Welding and forming device of concrete hollow square pile reinforcing cage

A hollow square pile, welding forming technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problem of not being able to weld square pile reinforcement cages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

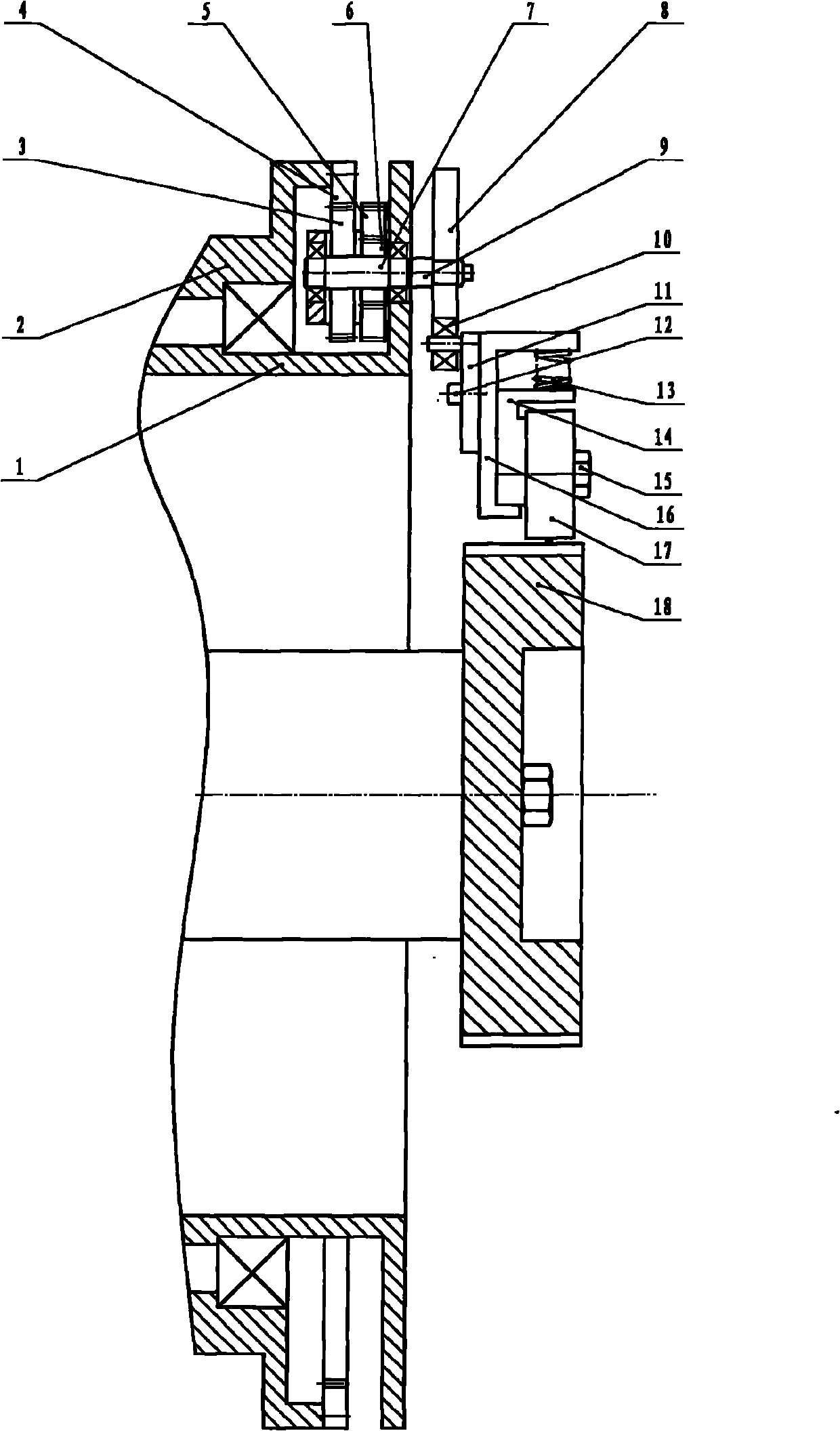

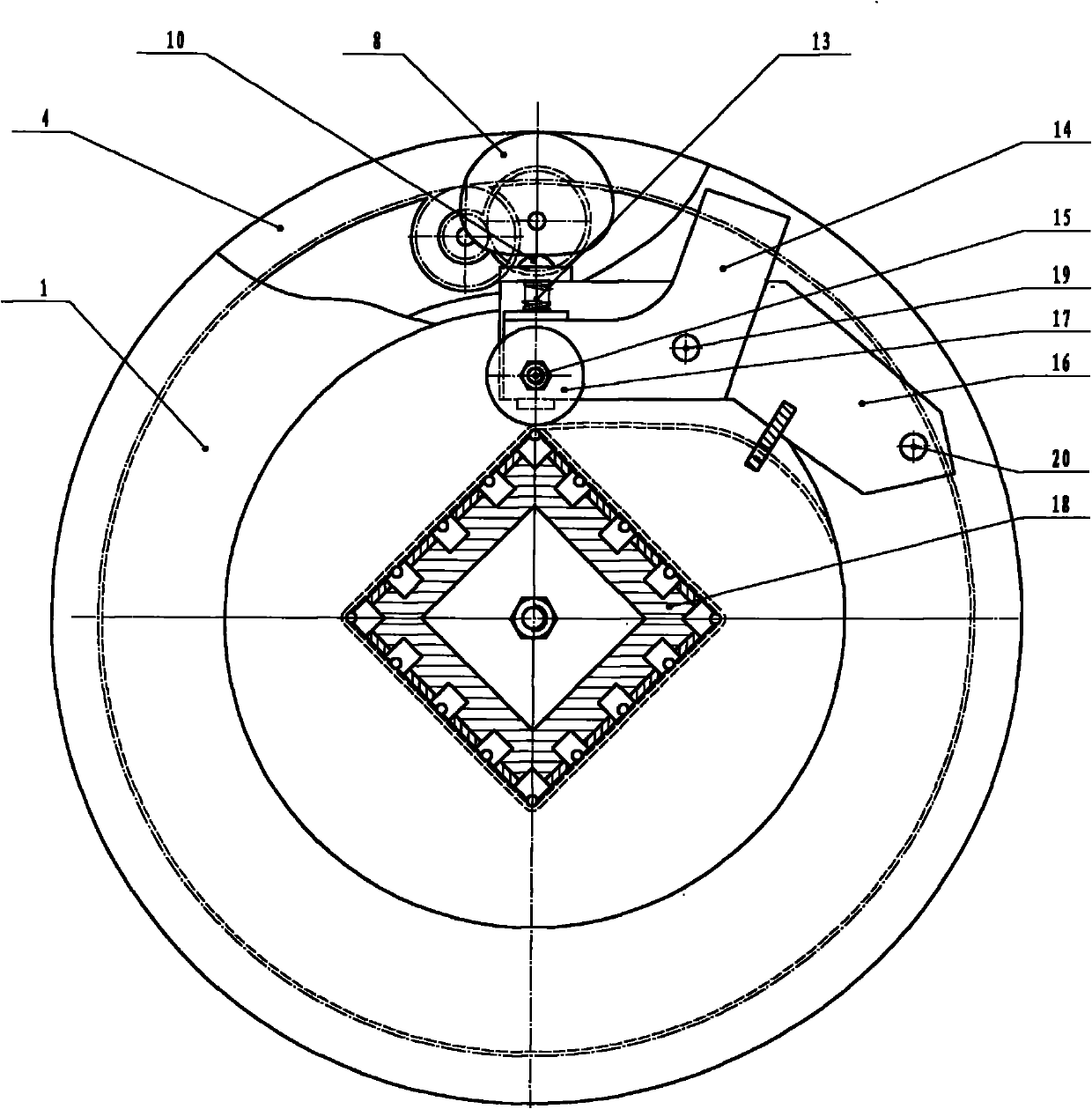

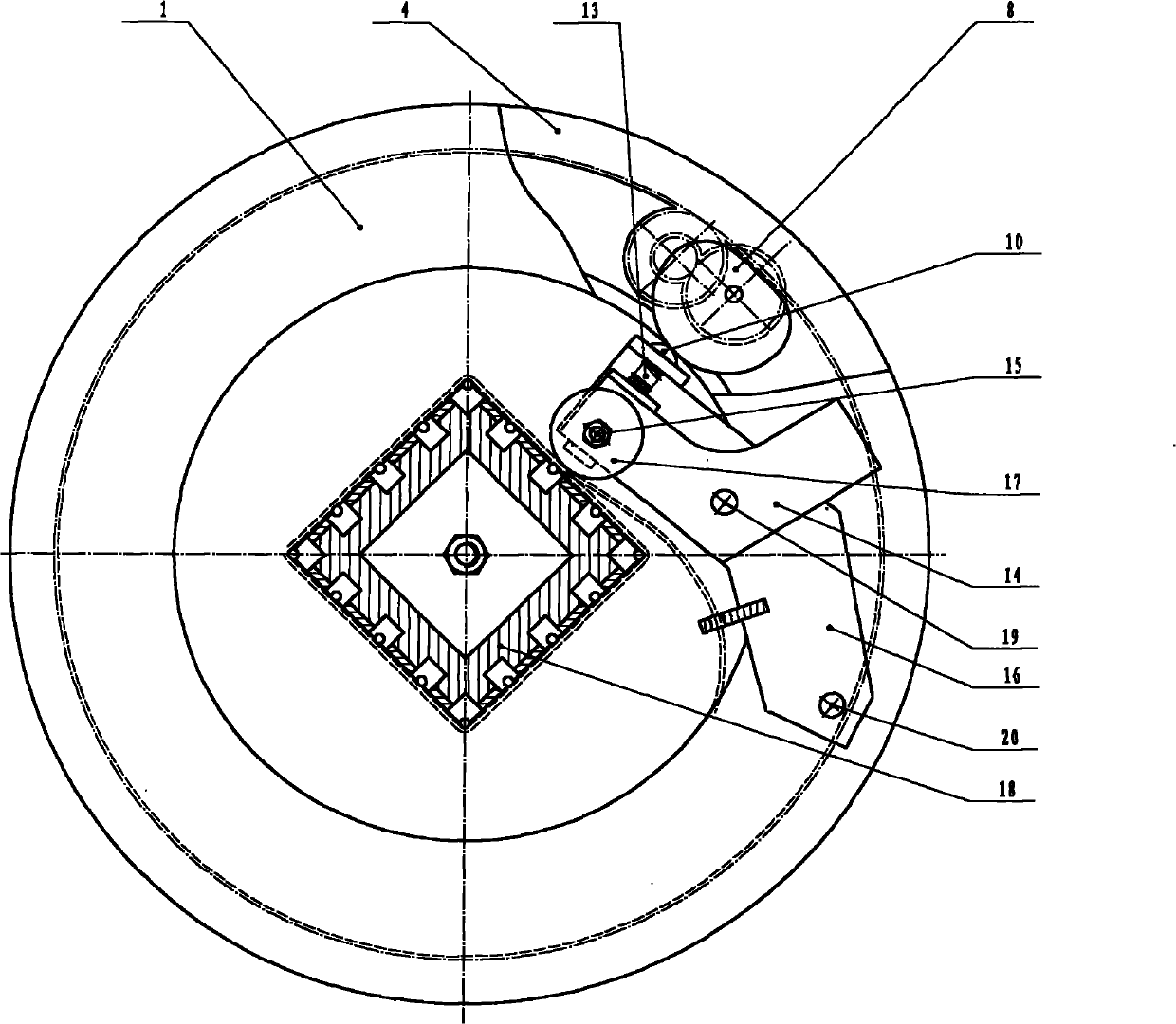

[0030] Technical solution of the present invention is made up of following three parts:

[0031] First of all, in the device composed of the turntable of the main engine, the internal gear transmission mechanism, the cam, the adjustable connecting rod with rolling bearings, the electrode welding arm, the electrode wheel assembly, and the electrode master, the movement track of the electrode wheel is exactly the same as the cross-sectional shape of the square master. Consistent, the idea is: the electrode master is installed on the base of the main machine and fixed, and the electrode arm is installed on the fixed shaft of the main machine turntable. In addition to doing circular motion with the main machine turntable, the electrode arm also swings up and down around the fixed shaft. The radial position of the arm is not fixed. The electrode master and the cam jointly define the radial position of the electrode arm from two different directions. There is only mechanical contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com