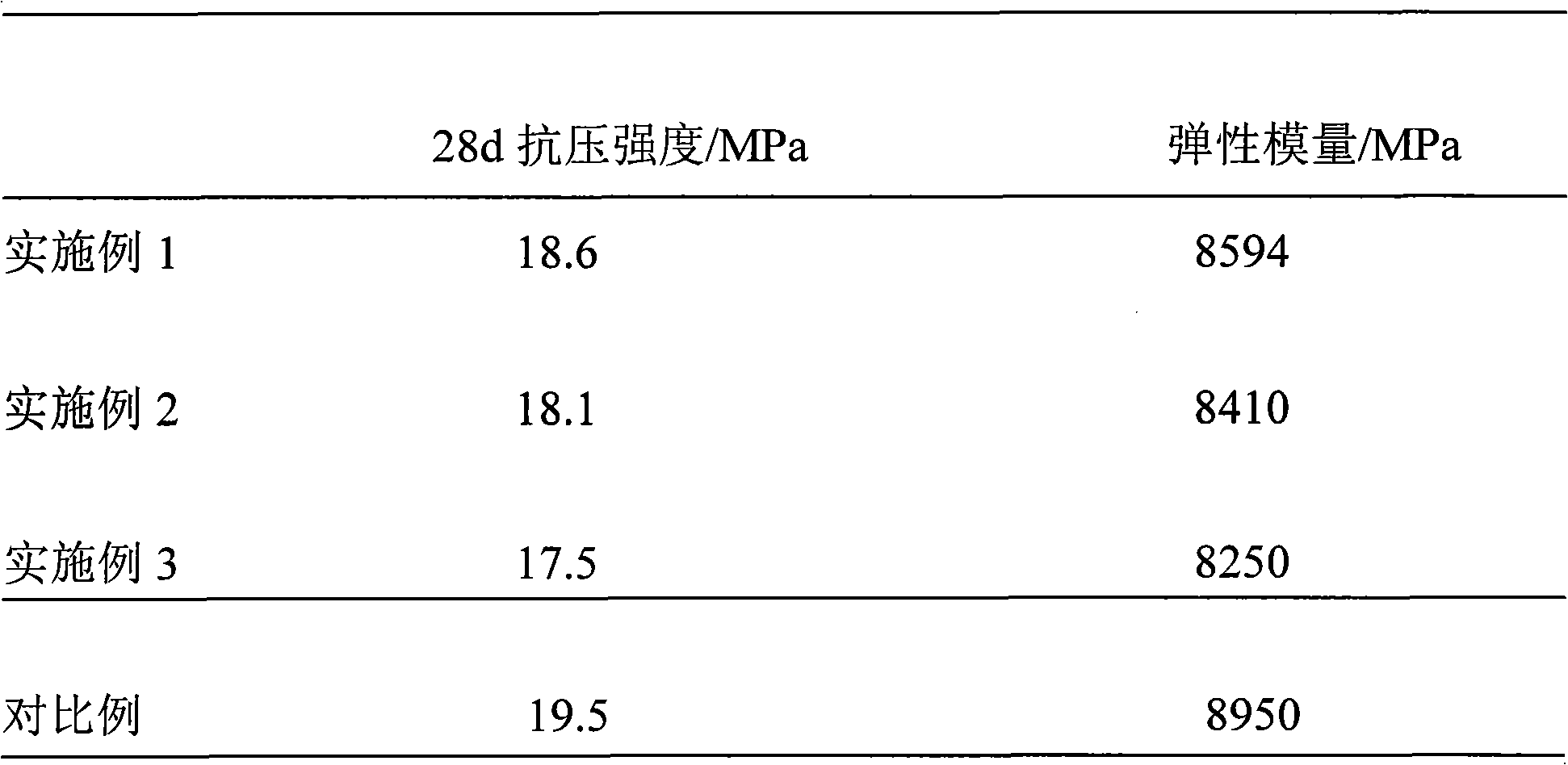

[0030] Accurately weigh various components according to the above mixing ratio, first weigh the solid raw materials in proportion, put them together in a mixer and stir for 30 seconds, then add emulsified asphalt and water and stir for another 120 seconds. The performance test was carried out on the prepared CA mortar material. The test results are shown in Table 1.

Embodiment 2

[0032] The mass ratio of each component is as follows:

[0033] Cement: 1, emulsified asphalt: 0.45, sand: 1.3, water reducer: 0.0013, water: 0.55, aluminum powder: 0.0001, expansion agent: 0.32, defoamer: 0.0045, air-entraining agent: 0.00025, rubber particles: 0.24.

[0034] Accurately weigh various components according to the above mixing ratio, first weigh the solid raw materials in proportion, put them together in a mixer and stir for 30 seconds, then add emulsified asphalt and water and stir for another 120 seconds. The performance test was carried out on the prepared CA mortar material. The test structure is shown in Table 1.

Embodiment 3

[0036] The mass ratio of each component is as follows:

[0037] Cement: 1, emulsified asphalt: 0.45, sand: 1.3, water reducer: 0.0013, water: 0.55, aluminum powder: 0.0001, expansion agent: 0.32, defoamer: 0.0045, air-entraining agent: 0.00025, rubber particles: 0.32.

[0038] Accurately weigh various components according to the above mixing ratio, first weigh the solid raw materials in proportion, put them together in a mixer and stir for 30 seconds, then add emulsified asphalt and water and stir for another 120 seconds. The performance test was carried out on the prepared CA mortar material. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com