Full-automatic high-speed winder

A winder, fully automatic technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., to achieve high work efficiency and economic efficiency, accurate measurement, and compact volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

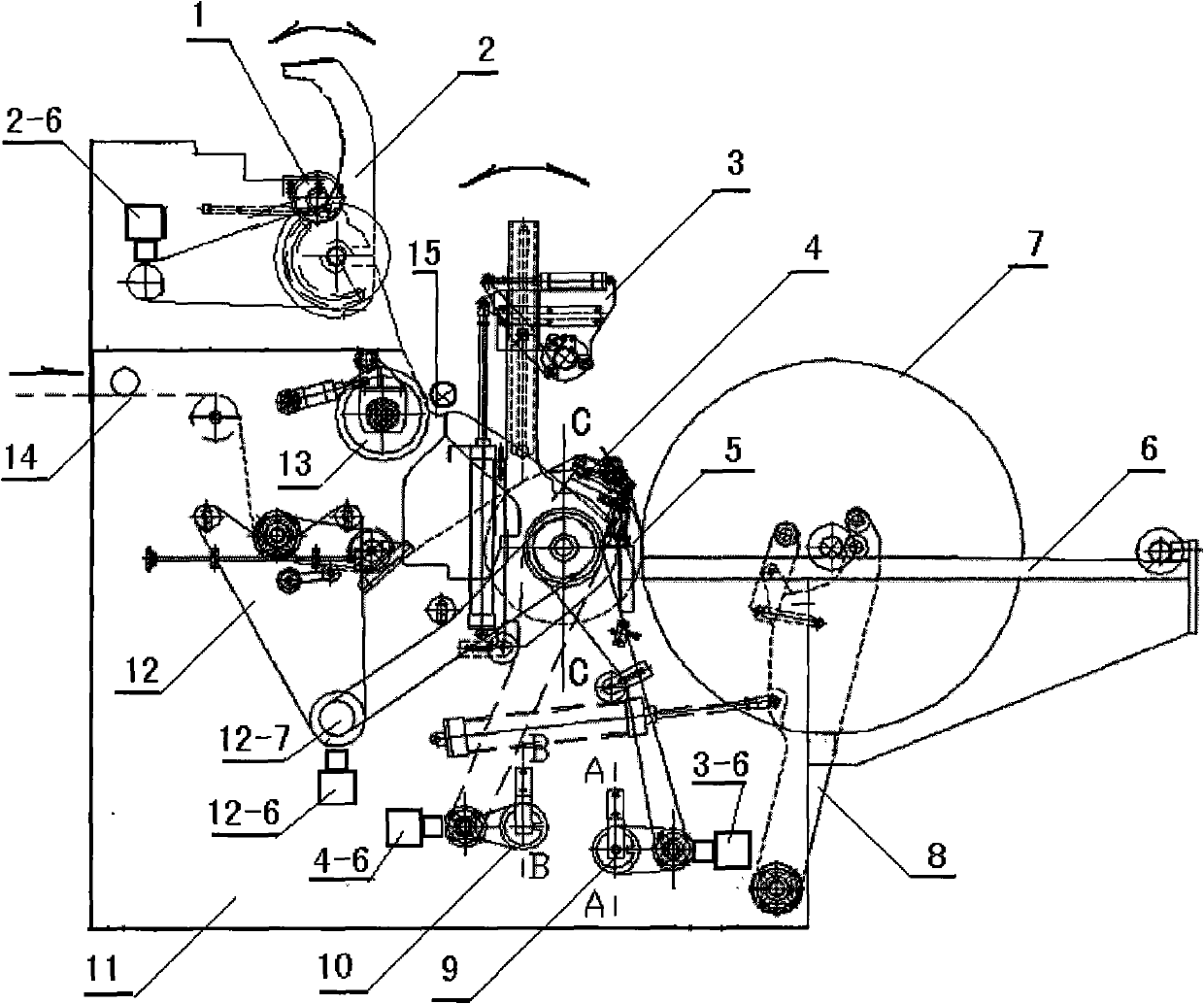

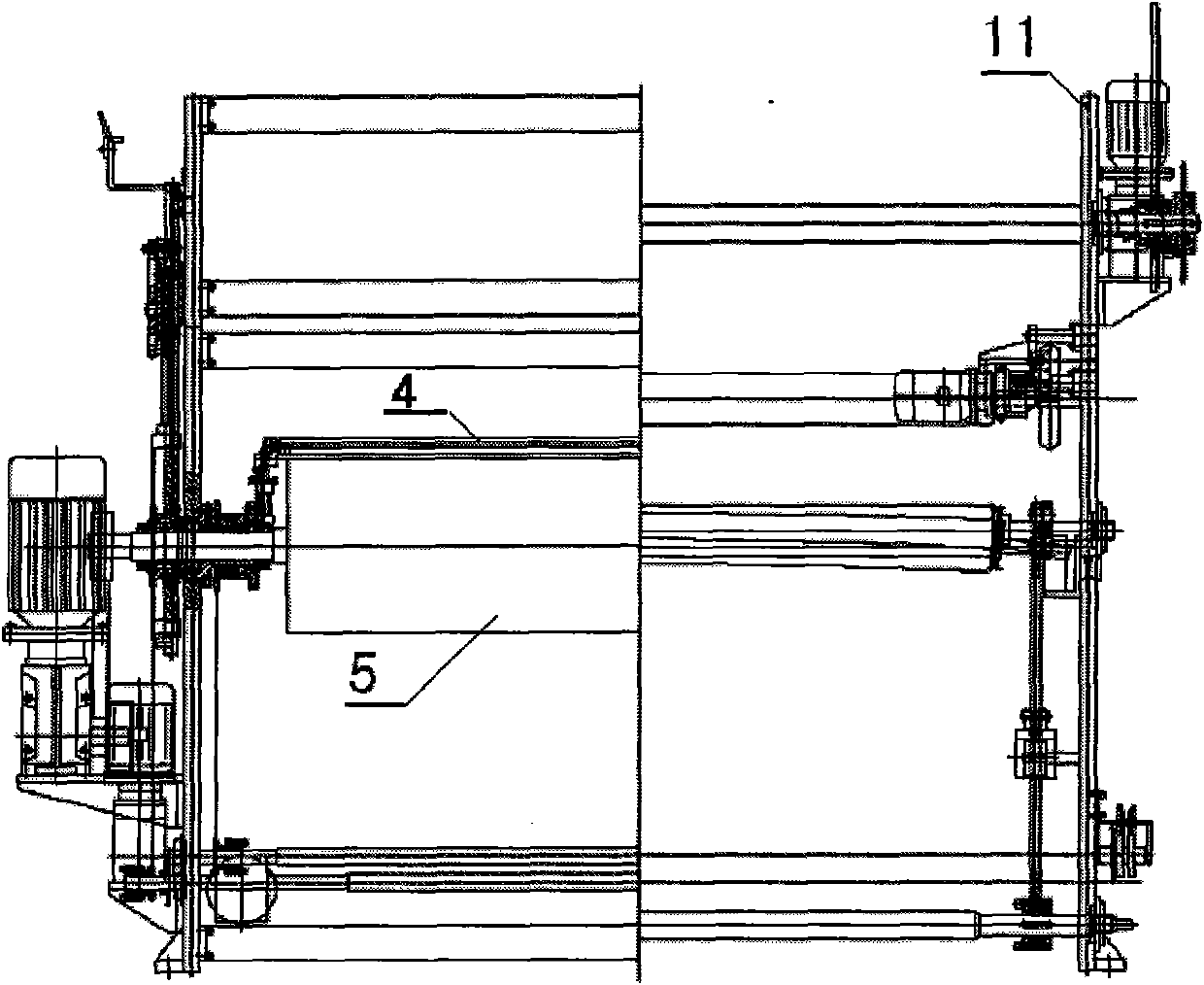

[0053] See attached figure 1 And attached figure 2 , The fully automatic high-speed winder of the present invention includes a frame 11, a shaft changing device, a traction device, a cross-cutting device 4 and an automatic control device.

[0054] Described frame 11 comprises the upright wallboard of left and right sides, and is processed with some pairs of bearing holes on two wallboards of left and right sides for installing some traction rollers, and pushing material parallel support 6 is connected with it.

