Method for separating light dydrocarbon aromatization dry gas

A technology of aromatization and dry gas, which is applied in the direction of hydrocarbon purification/separation, absorption purification/separation, chemical instruments and methods, etc., and can solve the problems of no production, no production of high-purity benzene, no formal production, etc. Achieve the effects of increasing output value, solving rational utilization problems, and eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: Taking C4 and C5 aromatization dry gas separation as an example

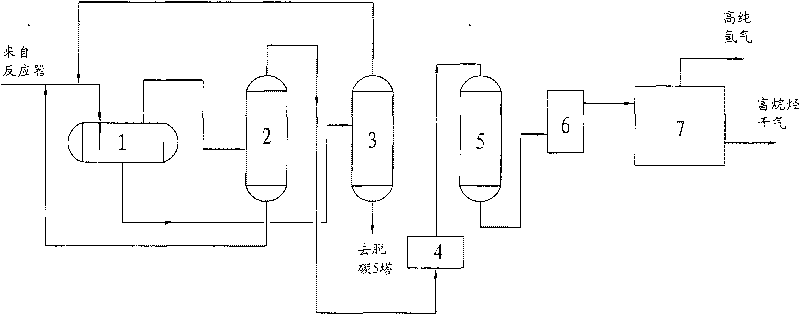

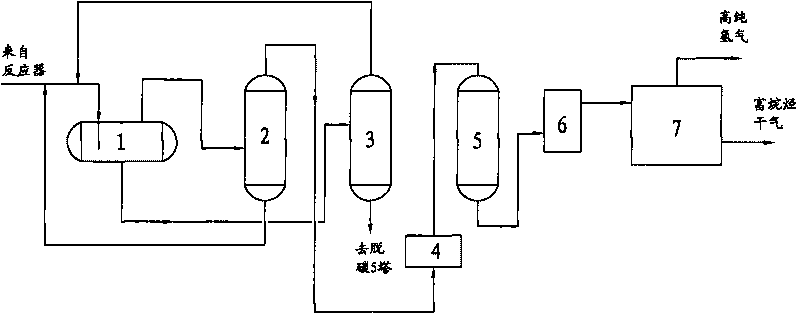

[0031] Such as figure 1 As shown, a method for the separation of light hydrocarbon aromatization dry gas comprises a reaction liquid separation tank 1, an absorption tower 2, and an analysis tower 3, and the reaction gas in the reaction liquid separation tank 1 enters the bottom of the absorption tower 2 for further absorption and separation of condensable C 5 For the above hydrocarbons, the absorbent in the absorption tower 2 is C from the deheptanizer 8 -C 10 distillate and C from the extractive cut column 8 -C 10 fraction. The bottom flow of the absorption tower 2 returns to the reaction liquid separation tank 1, and the gas at the top of the tower enters the hydrogen production device 7 after passing through the first-level gas-liquid separation tank 4, the hydrogenation reactor 5, and the second-level gas-liquid separation tank 6, and the separated high-purity hydrogen To the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com