Composite type organic inhibitor for magnesia method desulfuration by-product recovery

A technology for organic inhibitors and desulfurization by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

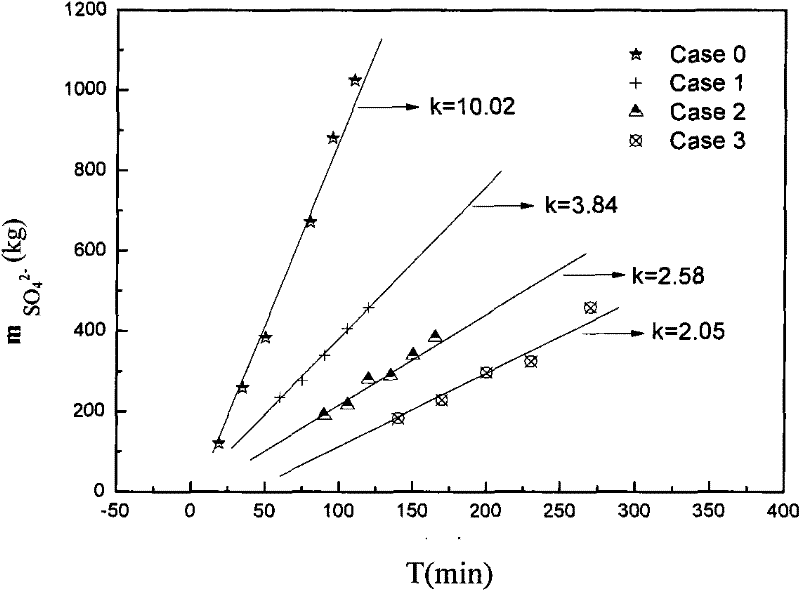

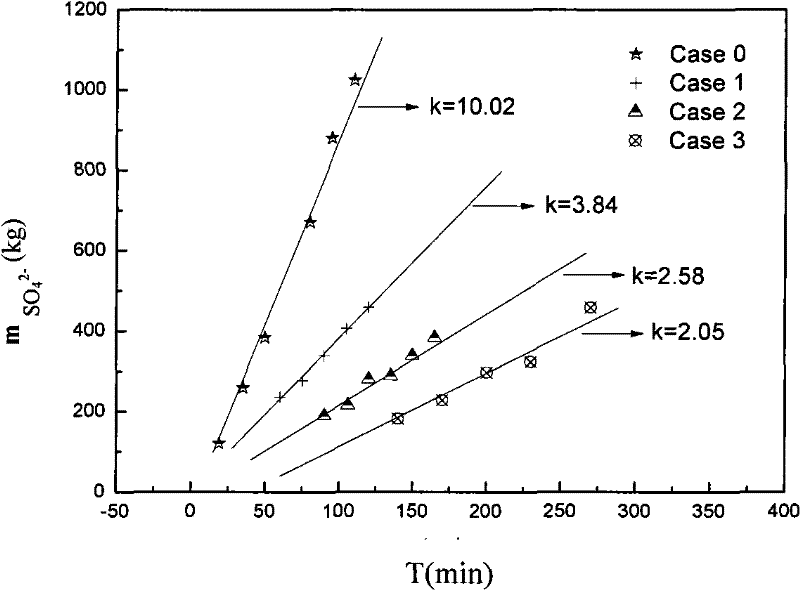

Image

Examples

Embodiment 1

[0019] Preparation and use of embodiment 1 inhibitor of the present invention

[0020] Weigh ascorbic acid (C 6 h 8 o 6 ) 1.88kg, ethanol (C 2 h 5 OH) 0.62L, phenol (C 6 h 5 OH) 1.0kg, dissolved in 0.5m at 40°C 3 In deionized water, adjust the pH value to about 7.0 with hydrochloric acid and ammonia water, stir and mix to make a compound organic inhibitor (in the compound organic inhibitor obtained in this embodiment, the molar ratio of ascorbic acid, phenol and ethanol is 1: 1 : 1).

[0021] During the desulfurization process, the magnesium hydroxide slurry reacts with the sulfur dioxide in the flue gas, and the obtained desulfurization slurry (the main components of the desulfurization slurry are magnesium sulfite and magnesium sulfate) enters the desulfurization holding tank, and the above-mentioned compound organic inhibitor 0.5m 3 , added to the desulfurization holding tank, the total volume of the reaction solution is 200m 3 , the concentration of ascorbic acid,...

Embodiment 2

[0022] The preparation and use of embodiment 2 inhibitors of the present invention

[0023] Weigh ascorbic acid (C 6 h 8 o 6 ) 4.70kg, ethanol (C 2 h 5 OH) 1.54L, phenol (C 6 h 5 OH) 2.51kg, dissolved in 0.5m at 40°C 3 In deionized water, adjust the pH value to about 6.5 with hydrochloric acid and ammonia water, stir and mix to make a compound organic inhibitor (in the compound organic inhibitor obtained in this embodiment, the molar ratio of ascorbic acid, phenol and ethanol is 1: 1 : 1).

[0024] During the desulfurization process, the magnesium hydroxide slurry reacts with the sulfur dioxide in the flue gas, and the obtained desulfurization slurry (the main components of the desulfurization slurry are magnesium sulfite and magnesium sulfate) enters the desulfurization holding tank, and the above-mentioned compound organic inhibitor 0.5m 3 , added to the desulfurization holding tank, the total volume of the reaction solution is 200m 3 , the concentration of ascorbic...

Embodiment 3

[0025] The preparation and use of embodiment 3 inhibitors of the present invention

[0026] Weigh ascorbic acid (C 6 h 8 o 6 ) 23.5kg, ethanol (C 2 h 5 OH) 3.75L, phenol (C 6 h 5 OH)6.25kg, dissolved in 2.5m at 40℃ 3 In deionized water, adjust the pH value to about 6.5 with hydrochloric acid and ammonia water, stir and mix to make a compound organic inhibitor (in the compound organic inhibitor obtained in this embodiment, the molar ratio of ascorbic acid, phenol and ethanol is 2: 1 : 1).

[0027] During the desulfurization process, the magnesium hydroxide slurry reacts with the sulfur dioxide in the flue gas, and the resulting desulfurization slurry (the main components of the desulfurization slurry are magnesium sulfite and magnesium sulfate) enters the desulfurization holding tank, and measures 2.0m of the above-mentioned compound organic inhibitor 3 , added to the desulfurization holding tank, the total volume of the reaction solution is 200m 3 , the concentrations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com