Solid-state instant tea granule and preparation method thereof

A technology for making granules and instant tea, which is applied in the fields of tea, tea extraction, food science, etc., can solve the problems of difficult to truly meet the taste requirements of tea drinkers, solvent residues, differences, etc. Water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

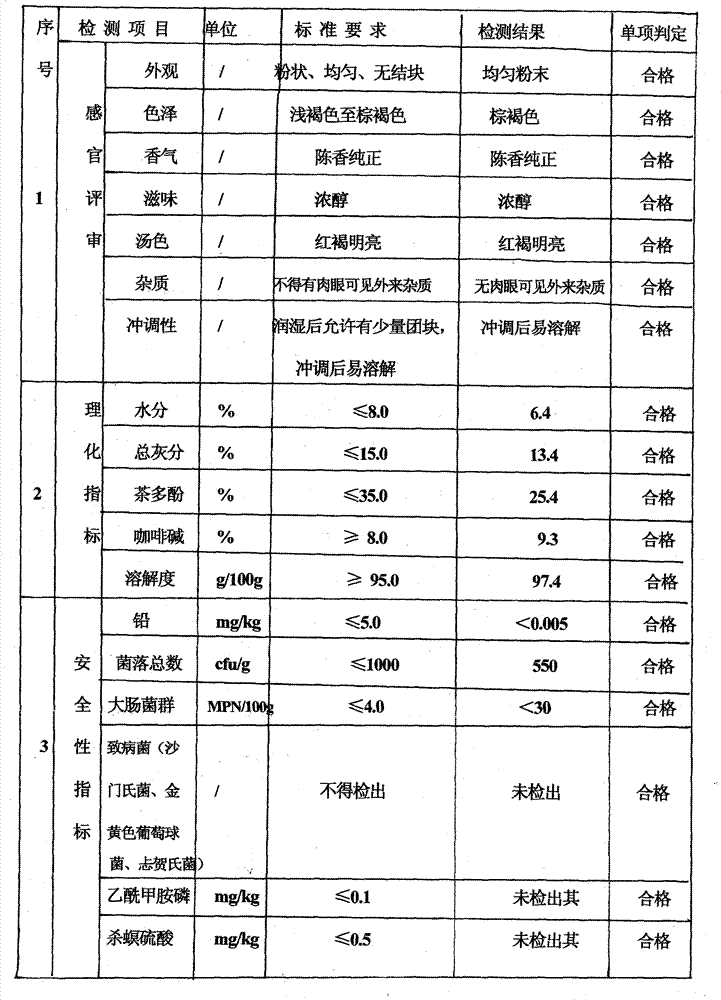

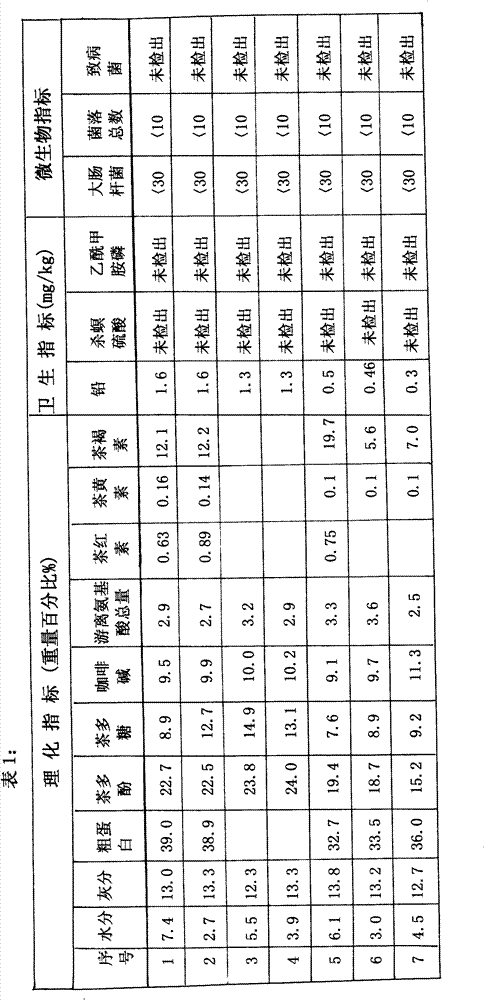

Embodiment 1

[0020] Example 1: Select 100kg of Pu'er tea as the raw tea, add water 8 times the weight of the raw tea, complete the extraction and boiling in a dynamic closed dynamic cycle, concentrate under reduced pressure for 5 hours, and reflux at the same time to extract the aged volatile oil of Pu'er tea. When the specific gravity of Pu'er tea concentrate is 1.1g / ml, filter, and the filtrate is transported to the top of the 40m high tower, the liquid pressure is 2MPa, the pressure is released suddenly and the atomization is in contact with the air with an inlet temperature of 130°C and a pressure of 0.5MPa. Heating for 5 seconds, when the temperature of the hot air drops to 98°C and the pressure is 0.4MPa, a hollow Puer tea granule with a diameter of 0.05-0.4mm is obtained, and the content of water and aged volatile oil in the hollow Puer tea granule is 2%-8%. , tea polyphenol content is 14%-25%, total ash content is 10%-16%, caffeine content is 7%-13%, solubility g / 100g≥95, tea polysa...

