Low slump loss modified naphthalene series water-reducing agent and preparation method thereof

A naphthalene-based water reducer and slump loss technology, which is applied in the field of concrete water reducer and its preparation, can solve the problems of large slump loss over time and difficult construction, so as to ensure the water reducing effect, good effect, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

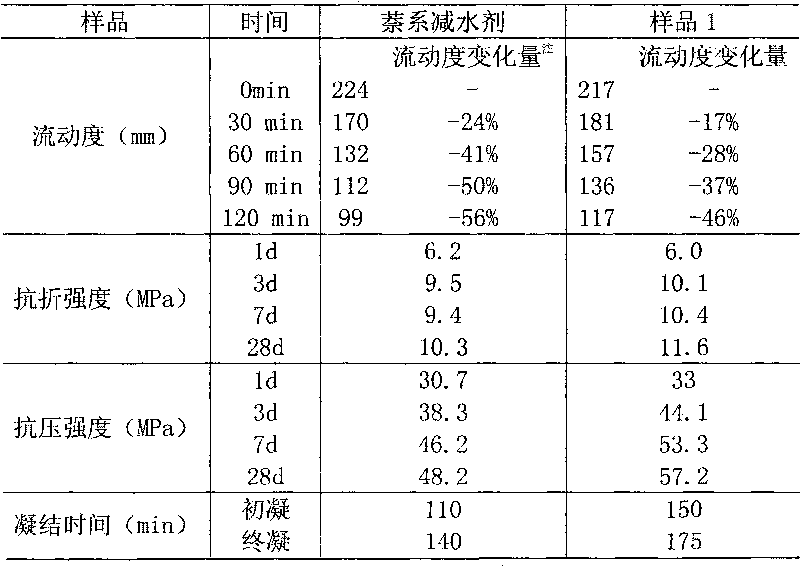

[0028] A modified naphthalene-based water reducer with low slump loss, which is composed of 19 parts by weight of naphthalene-based water reducer and 1 part by weight of oxidized-etherified starch, represented by sample 1.

[0029] The determination method of cement slurry setting time is in accordance with GB / T 1346-2001. The method for measuring the fluidity of cement paste is in accordance with GB8077-2000. When measuring the mortar strength, the mortar-sand ratio is 1:2, and the water-cement ratio is w / c=0.325.

[0030] The modified naphthalene-based water reducer (sample 1) of this embodiment is used in concrete, and the dosage of the modified naphthalene-based water-reducer is 0.6% of the cement weight and remains unchanged; For comparison, its performance indicators are shown in Table 1:

[0031] Table 1 Comparison between sample 1 and naphthalene-based water reducer

[0032]

[0033] Note: The formula for calculating the change in fluidity is: (fluidity over time...

Embodiment 2

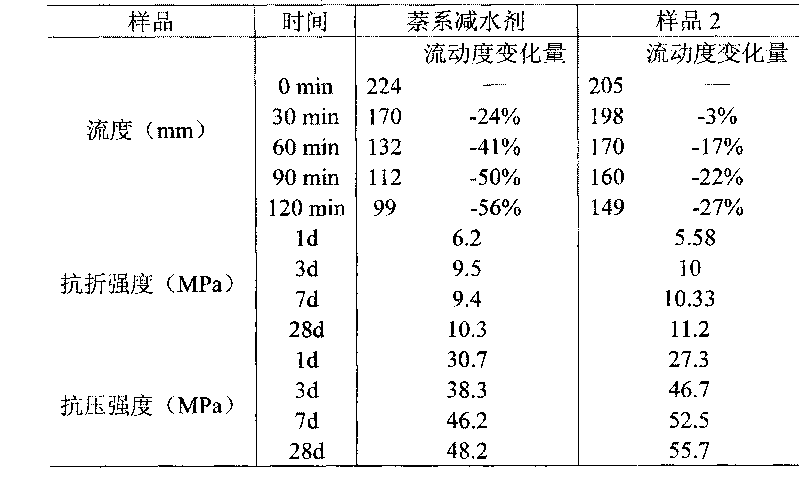

[0037] A modified naphthalene-based water reducer with low slump loss is composed of 23 parts by weight of naphthalene-based water reducer and 2 parts by weight of oxidized-etherified starch, represented by sample 2.

[0038] The modified naphthalene-based water reducer (sample 2) of this example is used in concrete, and the dosage of the modified naphthalene-based water-reducer is 0.6% of the cement weight and remains unchanged; For comparison, its performance indicators are shown in Table 2:

[0039] Table 2 Comparison between sample 2 and naphthalene-based water reducer

[0040]

[0041] It can be seen from Table 2 that increasing the amount of modified starch can further improve the fluidity of cement, and the strength after 3 days is also increasing.

Embodiment 3

[0043] A modified naphthalene-based water reducer with low slump loss, which is composed of 87 parts by weight of naphthalene-based water reducer and 13 parts by weight of oxidized-etherified starch, represented by sample 3.

[0044] The modified naphthalene-based water reducer (sample 3) of this embodiment is used in concrete, and the dosage of the modified naphthalene-based water-reducer is 0.6% of the cement weight and remains unchanged; For comparison, its performance indicators are shown in Table 3:

[0045] Table 3 Comparison between sample 3 and naphthalene-based water reducer

[0046]

[0047] It can be seen from Table 3 that when the amount of modified starch superplasticizer reaches a certain level, the change of cement fluidity with time increases first and then decreases, which is more conducive to the long-term mixing and transportation of concrete, and after 2 hours, The loss of fluidity is small. Moreover, the strength of cement added with the modified naph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com