Battery manufacturing method and battery

A production method and battery technology, which is applied to secondary batteries, battery components, circuits, etc., can solve the problems of reduced effective height of electrodes and inability to manufacture batteries, and achieve the effects of increased volume, reduced assembly ratio, and increased electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

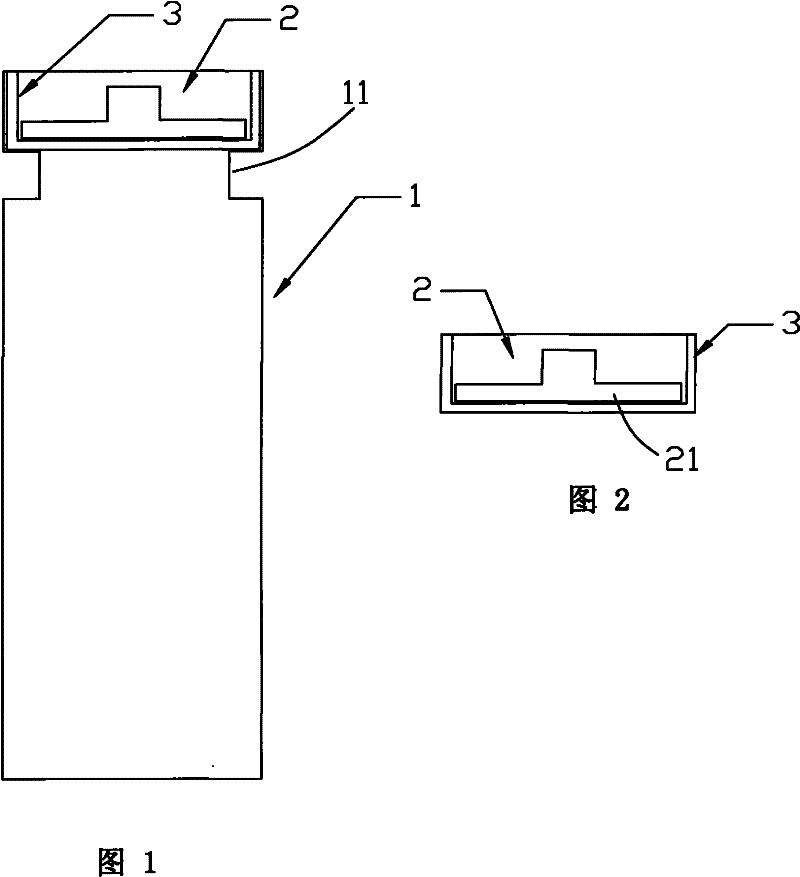

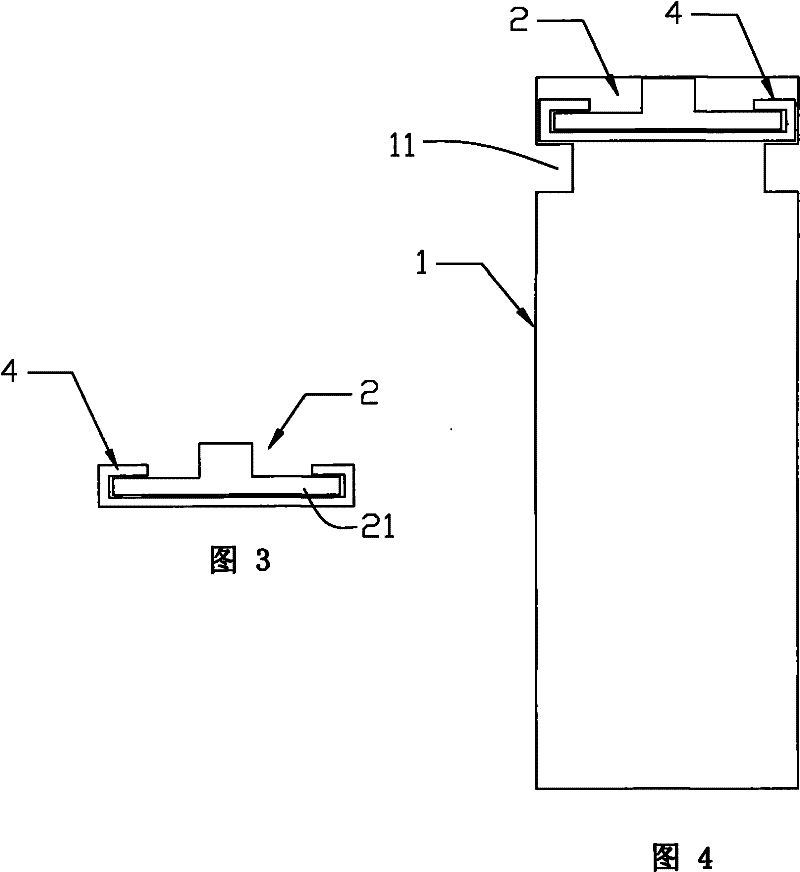

[0020] The battery manufacturing method of the present invention is to put the cap into the heat-shrinkable sealing ring before putting the cap of the battery into the casing for sealing, heat the heat-shrinkable sealing ring so that the sealing ring is heated and shrinks to cover the cap, and then seal the cap with the sealing ring. Put the cap of the ring into the battery case, and perform piping sealing, so that the battery case encloses the sealing ring. How to implement the battery manufacturing method of the present invention will be described in detail below in conjunction with the embodiments.

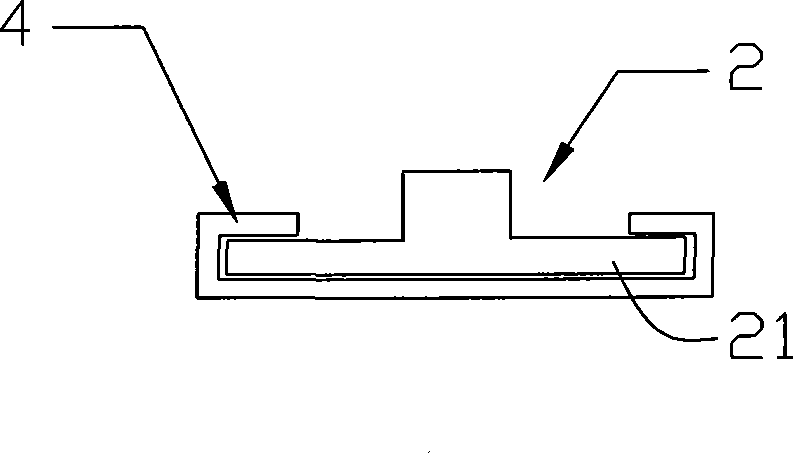

[0021] One embodiment of the battery production method of the present invention is a steel case nickel-hydrogen battery production method, see image 3 , Figure 4 Before putting the cap 2 of the battery into the battery case 1, put the cap 2 into the heat-shrinkable sealing ring 4, the heat-shrinkable sealing ring 4 is made of polyethylene (PE plastic) or polypropylene (PP pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com