Stator structure of submersible motor and manufacturing method thereof

A technology of stator structure and submersible motor, which is applied in the manufacture of motor generators, stator/rotor body, magnetic circuit shape/style/structure, etc., can solve the problems of complex motor structure, high manufacturing cost and large mechanical loss, etc. Avoid the effect of low tank fill rate, low cost and effective welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

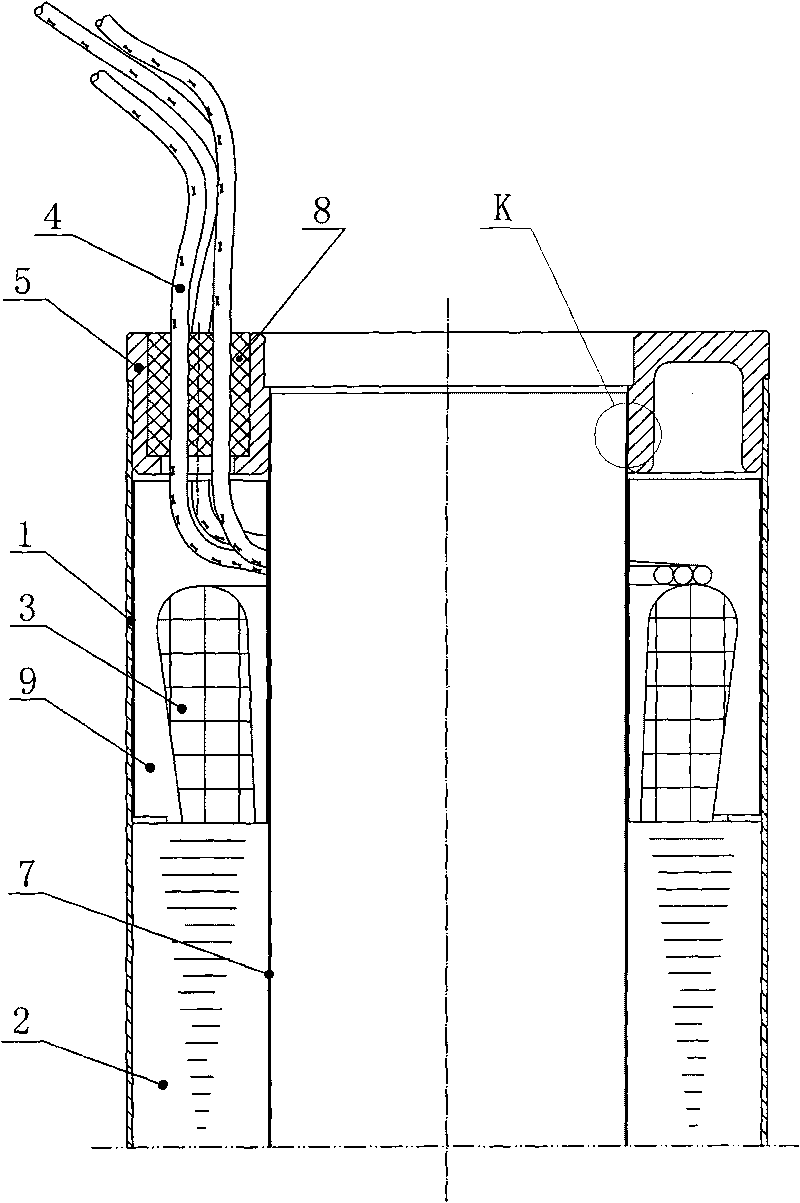

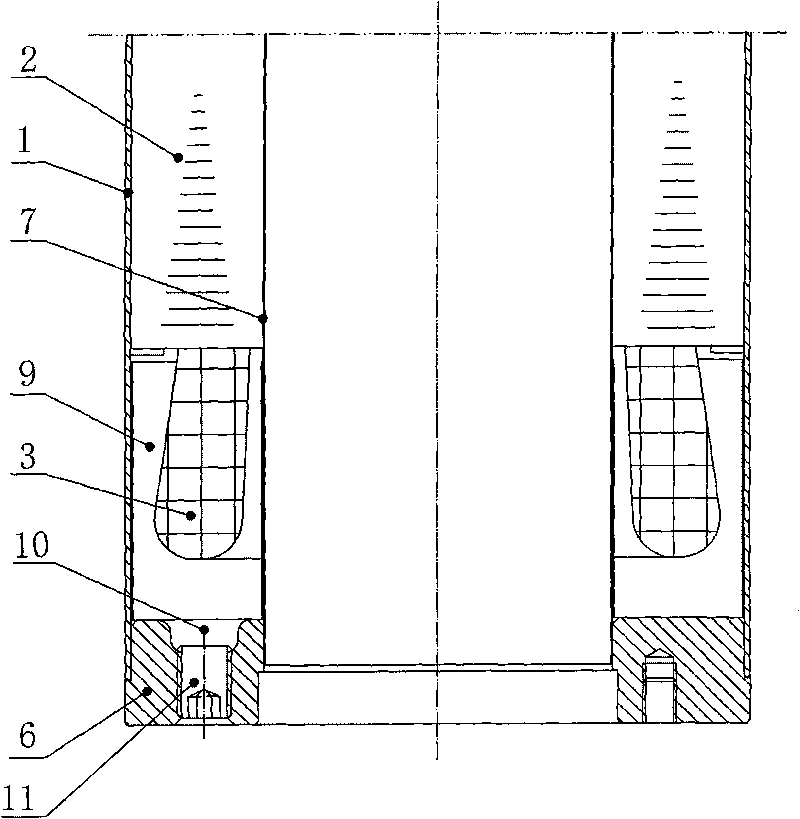

[0022] The stator structure of the submersible motor of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1~3 As shown, the embodiment of the stator structure of the submersible motor of the present invention is: including the stator shell 1, the iron core 2, the stator winding 3 and the winding lead wire 4, and the upper and lower ends of the stator shell 1 are welded with upper flange end rings respectively 5 and the lower flange end ring 6, there is also an airtight stainless steel shielding sleeve 7 with a wall thickness of 0.08-0.18 mm sealed and welded on the inner wall of the iron core 2 and extending to the upper flange end ring 5 and the lower flange On the flange end ring 6, on the upper flange end ring 5, there is also a lead wire sealing device 8 that seals and wraps the periphery of the winding lead wire 4, between the stator shell 1 and the shielding sleeve 7 and the upper flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com