Device for testing torsion and vibration of rotor of revolution vane minitype compressor and test method

A compressor rotor and torsional vibration technology, which is applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve problems such as low signal-to-noise ratio, large installation space, large error, etc., and improve the accuracy of measurement , The effect of improving voltage sensitivity and eliminating nonlinear errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

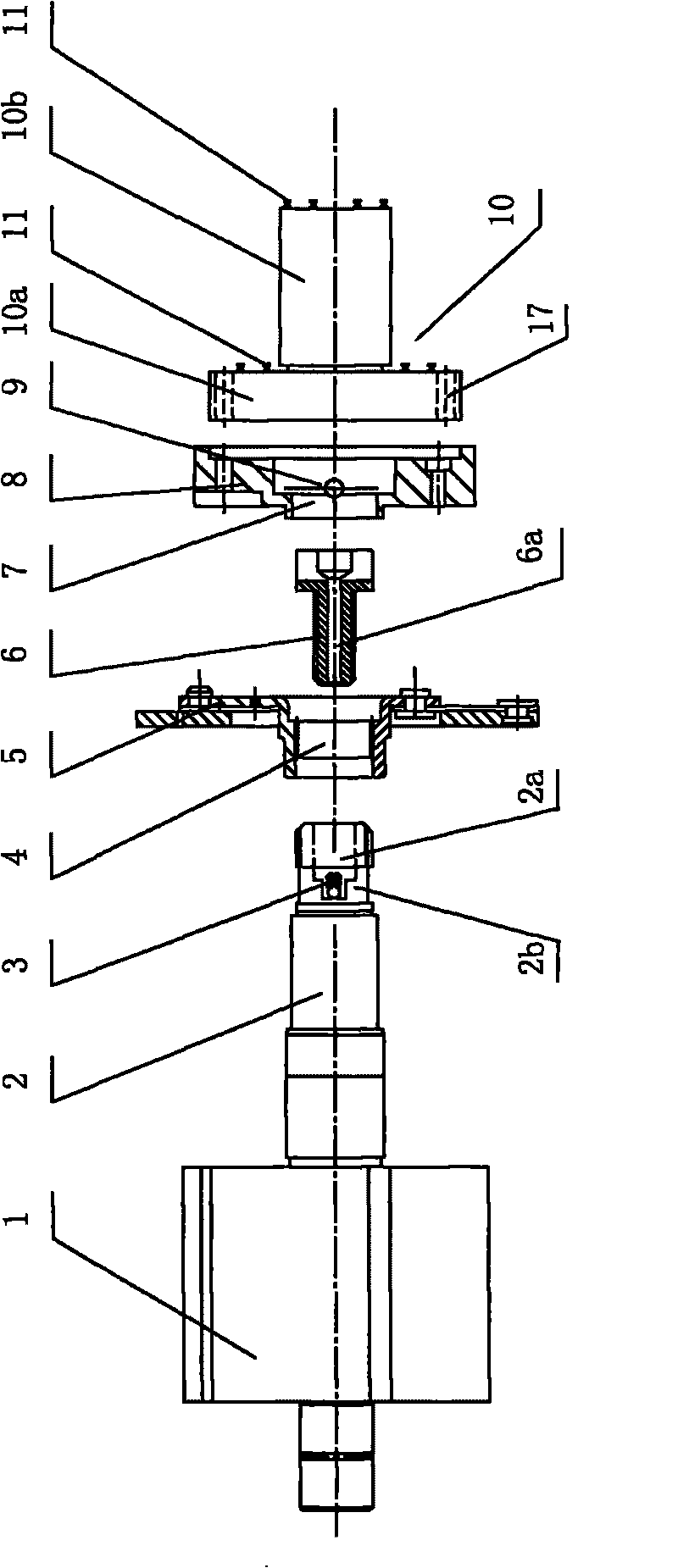

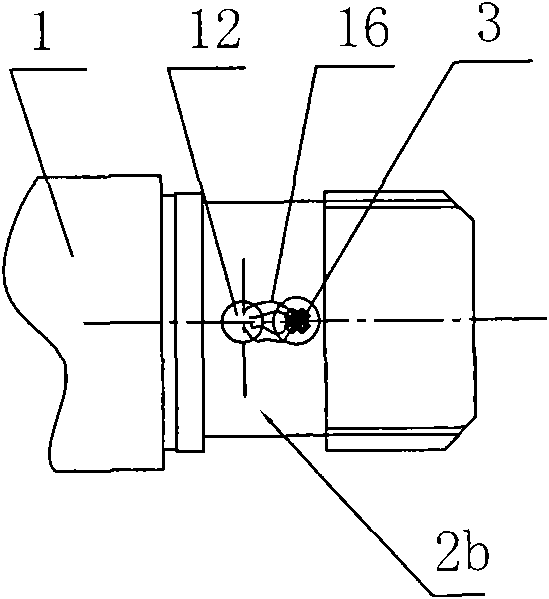

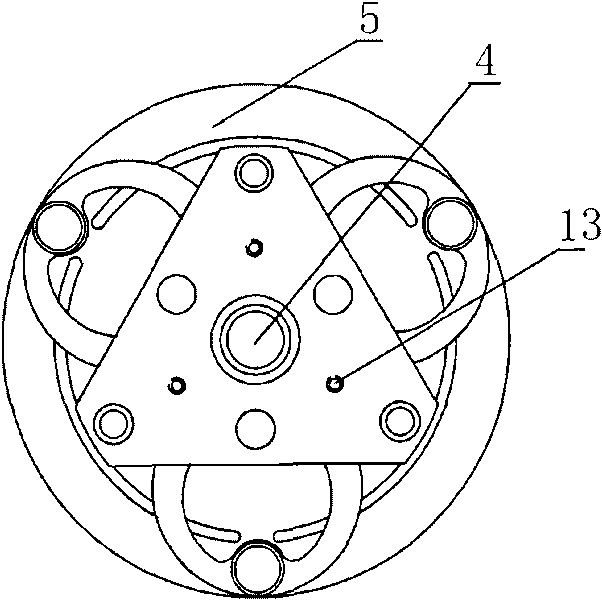

[0049] see Figure 1 to Figure 4 with Figure 7 , a rotary vane type small compressor rotor torsional vibration test device, a rotating part 10a of a brush-type conductive ring 10 is connected to a mounting plate 8 by screws, and two screws are connected from the rotating part of the brush-type conductive ring 10 respectively The two mounting holes 17 provided on 10 a pass through and are fastened to the two threaded holes 14 on the mounting plate 8 , so as to fix the brush-type conductive ring 10 on the mounting plate 8 . The mounting plate 8 is provided with a central via hole 7 in the axial direction, and the central via hole 7 is radially provided with a through hole 9 that runs through the mounting plate 8. The eccentric position of the mounting plate 8 is provided with three via holes 15, and three screws pass through the mounting plate 8 respectively. The three through holes 15 are firmly connected with the three mounting threaded holes 13 provided on the compressor ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com