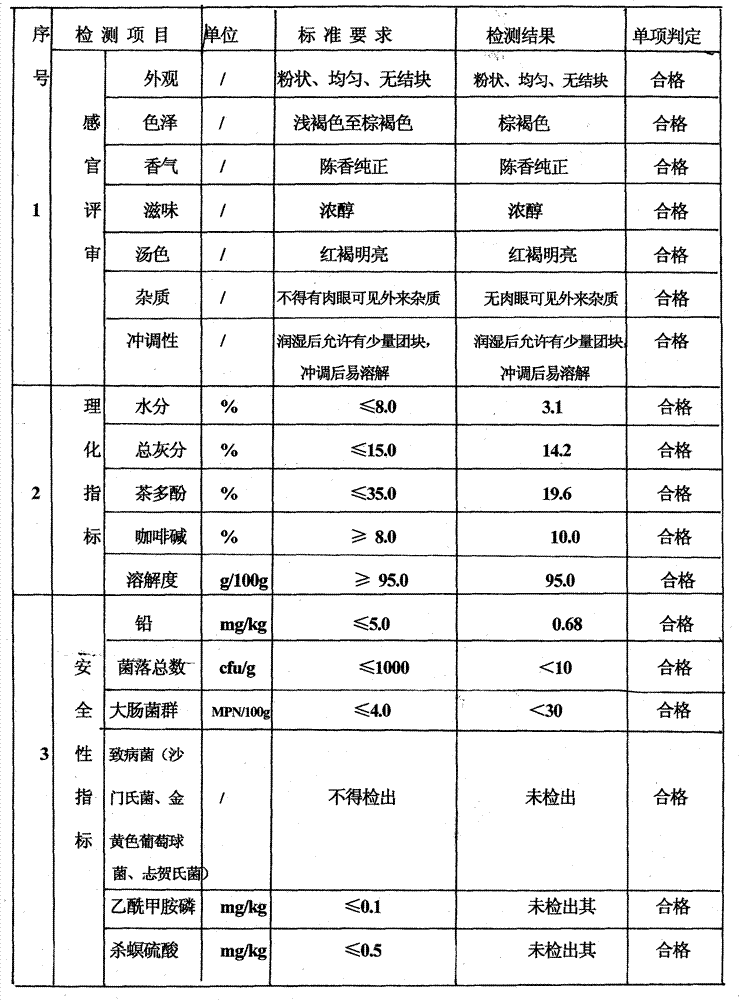

Embodiment 2

[0022] Embodiment 2 Take 100kg green tea as the raw tea, add water 16 times the weight of the raw tea, complete the lifting and boiling in a dynamic closed tower with dynamic stirring and circulation, and concentrate under reduced pressure for 8 hours. During the reflux process, the aged green tea aroma volatile oil is extracted simultaneously. When the specific gravity of the green tea concentrate is 1.5g / ml, filter, transport the filtrate to the top of a 30m high tower, pressurize the filtrate to 3MPa, let the filtrate suddenly release the pressure from the discharge hole and atomize, and the temperature of the other inlet is 160°C , contact with air with a pressure of 0.3MPa, and heat for 1 second. When the temperature of the hot air drops to 96°C and the pressure is 0.2MPa, hollow green tea particles with a diameter of 0.05-0.4mm are obtained. Hollow green tea granules contain 6% moisture and aged volatile oil, 14% tea polyphenols, 16% total ash, 13% caffeine, 16% tea polys...

Embodiment 3

[0024] Embodiment 3 Take 100kg of black tea and add 10 times of water, in the dynamic closed tower, the dynamic agitation and circulation are completed to extract and boil, and concentrate under reduced pressure for 7 hours. When the specific gravity of the black tea concentrate is 1.3g / ml, filter, the filtrate is transported to the top of the 20m high tower, pressurize the filtrate to 4MPa, let the filtrate discharge from the discharge hole, the filtrate suddenly releases the pressure and atomizes with another inlet temperature Contact with air at 150°C and a pressure of 0.4MPa, and heat for 4 seconds. When the temperature of the hot air drops to 97°C and the pressure is 0.3MPa, hollow black tea particles with a diameter of 0.05-0.4mm are obtained. Hollow black tea granules contain 8% water and aged volatile oil, tea polyphenols 14%, total ash 10%, caffeine 7%, solubility g / 100g ≥ 95, tea polysaccharide 10%, crude protein At 30%, the total amount of free amino acids is 2%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com