Stepped cylindrical component die for medium plate

A stepped and cylindrical technology, applied in the direction of perforating tools, forming tools, manufacturing tools, etc., can solve the problems of complex processing of stepped cylindrical parts, high cost of stepped cylindrical parts, complex mold structure, etc. Achieve the effect of eliminating uneven gap, uniform and stable material return force, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

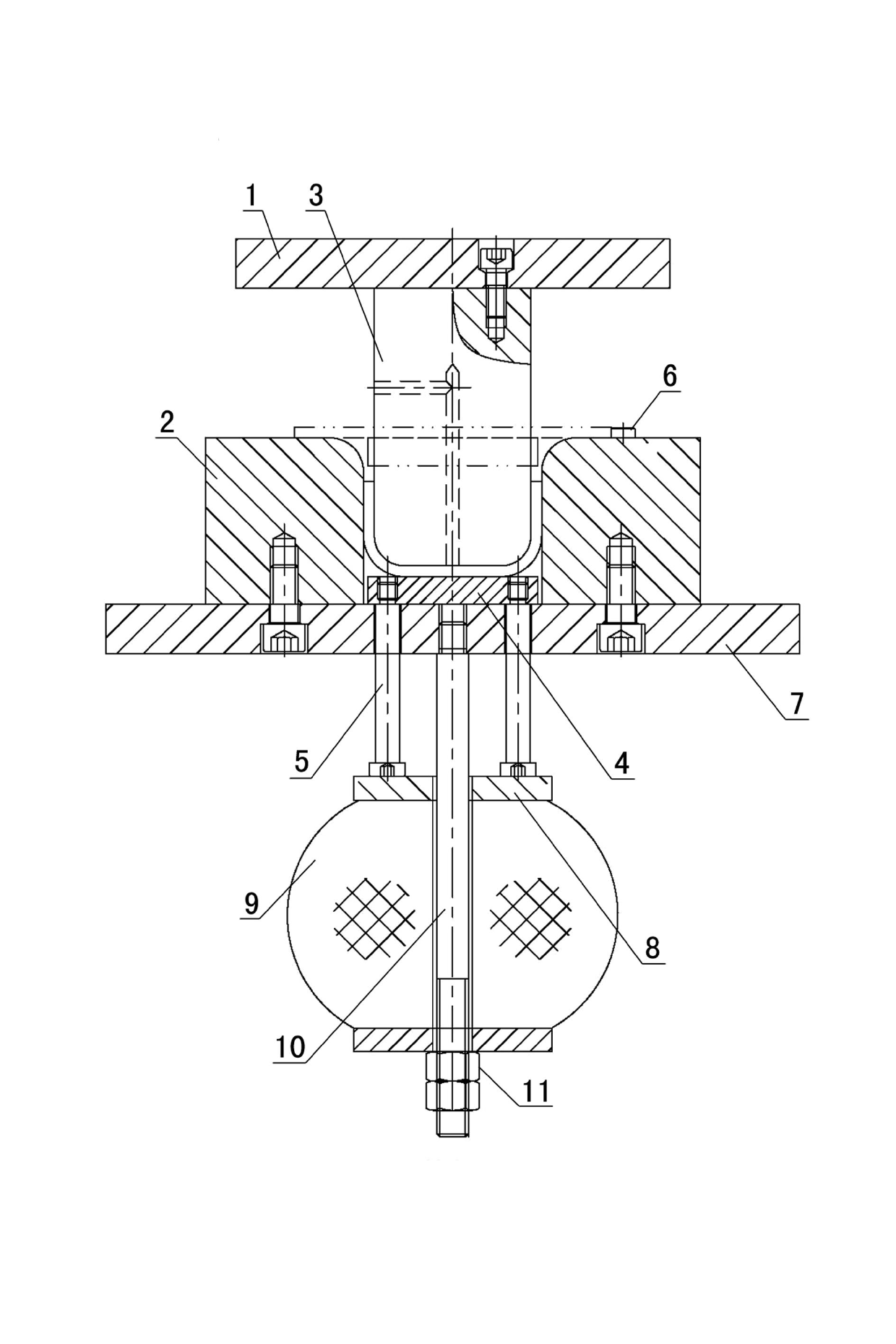

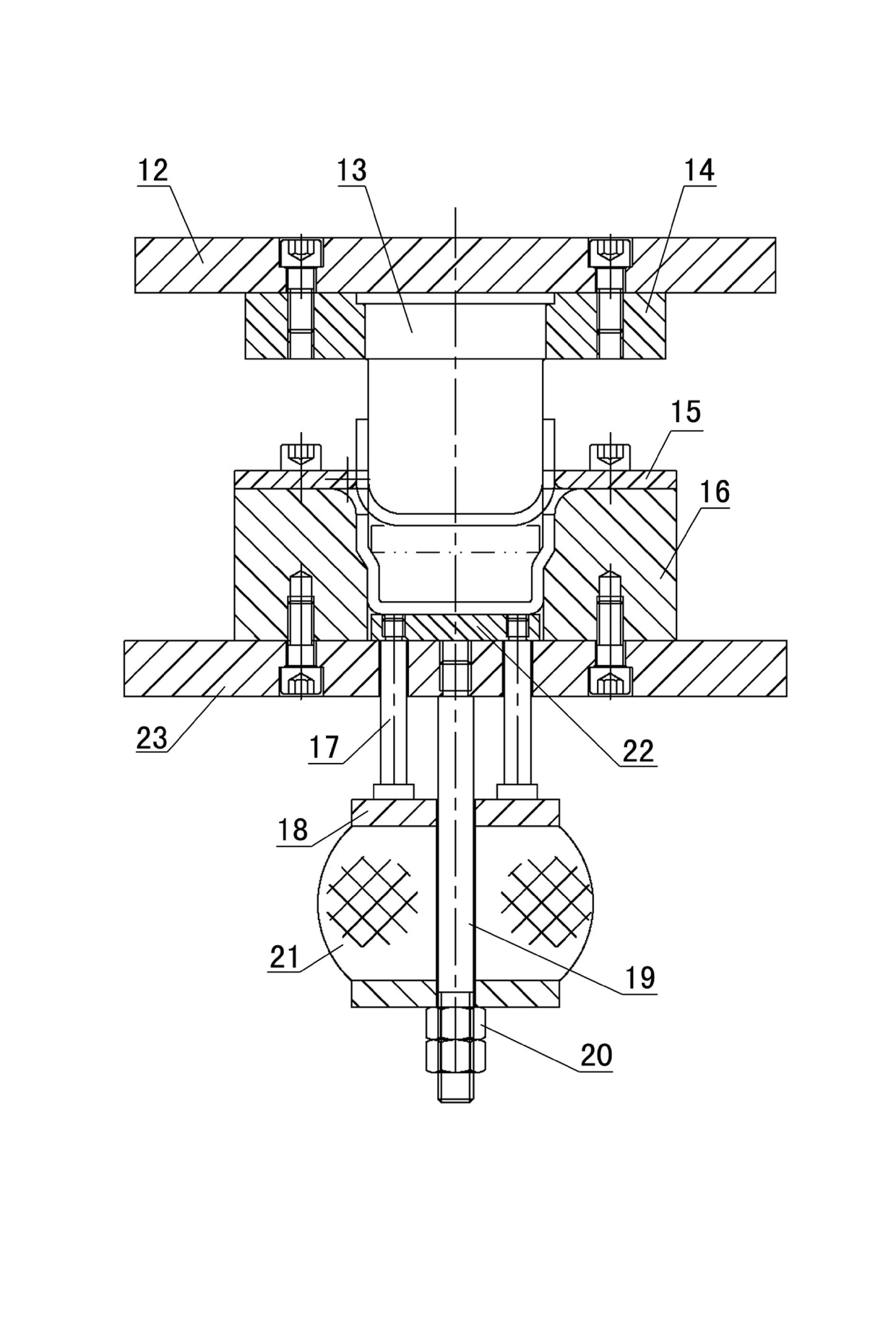

[0027] Examples see Figure 3-6 As shown, the mold for the stepped cylindrical part of the medium and thick plate is composed of three pairs of molds: the initial stretching die, the stretching shaping die and the punching die.

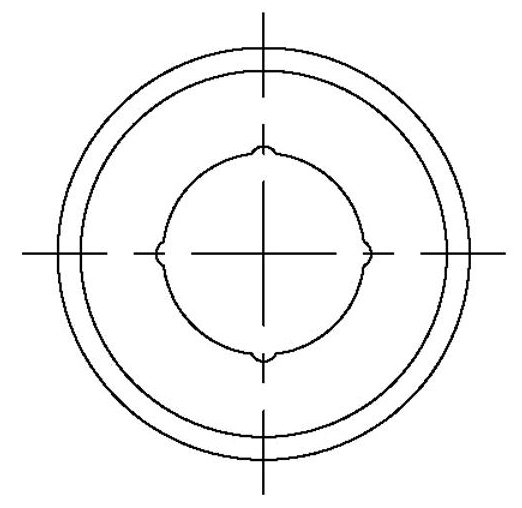

[0028] see image 3 , the primary stretching die is made up of stretching die upper die, stretching die lower die and stretching die stripping device, and described stretching die upper die comprises stretching die upper template 1 and is threadedly connected under the stretching die upper template The drawing die punch 3 on the surface, the drawing die lower die is connected on the drawing die die by the drawing die lower template 7, the drawing die die 2 that is threadedly connected on the drawing die lower template upper surface The positioning device is composed of, wherein the concave hole on the die die 2 of the drawing die is a straight hole.

[0029] The stretching die stripping device includes a stretching die stripping plate 4, a stretchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com