Method of and device for connecting metal bands

一种金属带、夹紧装置的技术,应用在金属加工、金属轧制、金属轧制等方向,能够解决抗弯刚度剥裂等问题,达到减少强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

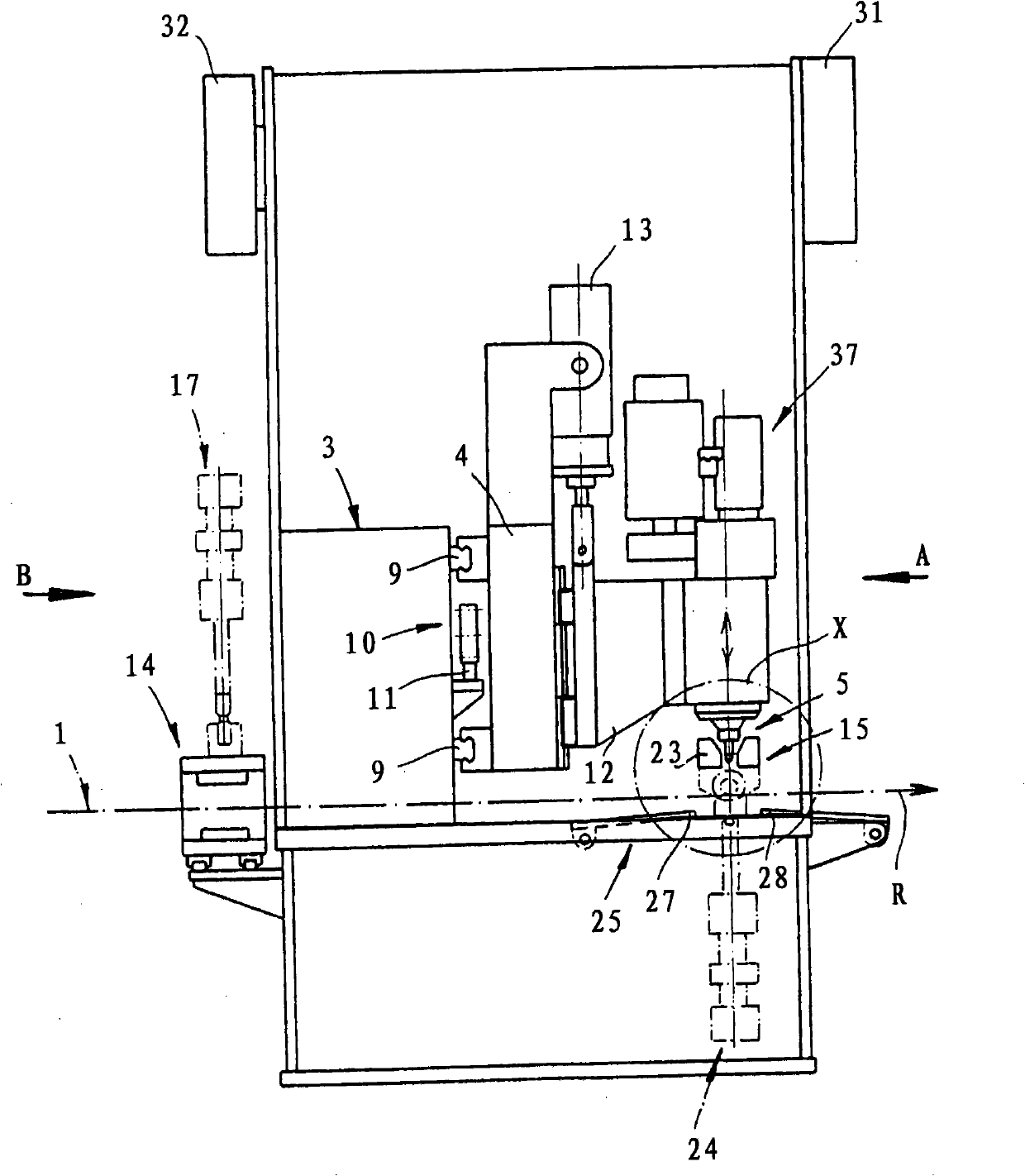

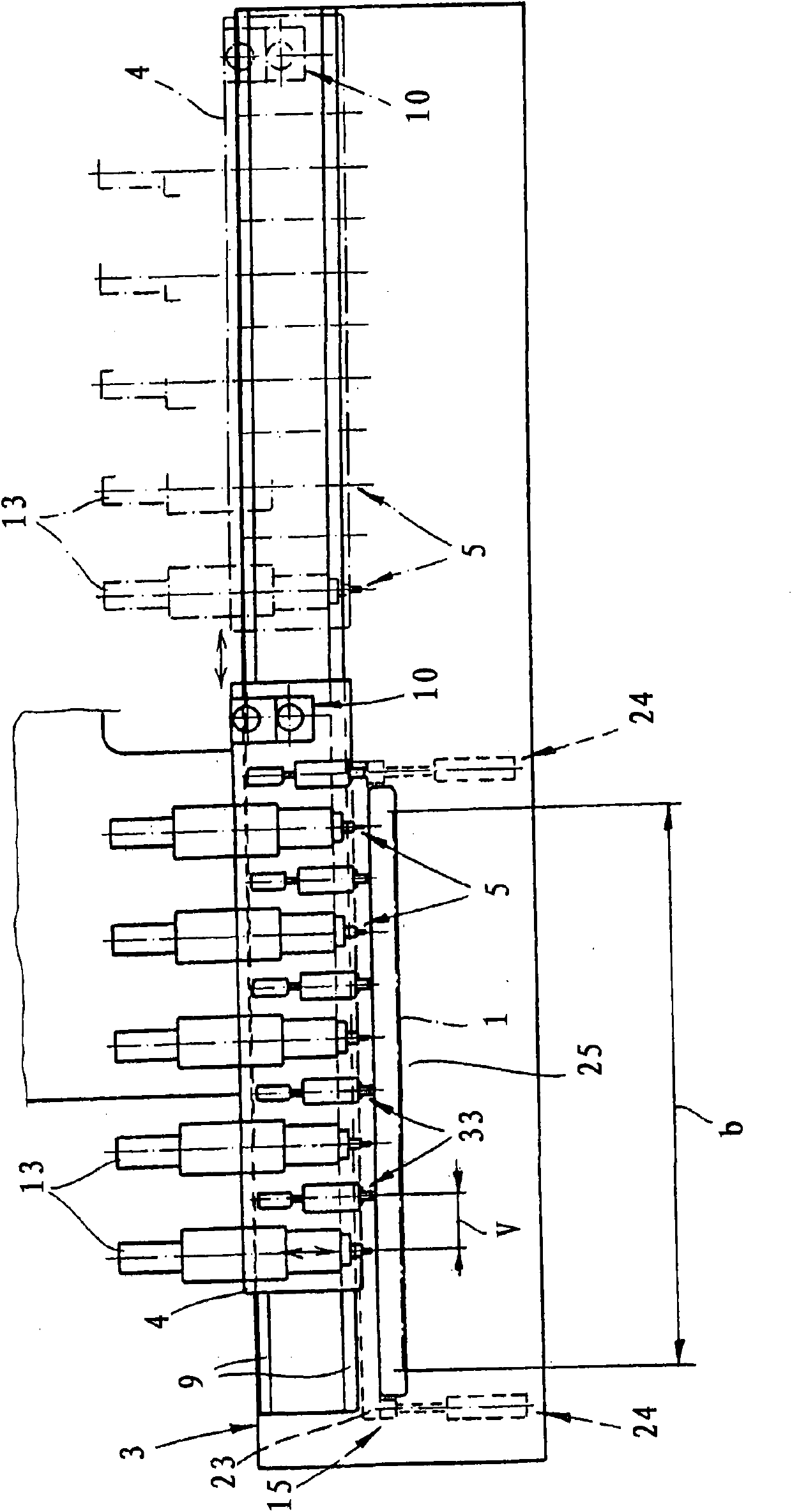

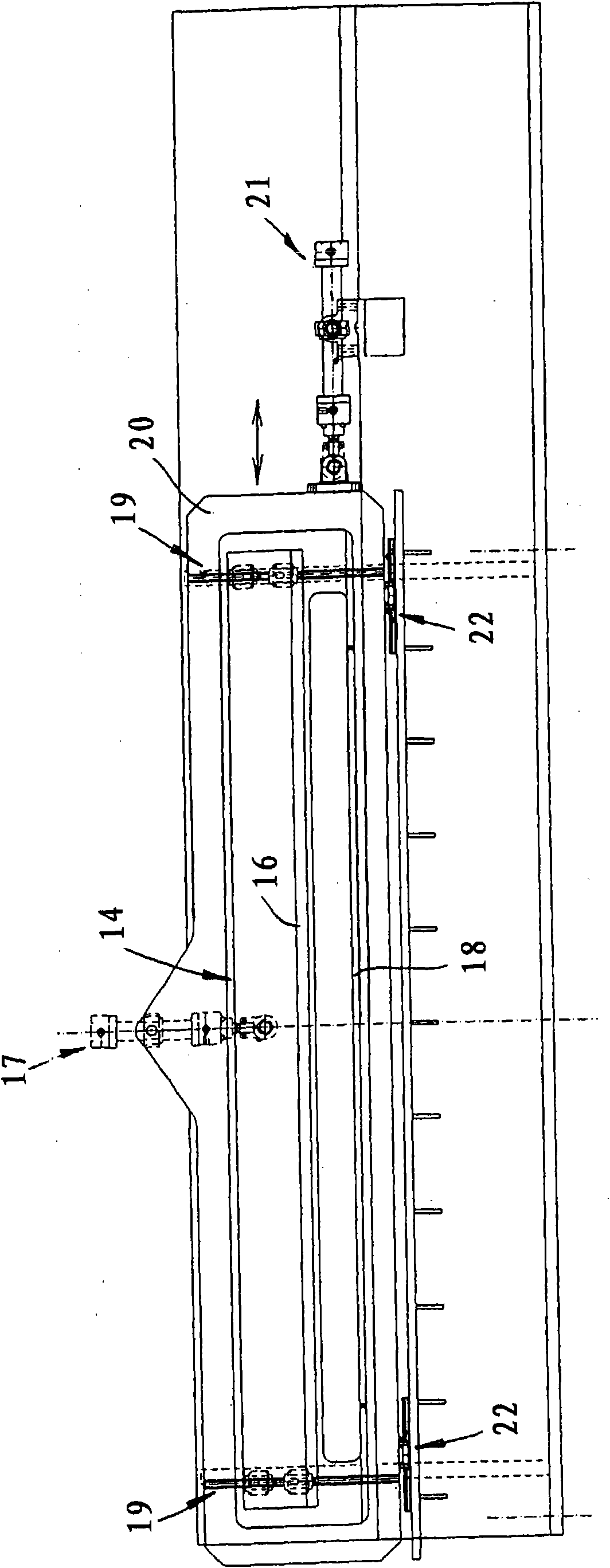

[0033] The figure shows a device for connecting a strip end 1 a of a first metal strip 1 and a strip start 2 a of a second metal strip 2 . Such a device is preferably integrated in an inlet area with a treatment device. In such strip processing plants (which are also referred to as strip processing lines), metal strips coiled into coils (coils) are unrolled in the entry area, then pass through different processing stations and are coiled up again in the exit area , or otherwise continue to be processed, such as being cut into metal blocks. The strip start 2a of a new strip is thus connected to the strip end 1a of the previous strip without having to constantly rethread the metal strip. Within the scope of the invention, this is achieved by welding, by positioning the strip end 1 a and the strip start 2 a one above the other with overlapping and welding to one another in the overlapping region at several welding points. During welding, the strip is in a rest position, ie the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com