Method for floating bauxite

A bauxite and flotation process technology, applied in flotation, solid separation and other directions, can solve the problems of shortening the flotation process flow, low efficiency of the feeding slurry pump, etc., to solve the problem of foam transmission, improve the beneficiation index, The effect of reducing the flotation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

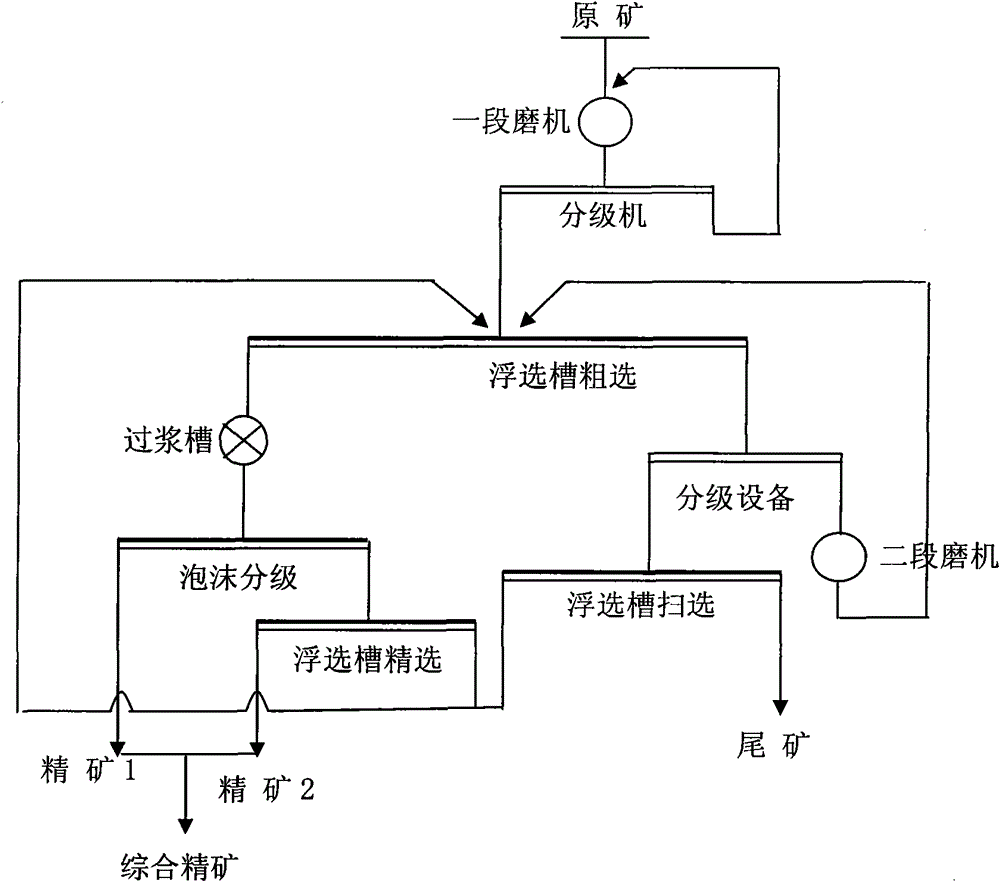

[0018] The low-grade bauxite with A / Sfigure 1 , the specific process of its desiliconization is as follows:

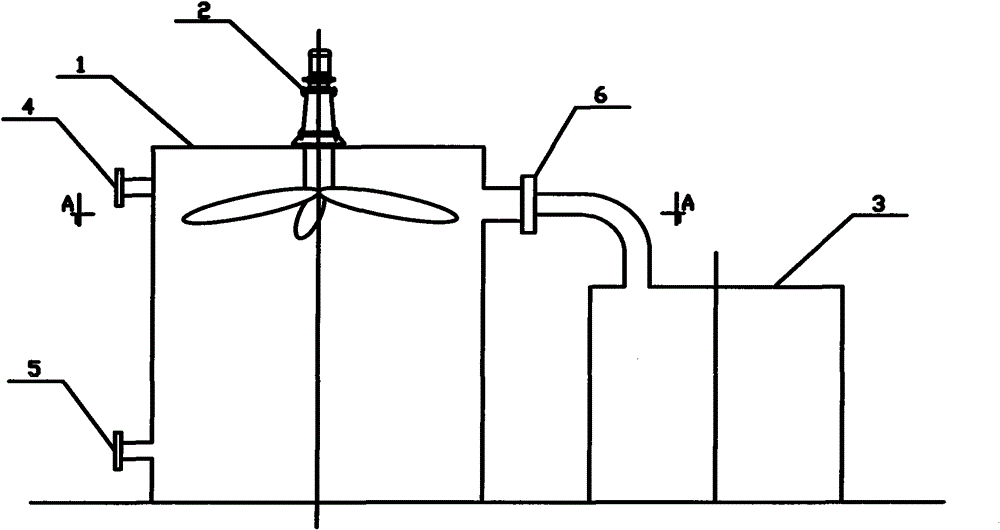

[0019] Low-grade bauxite in Henan with a processing capacity of 2t / h in The ore is ground in a grid-type ball mill, and an appropriate amount of sodium carbonate dispersant is added to the mill. The grinding fineness of the obtained grinding product is -0.074mm, accounting for 78.6%. The grinding product is the overflow of the classifier into the raw ore pulp for stirring After the barrel is treated with flotation reagents including 80g / t adjuster and 400g / t collector, it is pumped into the non-drive flotation tank through the slurry pump for rough selection, and the rough-selected foam product enters the slurry tank. Under the action of the spray water, the low-grade ore pulp after the foam is partially digested and the high-grade mineralized foam that is difficult to digest after enrichment are obtained. The enriched mineralized foam floats on the pulp and passes th...

Embodiment 2

[0027] The low-grade bauxite in Henan Province with an A / S of about 4.2 was used as the test sample. The main chemical composition and phase composition of the raw ore are shown in Table 4 and Table 5, respectively. The principle process flow chart is attached figure 1 , the specific process of its desiliconization is as follows:

[0028] Low-grade bauxite in Henan with a processing capacity of 80t / h Grinding in a rod mill, adding an appropriate amount of sodium carbonate dispersant into the mill, the grinding fineness of the obtained grinding product is -0.074mm, accounting for 67.5%, and the grinding product is the overflow of the classifier into the raw ore pulp for stirring After the barrel is treated with flotation agent including 80g / t adjuster and 450g / t collector, it is pumped into the non-drive flotation tank through the slurry pump for rough selection, and the rough-selected foam product enters the slurry tank. Under the action of the spray water, the low-grade or...

Embodiment 3

[0036] Taking low-grade bauxite with an A / S of about 5.7 in Shanxi Jinnan as the test sample, the main chemical composition and phase composition of the raw ore are shown in Table 7 and Table 8, respectively. The principle process flow chart is attached figure 1 , the specific process of its desiliconization is as follows:

[0037] Low-grade bauxite in Henan with a processing capacity of 2.1t / h The ore is ground in a grid-type ball mill, and an appropriate amount of sodium carbonate dispersant is added to the mill. The grinding fineness of the obtained grinding product is -0.074mm, accounting for 56.8%. The grinding product is the overflow of the classifier into the raw ore pulp for stirring After the barrel is treated with flotation reagents including 80g / t adjuster and 300g / t collector, it is pumped into the non-drive flotation tank through the slurry pump for rough selection, and the rough-selected foam product enters the slurry tank. Under the action of the spray water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com