Industrial process dynamic optimization system and method based on nonlinear conjugate gradient method

A conjugate gradient method, an industrial process technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve difficult problems such as accuracy and high efficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

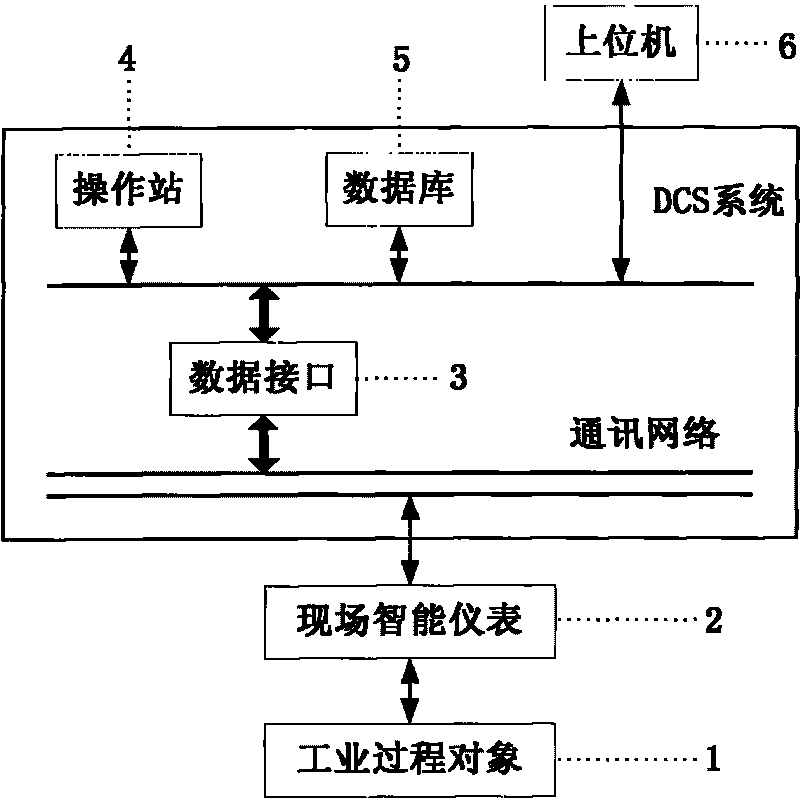

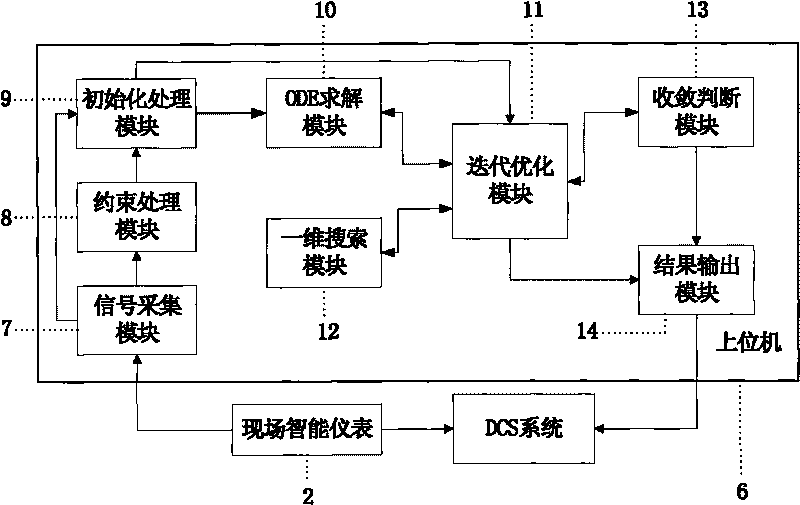

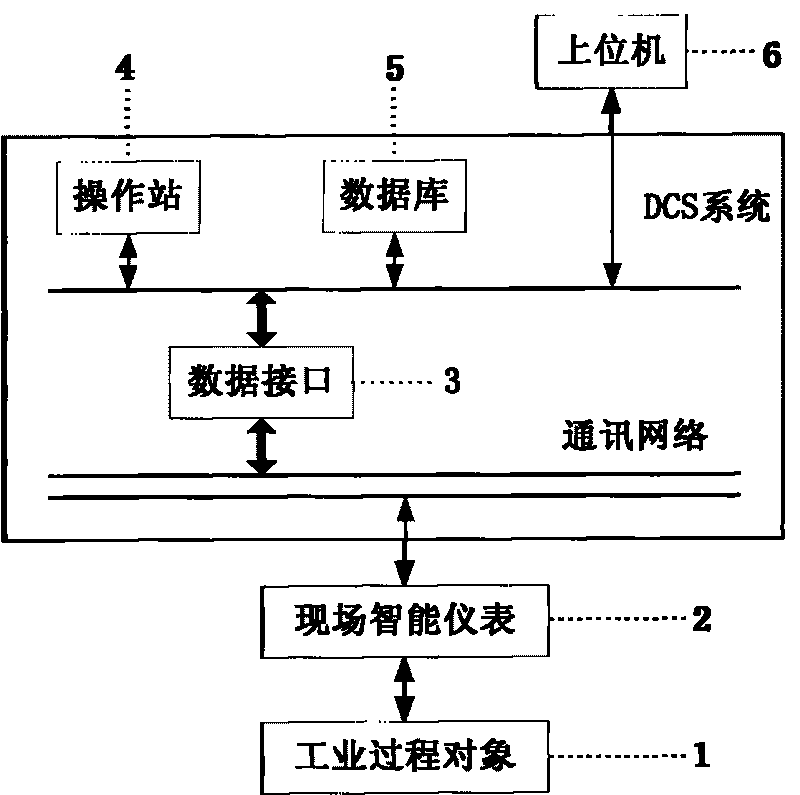

[0113] Reference figure 1 , figure 2 , An industrial process dynamic optimization system based on nonlinear conjugate gradient method, including field intelligent instrument 2, DCS system and host computer 6 connected with industrial process object 1. Said DCS system consists of data interface 3 and operating station 4. The database 5 is composed; the field intelligent instrument 2 is connected to the communication network, the communication network is connected to the data interface 3, the data interface 3 is connected to the field bus, and the field bus is connected to the operating station 4, the database 5 and the host computer 6. , The upper computer includes:

[0114] The constraint processing module 8 is used to process the boundary constraints of the control variables in the optimization process, using the following conversion equation:

[0115] u(t)=0.5(u max -u min )×{sin[w(t)]+1}+u min (1)

[0116] Will have boundary constraints u min ≤u(t)≤u max The control var...

Embodiment 2

[0163] Reference figure 1 with figure 2 , An industrial process dynamic optimization based on the nonlinear conjugate gradient method, the dynamic optimization method is implemented according to the following steps:

[0164] 1) Specify the state variables and control variables for dynamic optimization in the DCS system, and set the upper and lower boundaries of the control variables according to the conditions of the actual production environment and operating restrictions. max , U min And DCS sampling period, and the historical data of the corresponding variables in the DCS database 5 to control the upper and lower boundary values u max , U min Sent to the host computer 6.

[0165] 2) In the constraint processing module 8 of the host computer, through trigonometric function substitution, the unconstrained conversion of the boundary-constrained control variable u(t) is performed, and it is replaced with the function expression of the intermediate variable w(t), namely :

[016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com