Automatic heavy-load equipment early warning implementation method based on decision tree

A realization method and automatic early warning technology, applied in the direction of AC network circuits, instruments, electrical components, etc., can solve problems such as accidents, economic losses, loss of load, etc., and achieve the goal of improving the level of automation, reducing the scope of influence, and reducing load loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

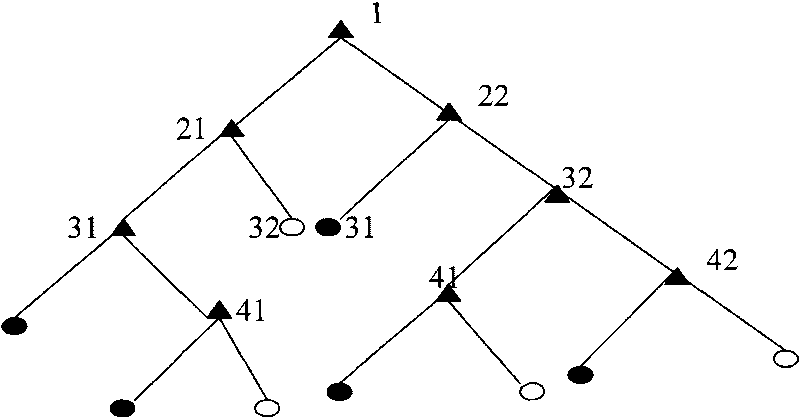

[0036] like figure 1 As shown, this embodiment includes the following specific steps:

[0037] The first step is to establish a monitoring group, set the overload action value AV, overload start value SV, and start reset value RV of each monitoring group;

[0038] Among them, the overload action value AV (action set-value) refers to the amount of warning required after the overload rate of the overload group equipment reaches a certain value; the overload start value SV (start set-value) refers to the overload group equipment After the load overload rate reaches a certain value, the start value of the heavy load group value is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com