Intelligent monitoring method for transmission shaft

A technology of intelligent monitoring and transmission shaft, which is applied in the field of transmission shaft monitoring, can solve the problems of complex test equipment, inability to measure signal transmission, and inability to meet online detection, so as to achieve the effect of protecting safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

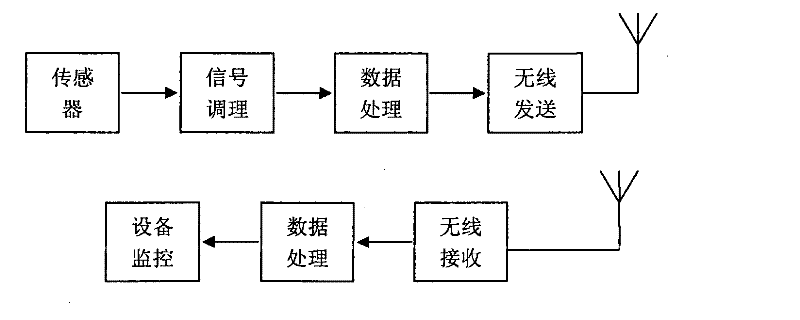

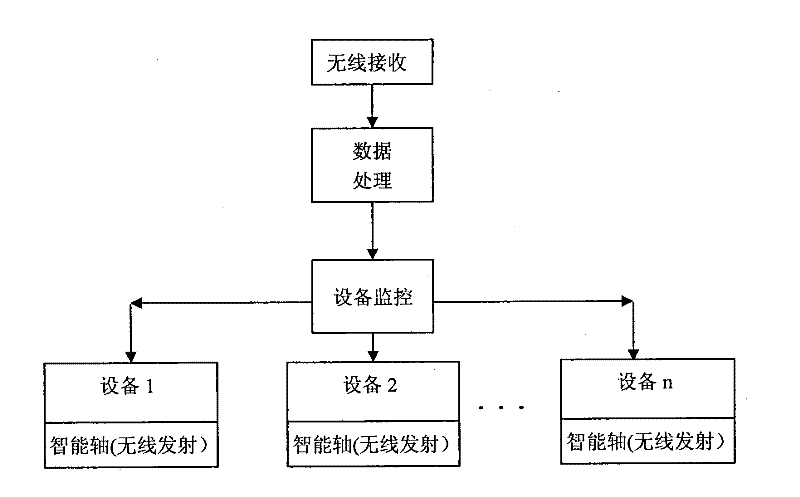

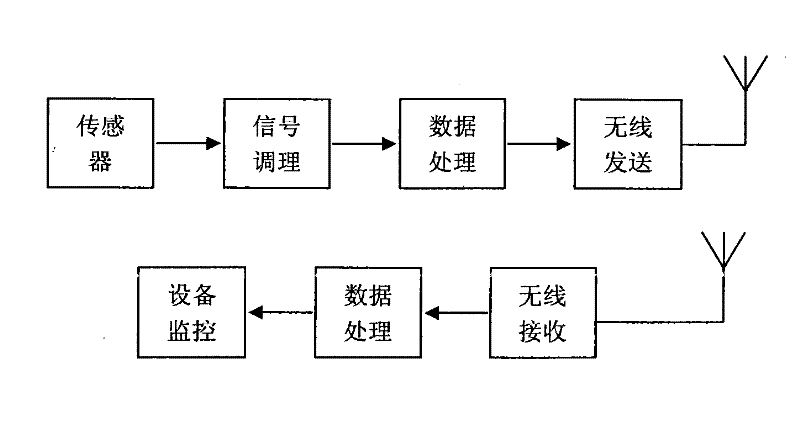

[0013] Such as figure 1 As shown, the present invention adopts micromachining technology to inlay strain gauge sensors, photoelectric speed sensors, data acquisition units and wireless transmitting devices on the transmission shaft, and integrates them with the transmission shaft. Each sensor is connected with the data acquisition unit, and the data acquisition unit is connected with the wireless transmitting device. It can intelligently detect the torque, speed and other parameters of the transmission shaft under the working state of the transmission shaft, and automatically output, according to the working state of the transmission shaft, control the operation of the equipment and protect the equipment.

[0014] When the equipment is running, the detection sensor detects the operation data of the transmission shaft and after conditioning, it is processed by the data acquisition unit and sent out continuously through the wireless transmitter. The receiving device is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com