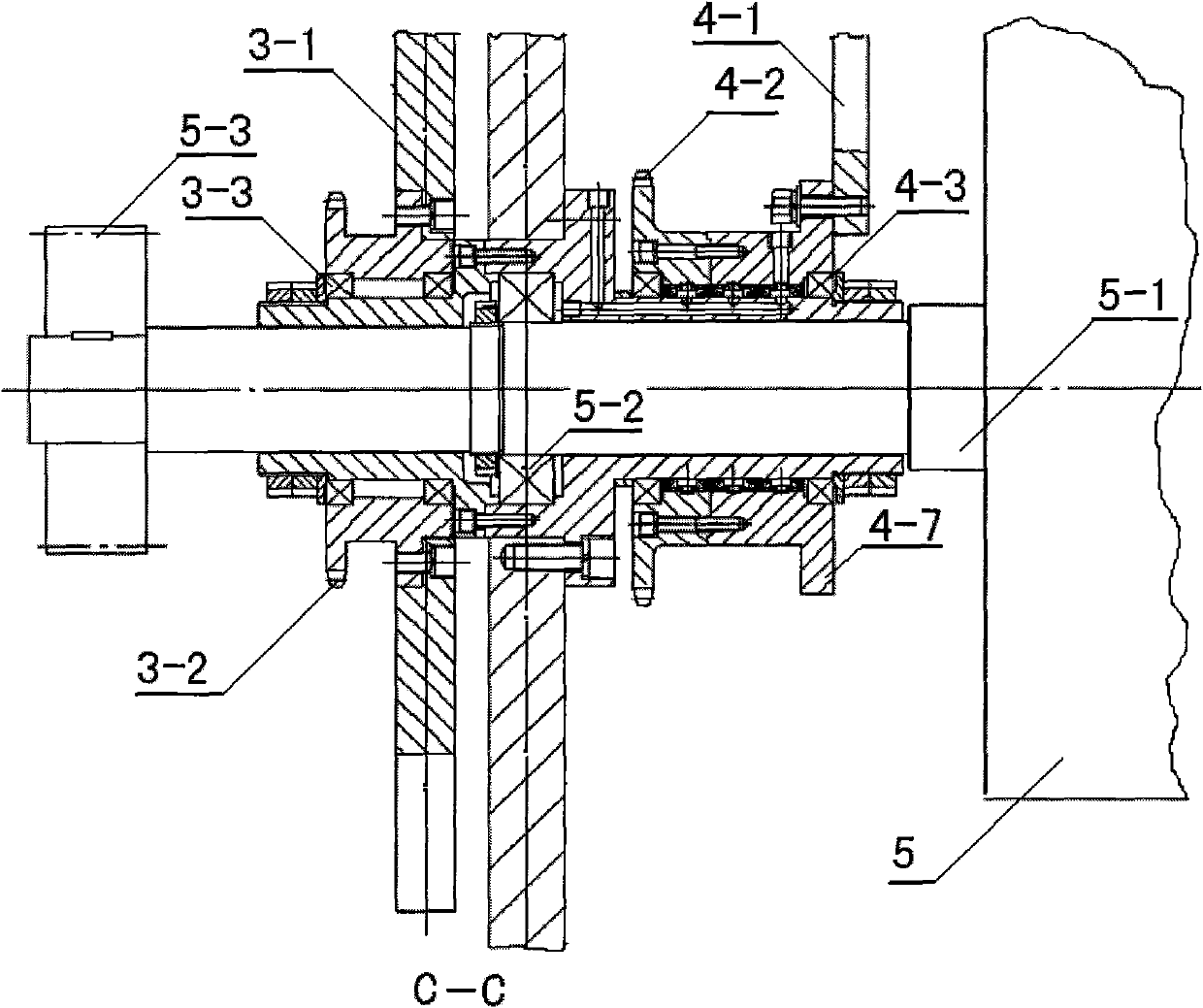

[0055] The shaft changing device includes a shaft-releasing mechanism 2, a speed-increasing mechanism 13, and a final shaft mechanism 3, and the three are installed sequentially along the wallboard from top to bottom.

[0056] see Figure 16 1. Shaft release mechanism 2 is a pair of hook-shaped brackets that rotate synchronously, referred to as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com