Composite forging inner/outer same set process of small-medium size British system conical bearing sleeved column

A tapered bearing, the same set of technology inside and outside, used in metal rolling, metal processing equipment, metal extrusion dies, etc., can solve problems such as inconvenient balanced production, increased quality risks of foreign trade export products, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

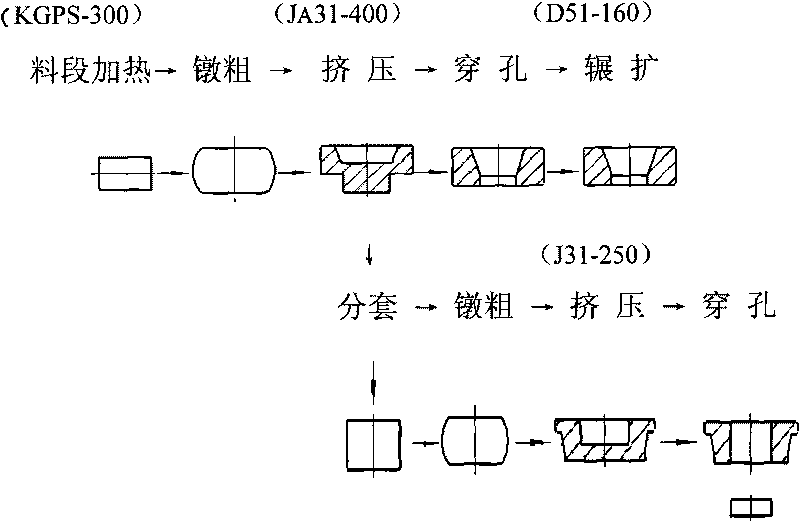

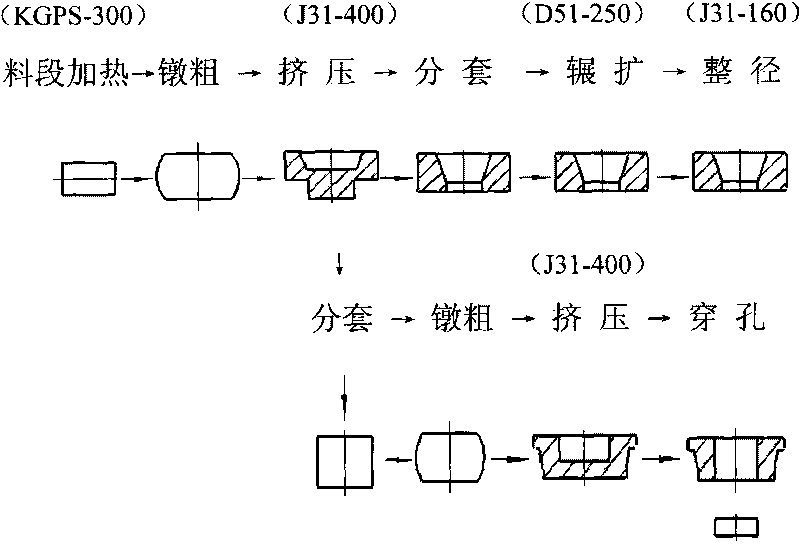

Method used

Image

Examples

Embodiment Construction

[0032] Heating process: use medium frequency induction electric heating and auxiliary infrared heating temperature control to realize continuous heating and monitoring of bars.

[0033] The principle of medium-frequency induction electric heating is to use the "skin" effect of metals to pass alternating current into the inductor to generate alternating magnetic fields. Under its action, alternating eddy currents are generated inside the metal blank. Due to the eddy current heating and magnetization If the heat is generated, the metal blank is directly heated, thereby avoiding the problem of uneven heating temperature of the metal blank. It has fast heating speed, less oxidation burning loss (burning loss rate 5‰), good heating quality and very stable, easy to realize automation.

[0034] The principle of infrared heating temperature control is: set a temperature sensor at the discharge port, receive the temperature signal, convert the temperature signal into an electrical sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com